di Series User/Software Manual

21

www.heroninstruments.com

905-628-4999

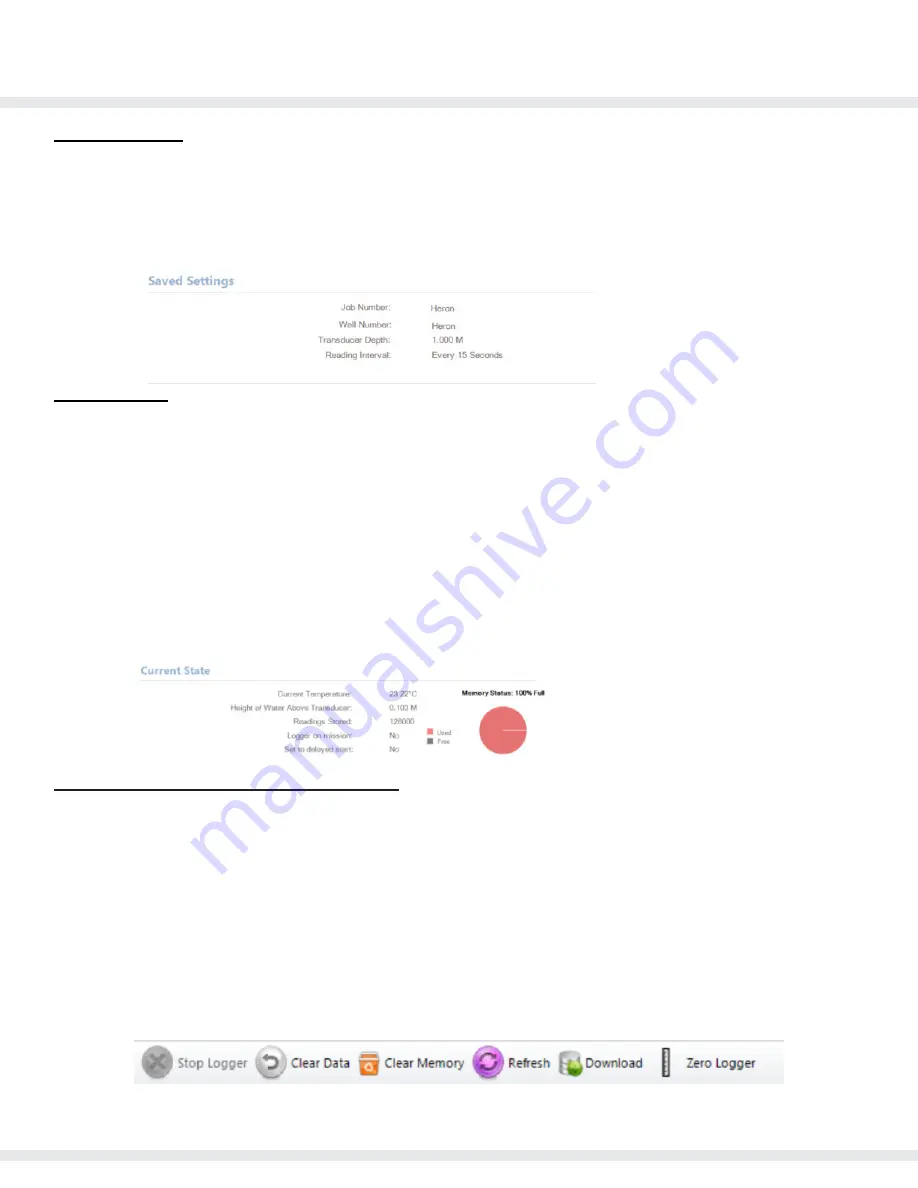

Saved Settings

Job Number:

5 Digits (Numbers/Letters) to Represent Job Site

Well Number:

5 Digits (Numbers/Letters) to Represent Particular Well

Transducer Depth:

The depth/distance the logger will be from the reference point (Ground level, Top

of casing etc.)

Reading Interval:

Refers to the frequency of readings (Seconds, Minutes, Hours, Log Time)

Current State

Current Temperature:

The temperature of the logger when it was connected in either

℃

or

℉

Height of Water Above Transducer:

The height of water above the transducer when it was

connected in either Meters or Feet depending on your computer’s settings.

Readings Stored:

Indicates how many readings are currently stored on the logger

Logger on mission:

Indicates if the logger is on a mission or not

Set to delayed start:

Indicates if the logger is set to start immediately or on a delayed start

Logger started on…

Indicates the date when the logger was started (only if the logger is currently on

a mission)

Memory Status:

shows your logger’s available memory in both a percentage and pie chart format.

Red = Used. Black = Free.

Logger Information - Secondary Tabs

Stop Logger:

Stop logger will cause the logger to stop taking recordings. All of your data will remain

in the logger’s memory. Note: you cannot restart a mission once stopped.

Clear Data:

Clear Data will erase only the recorded data from the logger, while leaving the device’s

settings the same.

Clear Memory:

Clear memory of all the recorded data from the logger, as well as the logger’s

settings.

Refresh:

Refresh causes the information displayed on the Logger Information page to refresh as if

being connected again.

Download:

Download causes the information being stored in the logger’s memory to be transferred

into the dipperLog Software (this will cause the “Data Reports” tab to open).

Zero Logger:

Zero logger resets the logger’s pressure sensor to ambient pressure.