8

11. Before mounting the humidifier in its final position, carefully rotate the impeller assembly

by hand to ensure it rotates freely. Mount the humidifier on the wire mounting bracket with

the float and valve assembly connection facing the most convenient location, but providing

the least obstruction to traffic. Be sure that the water reservoir pan feet do not rest on the

wire bracket and that the water reservoir pan is level.

12. Locate the discharge hole on the outside wall. Mount the outside wall hole template using

the center of the pilot hole for reference. A pencil may also be used to find the previously

drilled pilot hole. When the outside wall hole template is secured, cut the hole in the

outside wall, using a saber saw or equivalent, for the discharge nozzle.

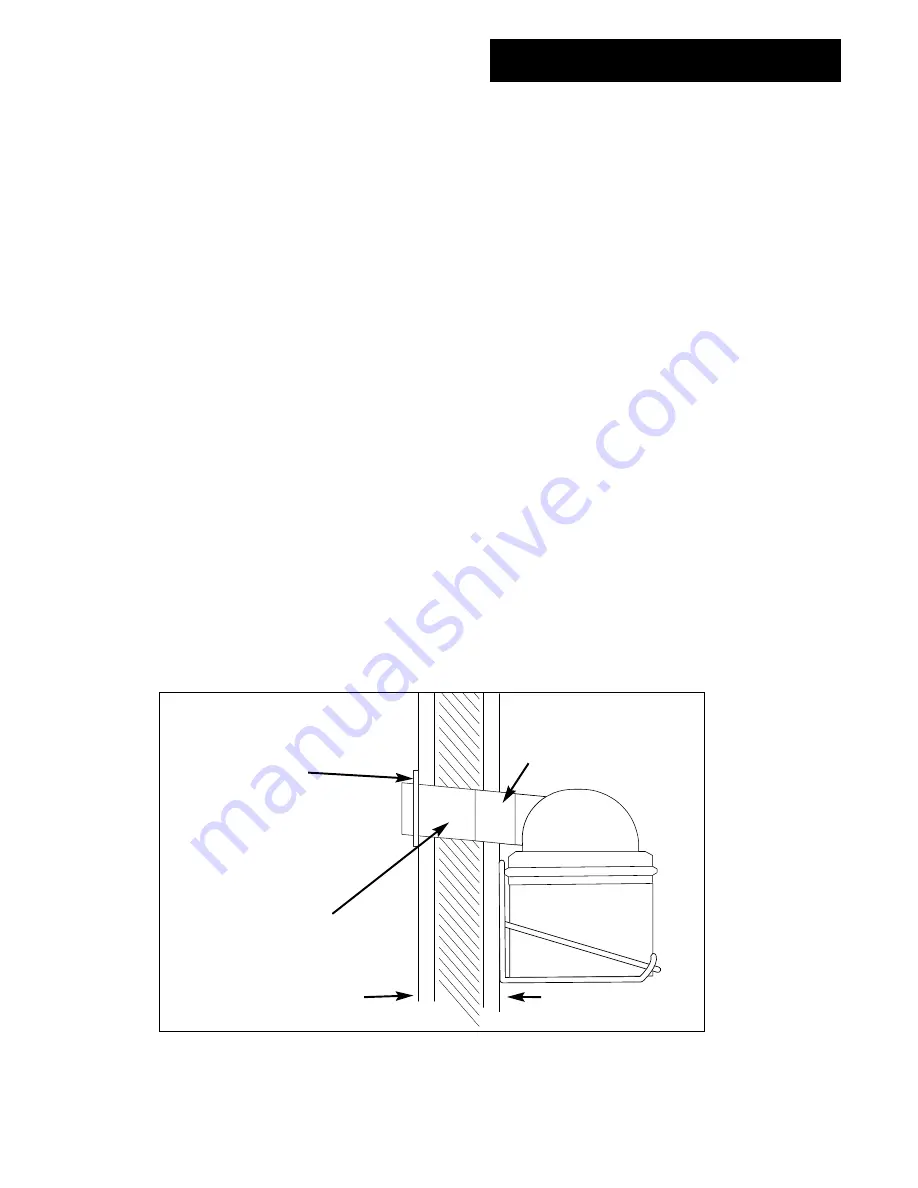

13. Measure the total thickness of the wall, not the stud thickness, but the distance between

the surfaces of the inside and outside walls.

14. The length of the discharge extension nozzle (provided) will be 2 5/8” long PLUS the total

wall thickness as determined in the previous step. Cut the extension nozzle to length on the

square end. The opposite end of the extension nozzle is angled to provide the correct fit

with the outside wall.

15. Fit the flexible connector sleeve onto the discharge dome and fasten securely with one (1)

hose clamp provided.

16. Insert the angle cut end of the extension discharge nozzle into the hole cut into the inside

wall, making sure the white line is pointed UP. Connect the extension discharge nozzle to

the discharge dome’s flexible connector sleeve. The angle cut end of the extension discharge

nozzle should be adjusted so that 5/8” of the tube extends past the outside wall. Secure in

position with one (1) hose clamp.

17. Install the cosmetic bezel onto the discharge side of the extension discharge nozzle. Making

sure that the bezel sits flat against the wall, 1/4” of the extension discharge nozzle should

extend past the bezel. This setup is necessary to prevent excessive condensation.

Physical installation

Connector sleeve

Inside wall

Outside wall

Discharge extension

nozzle

Cosmetic bezel