I n s t a l l a t i o n , O p e r a t i o n , & M a i n t e n a n c e M a n u a l

11

www.herrmidifier-hvac.com

9.

After approximately a five-second delay, the fill valve

energizes and water begins to fill the cylinder to the preset

amp level or cylinder full condition, depending on the

incoming water supply. When starting up the unit, it is best

to put an amp clamp on the power leg that passes through

the toroid transformer. Ensure that the humidifier fills

to “cylinder full” (approximately 1.5” from the top of the

cylinder), or that the amperage reaches the data label

maximum and the fill valve de-energizes.

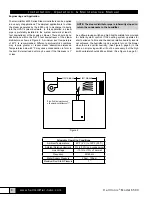

10. All units are equipped with a drain tempering feature which

mixes cold fill water with the hot drain water to protect drain

piping.

Unit is factory set with drain tempering inactive.

To activate, move drain tempering jumper to ON

position from circuit board.

(See Figure 13.) Depending

on your fill water pressure, some adjustment of the fill

metering valve may be necessary to ensure drain water of

less than 140°F. (See Figure 11.)

11. Reset control and high limit humidistats to their desired

settings. Refer to instructions supplied with humidistat.

NOTE: The capacity of the humidifier can be adjusted be-

tween 50% and 100% of the maximum level by adjusting

the Capacity Adjustment Pot on the main circuit board.

CAUTION!

Inadequate airflow may allow humidity to collect in areas

causing condensation.

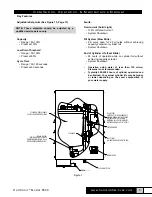

Herrtronic

®

Model 6500

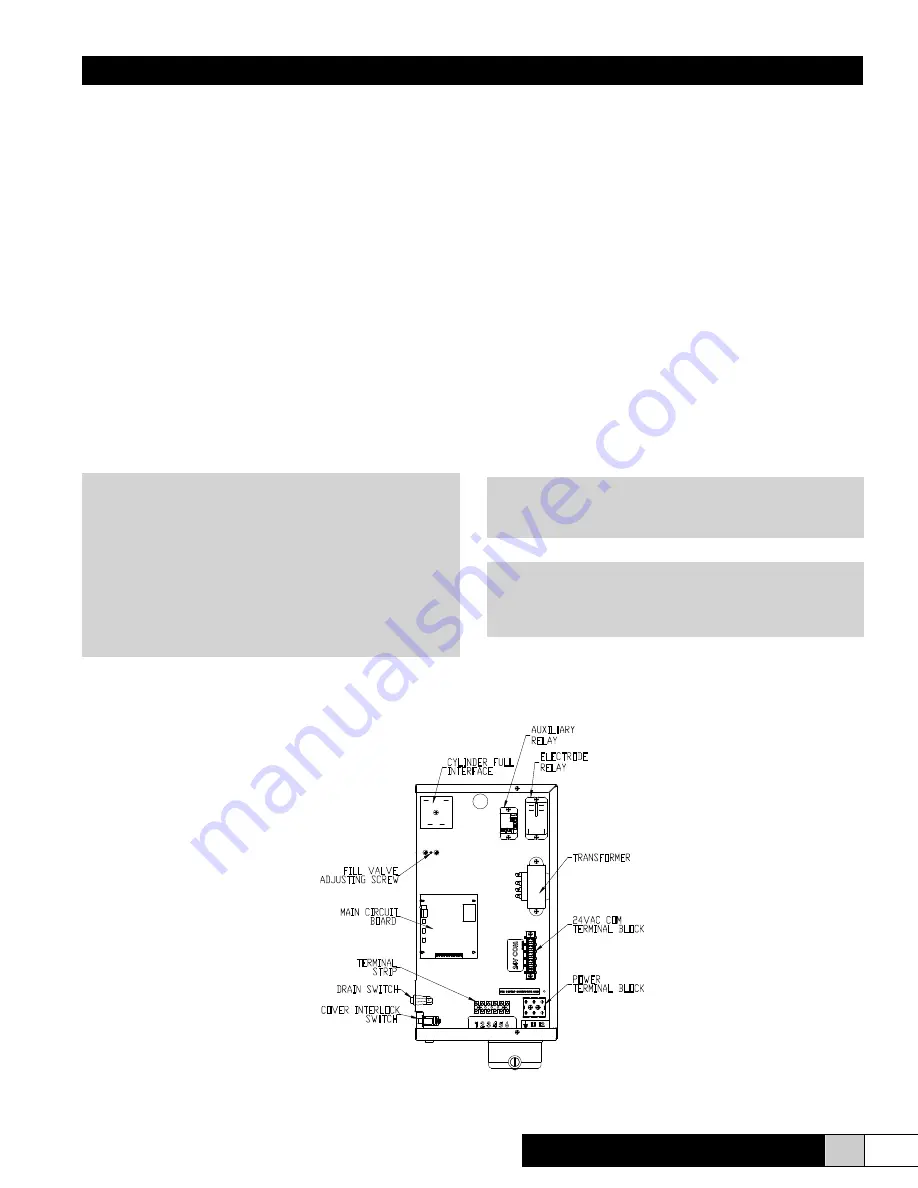

CYLINDER FULL

INTERFACE

ELECTRODE

RELAY

FILL VALVE

ADJUSTING SCREW

POWER

TERMINAL BLOCK

TRANSFORMER

24VAC COM

TERMINAL BLOCK

TERMINAL

STRIP

MAIN CIRCUIT

BOARD

AUXILIARY

RELAY

DRAIN SWITCH

COVER INTERLOCK

SWITCH

NOTE: If upon initial start-up of this humidifier the cylin-

der is slow in heating and/or the service light continues

to come on, drain the tank to 1/4 full. Turn off power at

disconnect, obtain some Alka-Seltzer tablets and crum-

ble 1/2 of one tablet (Alka-Seltzer) into the grey fill tee.

Then turn the disconnect on and run the unit. If you have

had to use this step on a 230V unit (6500-2), it is advisable

that you order a GT-176-1 replacement cylinder rather

than the standard replacement cylinder in the future so

this procedure will not need to be repeated.

SECTION IV OPERATING INSTRUCTIONS

Start-up Instructions

1.

Check that the humidifier is properly mounted and level.

2.

Check that the water fill and drain are properly connected.

3. Check that the correct voltage and amperage service are

supplied.

4. Check all controls are wired properly.

5. Check that the steam distributor is properly installed and

that the steam hose has been properly routed without any

kinks or flat spots.

6.

With power OFF, double check all electrical connections

and plumbing connections to insure that they did not loosen

during shipment.

7. With the control and high limit humidistats at their lowest

settings, turn on the main disconnect. The unit should not

begin operation.

8. Turn the control and high limit humidistats up to their highest

setting. The relay should energize.

Figure 11 (View in from Right Side of Unit)