The LED may additionally be used as an optical interface to read different

performance parameters (such as e.g. pulse counter, visualisation of the

flame’s signal intensity, serial number). In order to prevent, at very extreme

energy densities, that the characteristic flickering signals of the flame will

be interfered by the emitting radiation of the recirculation tube and other

glowing components, an optical filter precedes the real light sensor. It

dims the appearing radiation in the background in a partial region of the

spectrum so that the usable flame signal appears comparatively stronger.

Misinterpretations that under extreme conditions can also lead to unsafe

operating conditions are also avoided.

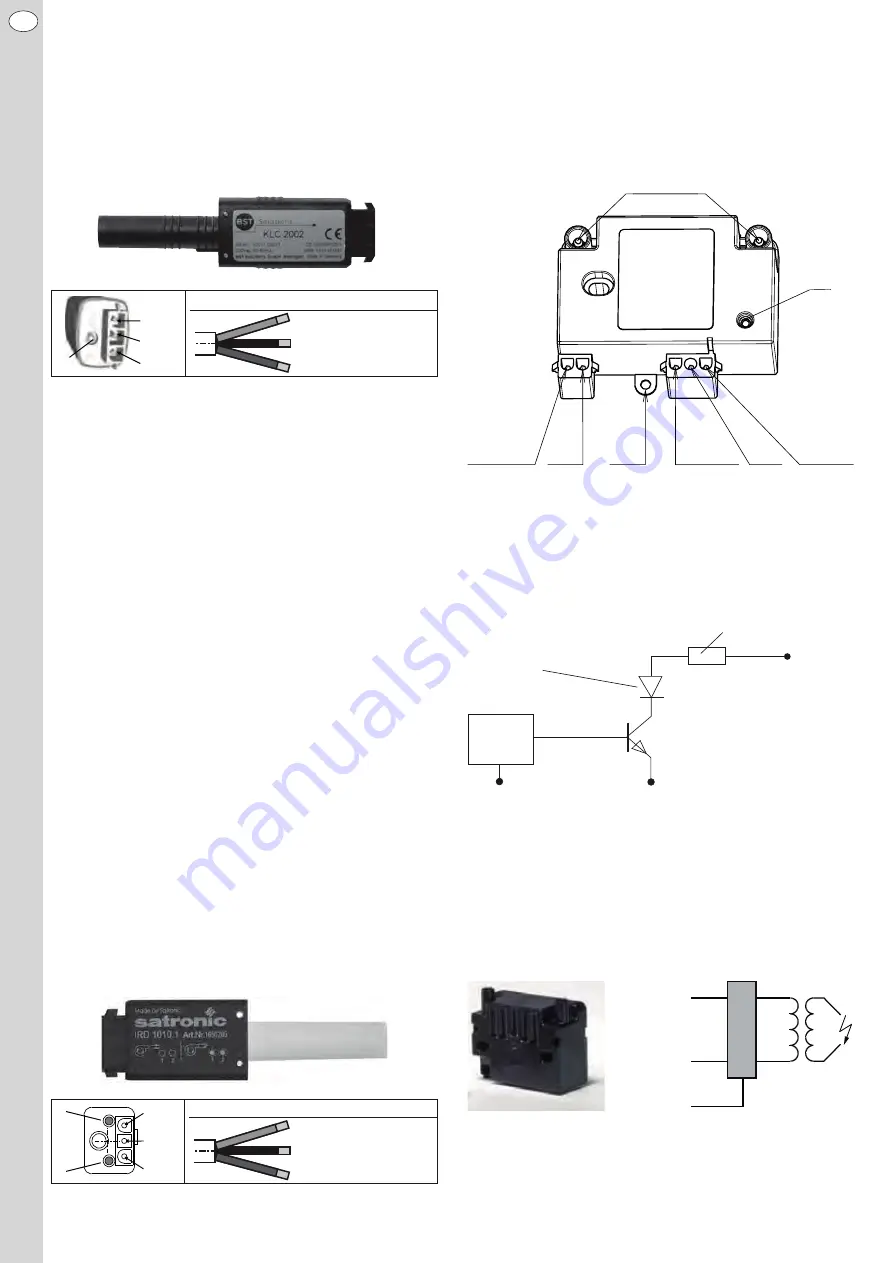

BST Solutions KLC 2002 flame detector.

Optical flame detector, IRD 1010.1

Like the KLC 2002, the principle of the IRD 1010.1 optical flame detector

(by Honeywell) is based on the detection of the alternating part of the in-

frared radiation emitted from the flame. However, the separation between

the direct and alternating components of the radiation is lower resoluted

in comparison with the sensor KLC 2002. A proportion of radiation with a

constant frequency may also be misinterpreted as flame. A flame rupture

on a very strongly glowing re-circulation pipe will be deteced a bit later

due to the combined effects towards the KLC 2002 flame detector. The

use of the IRD 1010.1 flame detector in connection with the LOA 24 firing

unit by Siemens has been approved in accordance with EN230:1991.

