13

Maintenance instructions for models mounted on the face of a vertical return

duct, side of a horizontal return duct, or mounted behind a wall using

discharge extension

Your humidifier is constructed from quality materials to assure superior

performance during normal operation. The motor bearings are permanently

lubricated and do not require oiling. The motor is also thermal overload

protected against extreme conditions.

To clean the unit:

1.

Turn the power to the furnace OFF or turn off the electric switch to the

humidifier, if provided.

2.

Disconnect the humidifier motor leads.

3.

Turn off the humidifier water supply from the saddle valve and remove

water line from humidifier.

4.

Remove the humidifier from the wire mounting bracket.

5.

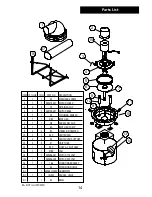

Remove the discharge dome from the humidifier by pressing on the sides

of the dome and lifting upward.

6.

Lift the entire atomizing assembly from the water reservoir pan.

7.

Remove the pump from the end of the impeller shaft. If the pump is stuck

in the motor drive shaft, run hot water over the end of the shaft for a

few seconds to loosen the pump.

8.

Flush water through the impeller tube, ensuring that the six holes at the

top of the impeller tube are open and clear of mineral deposits. A pipe

cleaner works well for this cleaning operation.

Note: The impeller tube and pump can become clogged by algae

formations prevalent in certain water sources. The addition of 10 drops

of bleach to the water reservoir pan each week is advisable.

9.

Replace the pump into the impeller shaft.

10. Carefully rotate the impeller to ensure it turns freely. Do not force the

impeller shaft to turn or breakage could result.

11. With the atomizing assembly removed, clean the water reservoir pan

thoroughly. We suggest either a water/white vinegar solution or liquid

humidifier cleaner.

12. Reassemble and remount the humidifier by reversing steps 6, 5, and 4.

13. Reconnect the water line and motor leads to the humidifier, turn on the

water supply from the saddle valve and restore electrical power.

Maintenance