1.

Technical Data

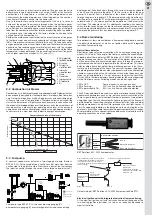

1.1 Range of models

Type

Oil nozzle

Oil throughput

Fuel power

(US gal/h 80°H)

m

in kg/h

Q

F

in kW

HLZ 45 AV 17 G1

0,30

0,84 – 1,52

10 – 18

HLZ 45 AV 17 G1

0,35

1,10 – 1,85

13 – 22

HLZ 45 AV 19 G1

0,40

1,18 – 2,02

14 – 24

HLZ 45 AV 19 G1

0,45

1,35 – 2,53

16 – 30

HLZ 45 AV 22 G1

0,55

1,69 – 3,04

20 – 36

HLZ 45 AV 22 G1

0,60

1,94 – 3,37

23 – 40

HLZ 45 AV 24 G1

0,60

2,19 – 3,54

26 – 42

HLZ 45 AV 24 G2

0,65

2,28 – 4,05

27 – 48

HLZ 45 AV 24 G2

0,75

2,45 – 4,38

29 – 52

HLZ 45 AV 24 G2

0,85

2,78 – 4,72

33 – 56

HLZ 45 BV 27 G2

0,85

2,95 – 5,06

35 – 60

HLZ 45 BV 27 G2

1,00

3,29 – 5,56

39 – 66

HLZ 45 BV 31 G2

1,10

4,05 – 6,24

48 – 74

HLZ 45 BV 31 G2

1,25

4,22 – 6,91

50 – 82

Image: Model code H L Z 45 A V 19 G1

H

R

Herrmann

L

R

Light oil burner

Z

R

Two-stage

45

R

Series

A

R

Mixing device

V

R

Pre-heater

19

R

Diameter air nozzle (17, 19, 22, 24)

G1

R

Size of blower (G1 HRG 134, G2 RG 148)

1.2 Certification

European Standard (EN) 267:2009, class 3

1.3 Operating range

The operating range diagram of an oilburner describes the maximum fur-

nace pressure dependig on the oil mass flow. For a reliable start up the

burner may alternatively be started in the first or second stage. While it is

preferable for the burner to start in the lower power area in the second

stage, a start in the middle or upper power area in the first stage is ad-

vantageous. The diagram below also shows the corresponding starting

points. The range of operation has been determined on a test boiler in ac-

cordance with DIN EN 267:2009 and relates to a height of 100 metres

MSL, as well as to a room temperature of 20ºC. The maximum achievable

firing rate depends on the respective starting resistance of the heating

system. This is influenced by the geometry of the heating system and the

heat exchanger, as well as the flue gas system.

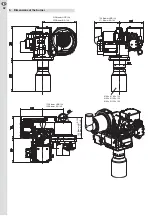

1.4 Serial scope of delivery

1 Oil burner

1 Unit flange

1 Seal for the flange

2 Odour-proof oil tubes (length 1,500 mm)

4 M8 x 30 fastening screws for unit or shift flange including washers

1 Hexagon key, nominal diameter 4 mm

1 7-pole/4-pole socket – part of Euro female connector in accordance

with DIN 4791:1985-09 (plug connectors for the boiler are not included

in the scope of delivery) 2-pole Rast-5 plug for the remote unlatching

1 Airborne sound absorber

1 Assembly and operating instructions

HLZ 45 AV 19 G1

HLZ 45 AV 17 G1

HLZ 45 AV 22 G1

HLZ 45 BV 27 G2

HLZ 45 AV 24 G2

6,0

6,5

7,0

7,5

HLZ 45 BV 31 G2

HLZ 45 AV 24 G1

Operating range

Fur

nace pr

essur

e in mbar

2. Stufe

(starting point)

1. stage

(starting point)

1. stage

2. stage

Oli mass flow in kg/h

1.5 Fuel

-

Heating oil EL in accordance with DIN 51603-1

-

Heating oil EL, low sulphur, in accordance with DIN 51603-1

-

Heating oil EL, bio 10 (bio heating oil in accordance with

DIN SPEC 51603-6, heating oil EL, low sulphur, with up to 10% portion

of FAME, corresponding to the quality requirements of DIN 14214)

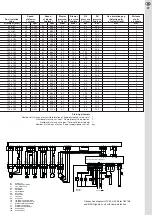

1.6 Components

Components

Manufacturer

Designation of model

Blower

ebm-papst

HRG 134 / RG 148

Motor

ACC

EB 95 C 35 / 2

Oil pump

Danfoss

BFP 52 E L3

Oil pre-heater

Danfoss

FPHB 5, PTC 50,

T 60/32, 30-90 W

Ignition

Danfoss/Beru

EBI 4/ZTÜ with flame

monitoring

Flame control

BST-Solutions

Wide Band Flame

Detector KLC 2002

Beru

Ignition unit with flame

monitoring, ZTÜ

Firing unit

Elster

CM 168

Communication interface (CI)

Herrmann

CI 1

1.7 Electrical data

Nominal voltage

230 V ~50 Hz

Starting power

approximately 180 W

Operating power

approximately 130 W–270 W

Contact rating of heat valve and switch 6A~ at minimum

1.8 Acoustic emissions

The HLZ 45 burner is equipped in series with an airborne sound absorber.

By using this sound absorber the sound pressure level can be reduced to a

maximum burner output from 68 dB (A) [without sound absorber] to 60 dB

(A) [with sound absorber]. These values have been detected with a measur -

ing instrument with a degree of accuracy 2 in accordance with IEC 60651

(International Electro-technical Commission) and at a horizontal distance of

2 metres.

1.9 Packing

Individual packaging (carton), base x height: 400 x 400 x 465 mm

Individual weight of the burner without packaging: approximately 12.0 kg

Individual weight of the burner with packaging: approximately 13.0 kg

Collective packaging (18 single cartons on an Euro pallet), base x height:

1,200 x 800 x 1,700 mm

Weight of pallet: approximately 254 kg

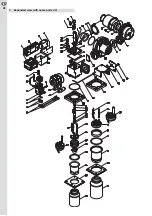

2.

Functional description

The HLZ 45 oil burner is designed as two-stage blue flame burner for ope-

ration with EL heating oil. A two-stage gear pump is used for fuel injection.

The injected fuel mass flow depends on the size of the nozzle and the in-

jection pressure adjusted at the respective pressure balance valves of the

respective load stage (6bar<p

E

<25bar). For adjustment of the air volume flow

to the injected fuel mass flow a regulating speed blower is assigned. During

the operation of the burner and before each burner start up the fuel is heated

to a temperature of approximately 70º C in an electric fuel heater. Through

this process, temperature and quality conditioned fluctuations of the fuel

viscosity that have an effect on the spraying process and the fuel flow rate

are decreased. The fuel spray is ignited by an electric spark that is formed

by the application of high voltage between two initiating electrodes.

Subsequently we will go into the function of the individual sub-systems

in more detail.

2.1 Mixing device

A blue flame burner mixing device is used to burn the mixture. The fuel

spray that escapes from the nozzle evaporates before the actual reaction

of combustion by a mixture of hot flue gases. The low level of temperature

within the evaporating zone and the water content of the drawn-in flue ga-

ses prevent the formation of soot. The intensity of the backflow is indicated

by the rate of recirculation that measures the proportion of the recirculated

flow of flue gas of the entire gas mass flow. Low rates of recirculation fa-

vour the formation of soot. The solid state of soot particles confers a yellow

colour to the flame. An increase in the recirculation of flue gas reduces the

rate of soot formation and ultimately results in a completely soot-free flame

that emits a hardly visible blue flame to the human eye.

20

EN