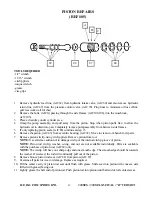

H.E.R.O. INDUSTRIES LTD.

330SES / 330SEL MANUAL - “B” VERSION

16

TROUBLESHOOTING

SITUATION

POSSIBLE CAUSE (REMEDY)

ELECTRIC MOTOR WON'T START/RUN

1. Unit unplugged or building circuit fuse is blown. (check, replace or reset fuse)

2. Pump under pressure. (reduce pressure setting by turning pressure control knob counter-clockwise,

trigger gun to relieve pressure).

3. Too light or too long of extension cord. (replace with correct cord. If distance greater than 100 feet,

obtain and install extra length of H.E.R.O. airless spray hose).

4. Unit's thermal overload switch has opened. (determine and correct cause of overheating).

ELECTRIC MOTOR STALLS/QUITS

1. See "Electric Motor Won't Start/Run

2. Drive belt is loose. (tighten drive belts by evenly turning belt tension bolts on either side of motor

clockwise. Loose belts generally emit loud squealing noises).

3. Unit primes, builds pressure, but pump “seizes” or “stops” when gun is triggered. ( loose belts, tighten).

TOTAL LOSS OF PRESSURE, HYDRAPULSE MEMBRANE MOVEMENT CANNOT BE STOPPED

OR ALTERED. (SEE "HYDRAPULSE MEMBRANE TEST")

1. Paint too thick. (thin paint according to manufacturer's recommendations).

2. Intake ball (ref# 13) worn or jammed opened/closed. (remove intake endcap (ref# 9) and ball guide

(ref# 16). Inspect intake ball, (ref# 13), to ensure it is free, round, and has no nicks or cuts. Inspect ball

guide for excessive "bashing out" on the internal walls. Excessive wear causes the ball to become "lost"

and unable to locate the seating surface. Inspect for foreign material jamming ball. Replace parts as

needed).

3. Intake seat loose/bypassing. (remove intake endcap, (ref# 9) and ball guide, (ref# 16). Inspect inlet

washer (ref# 10), for excessive compression. Remove seat (ref# 11), washer (ref# 10) for damage.

Inspect for any sign of material bypass between intake seat and endcap cavity.

NOTE;

The proper

alignment of intake parts, condition of intake washer, o-rings, combined with the correct bolt torque are

critical to the correct function of the intake valve. Replace the intake washer (ref# 10), each time the

endcap is removed.

4. Outgo valve ball (ref# 27) worn or jammed. (remove outgo valve, (ref# 32). Invert valve and unthread

outgo valve upper, (ref# 30), from outgo lower, (ref# 24). Remove crush washer, (ref# 25), outgo seat,

(ref# 26), outgo ball, (ref# 27), outgo cage, (ref# 28), outgo spring, (ref# 29), from outgo upper tunnel.

Inspect outgo ball to ensure that it is round and free of nicks or cuts. Inspect for foreign material

jamming ball. Inspect ball and cage for wear. Replace parts as needed).

5. Outgo valve (ref# 32) incorrectly assembled. (disassemble and reassemble outgo valve, closely

following detailed instructions on page 25).

TOTAL LOSS OF PRESSURE, HYDRAPULSE MEMBRANE HAS NO MOVEMENT OR

MOVEMENT CAN BE STOPPED. (SEE "HYDRAPULSE MEMBRANE TEST")

1. Hydraulic intake valve (ref# 60) defective. (remove hydraulic feed line, (ref# 62), from hydraulic

intake valve. Plug hydraulic feed line so hydraulic fluid does not drain. Remove hydraulic intake valve

from elbow, (ref# 59). Check hydraulic intake valve to ensure that it flows in one way only, into the

cylinder. Replace if necessary.

NOTE;

Item cannot be repaired ).