33

EN

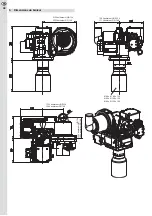

10. Accessories

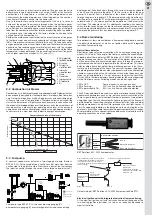

10.1 Portable pump tester

For de-airing the suction pipe and for measuring the injection/suction

pressure of the pump we would recommend the tools from our portable

pump tester (order no. 10042.00001) that consist of:

1 Case coated with foamed material

10042.00008

2 Pressure gauge (0 - 25 bar)

10042.00002

3 Vacuum gauge (-1 - 0 bar

10042.00003

4 Flexible pressure gauge extension with

1/8” screwed nipple

10042.00004

5 De-aeration device 1/8“ with shut-off

10042.00005

6 Reducing adaptor with 8 x 2mm O-ring

10042.00006

7 Reducing adaptor for vacuum gauge

with 8 x 2mm O-ring

10042.00007

10.2 Screw plug for the return flow connection of the

pump

When converting the pump to a one-line operation make sure to seal the

return connection with a screw plug (order no. 10019.00006) and remove

the shift screw in the junction canal between the pressure and the suction

side (cf. chapter 3.5).

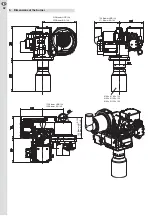

10.3 PC connecting tool

The PC connecting tool

CoCo PC mobile provi-

des a comprehensive re-

presentation of the

factory given perfor-

mance parameters, as

well as clearly extended

diagnosis possibilities in

comparison with the

communication interface

CI1. In the event of a

burner failure goal-di-

rected research into the

causes of this failure, as

well as a statistic error

report, is possible. In ad-

dition to this the PC user

interface offers a very

convenient setting of the

blower’s rotational speed

for the first and second

power stage.

For this purpose you

should connect the bus

output of the firing unit

through an interface

adaptor with the USB in-

terface.

The connecting tool, consisting of an interface adaptor, USB cable, bus

cable, output software (CD) and operating manual, is available under the

order no. 10042 00013.

10.4 Burner chip card

The burner chip card is a memory element that can be inserted into the

firing unit and is used to re-parameterise the firing unit. Whereas only the

blower’s rotational speed at the first and second power stage can be

changed through the communication interface CI1 or the connecting tool

in comparison with the factory’s basic setting, the burner chip card is a

completely new parameterisation of the firing unit. The burner chip card

is intended to change the parameters of the system on-site, or in order to

establish customised, parameterised models from a basic variety of the

firing unit depending on the type of use. It should be taken into conside-

ration that after a burner chip card has been inserted into the firing unit it

should only be operated with this or another burner chip card.

The following procedure should be taken into consideration when you in-

sert the burner chip card into the firing unit:

1. Interrupt the firing unit from the voltage supply (by unplugging the 7-

pin Euro plug).

2. Insert the burner chip card.

3. Connect the firing unit with the voltage supply (by plugging in the 7-

pin Euro-plug).

4. Confirm the note “50” (“Start copying”) at the communication interface

by pressing the “Reset” button.

5. Confirm the note “52” (“Activation of new parameter set”) at the com-

munication interface by pressing the “Reset” button.

After these steps, the firing unit undertakes a reset and uses the new set

of parameters thereafter.

Burner control

Burner Chip Card

11. Customer service

For further information on the burner and for ordering spare parts please

do not hesitate to contact our Customer Service Department at:

Herrmann GmbH u. Co. KG

Phone: 00 49 7151 98928-0, Fax: 00 49 7151 98928-49

Email: info@herrmann-burners.de

Interface adaptor

BUS cable

USB cable