There is no approval in connection with the LMO 14 firing unit. Therefore

this combination is not deliverable.

The infrared cell and the pre-amplifier of the IRD 1010.1, together with the

evaluation electronics, are integrated in the housing of the flame detector.

On the rear side of the housing of the IRD 1010.1 flame detector are two

LED’s for the status display, as well as a setting screw for adjustment of

the sensitivity.

Adjustment of the sensitivity of the IRD 1010.1 flame detector

LED 1 has the function of a warning diode. A secondary light is available

if LED 1 is lighting up or flickering during the pre-ventilation. If such fli-

ckering occurs during the operation of the burner this means that the

flame signal is too weak. LED 2 indicates the respective switching state

of the flame detector (ON: flame signal is emitted; OFF: no flame signal

emitted).

For adjusting the sensitivity of the IRD 1010.1 to the respective operational

conditions we recommend the following procedure:

Prior to putting the burner into operation you should first set the adjust-

ment screw for the sensitivity of the flame detector to the maximum value

(scale value 7). After starting the burner successfully carefully turn back

the adjustment screw until LED 1 is flickering. Subsequently the sensitivity

is increased so that both LED’s are lighting up. You should then start the

burner again. You should check that LED 1 is not flickering during the pre-

ventilation. For safety reasons make sure that the sensitivity is not adjus-

ted higher than necessary.

Both LED‘s ON:

burner in operation

Both LED‘s OFF:

burner in pre-ventilation

Honeywell IRD 1010.1 flame detector

Accumulation of cables

Blue

Black

Brown

L E D

Black, switching output, FL

Brown, power supply, L1

Blue, N

Accumulation of cables

L E D 1

L E D 2

Black, switching output, FL

Brown, power supply, L1

Blue, N

1 1

2 2

3 3

4 4

5

5

6

6 7

1 1

2

Blue

Black

Brown

Electrical ignition unit with integrated ionisation flame monitoring,

ZTÜ

At the electrical ignition unit with ionisation flame monitoring ZTÜ (Beru)

one of the two existing ignition electrodes is used as an ionisation elect-

rode to monitor the flame.

For evaluation of the signal a circuit element, similar to the optical flame

detector, is integrated inside the ignition unit that displays the presence

of a flame through a high/low signal. As a result the ignition unit with flame

monitoring, as well as the optical flame detector, are usable with the same

burner control.

An LED in the housing of the ignition unit indicates the operating state of

the ionisation flame monitoring:

LED is OFF:

Ionisation flame monitoring is carrying no cur-

rent or faulty electrical connection.

LED is flashing:

Ionisation flame monitoring is active, no flame

has been detected.

LED is permanently ON:

Ionisation flame monitoring is active, flame

has been detected.

Output wiring of BST Solutions KLC 2002 flame monitor/Beru ZTÜ /

Honeywell IRD 1010.1

2.5 Ignition device

If an optical flame detector is used the ignition of the mixture occurs

through a separate ignition device (Danfoss EBI 4). An earth connection

is located in the primary connection socket to achieve a low electro-mag-

netic interference emission, i.e. the connection socket has three-pole

(phase, neutral wire and earth). Consequently the lateral earth lug, that is

used at the ignition unit with integrated flame monitoring is absent.

2.6 Oil firing unit

The control and monitoring of the burner occurs alternatively by an elect-

romechanical oil firing unit, Siemens LOA 24 (approval according to DIN

EN 230:1991), or by an electronic oil firing unit, Siemens LMO 14 (approval

High voltage

Blue,

N

Blue,

N

PE,

Earthing

Brown,

voltage

supply, L1

Black,

switching

output,

FL

LED

Brown,

Ignition

"ON": 230 V AC

"OFF": 0 V

Brown, power supply, L1

Black, switching output, FL

“Digital signal“

When applying the voltage:

- Flame OFF, no potential, “high“

- Flame ON, “low“

With the alternating voltage at FL the signal is

rectified through the transistor, and the diode

is connected in series as well (to enable a

connection to the burner control unit with ionisation

flame monitoring).

Blue, N

Signal

Electronic strobe

Flame sensor

Series resistor to protect the transistor

Electronic control

at the flame

sensor

Blue, GND

Brown,

voltage supply, L1

Ignition

"ON": 230 V AC

"OFF": 0 V

PE, Earthing

50/60 Hz

20 kHz

26

EN