6

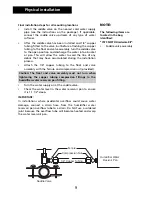

Mounting on the face of a vertical return duct

or side of a horizontal return

1. Mount the installation template on the side of the

cold air return air duct with the center line of the

template lined up with the center line of the return

air duct. The narrow side of the duct may be used if

space permits.

2.

Check the template with a level to ensure proper

installation of the humidifier.

3.

Drill (4) 1/8” diameter holes (as shown on the

template) for mounting the wire bracket with sheet

metal screws and flat washers provided.

4.

Cut out the circle marked on the template. Do not cut

this opening undersized.

5.

With a hammer and a heavy piece of metal,

straighten the metal edges to prevent injury to

yourself and damage to the humidifier.

6. Fit the rubber channel around the cut-out to cover

the rough edges of the hole and trim to fit.

7.

Attach the wire mounting bracket to the duct with (4)

#10 sheet metal screws and flat washers (provided).

8.

Move the side adjusting arms vertically until the shelf

of the wire mounting bracket is level.

9.

Mark the duct for securing adjusting arms and drill (2)

1/8” holes. Fasten the arms in this position with (2)

#10 sheet metal screws and flat washers (provided).

10. The float and valve assembly have been factory

adjusted to maintain 1-1 1/2” of water in the water

reservoir pan at normal water pressure. If necessary,

bend the float arm to the required position to

maintain the water level at other water pressures.

11. Before mounting the humidifier in its final position,

carefully rotate the impeller assembly by hand to

ensure it rotates freely. Position the humidifier on the

wire mounting bracket with the float and valve

assembly connection facing the most convenient

location. Be sure that the water reservoir pan feet do

not rest on the wire bracket and that the water

reservoir pan is level.

12. The discharge dome should approach the opening in

the duct, however, it should not extend into the duct.

There will be no heat loss, due to the negative

pressure of the cold air return duct (the air flow will

create a vacuum in the duct).

Physical installation

NOTE:

The following items are located

in the carton:

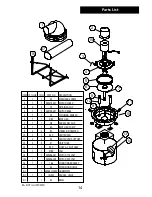

• Bottom pan

• Atomizing assembly

• Discharge dome (plastic)

• Wire mounting bracket

The following items are located

in the bag identified

“707 SM/STD Hardware Kit”:

• Template

• (6) #10 x 3/4” screws

• (6) #10 flat washers

• Rubber channel

Cold air return duct

Wire mounting bracket

Bracket should be level

Rubber channel

Discharge

dome