I n s t a l l a t i o n , O p e r a t i o n , & M a i n t e n a n c e M a n u a l

15

www.herrmidifier-hvac.com

Herrtronic

®

Model 6500

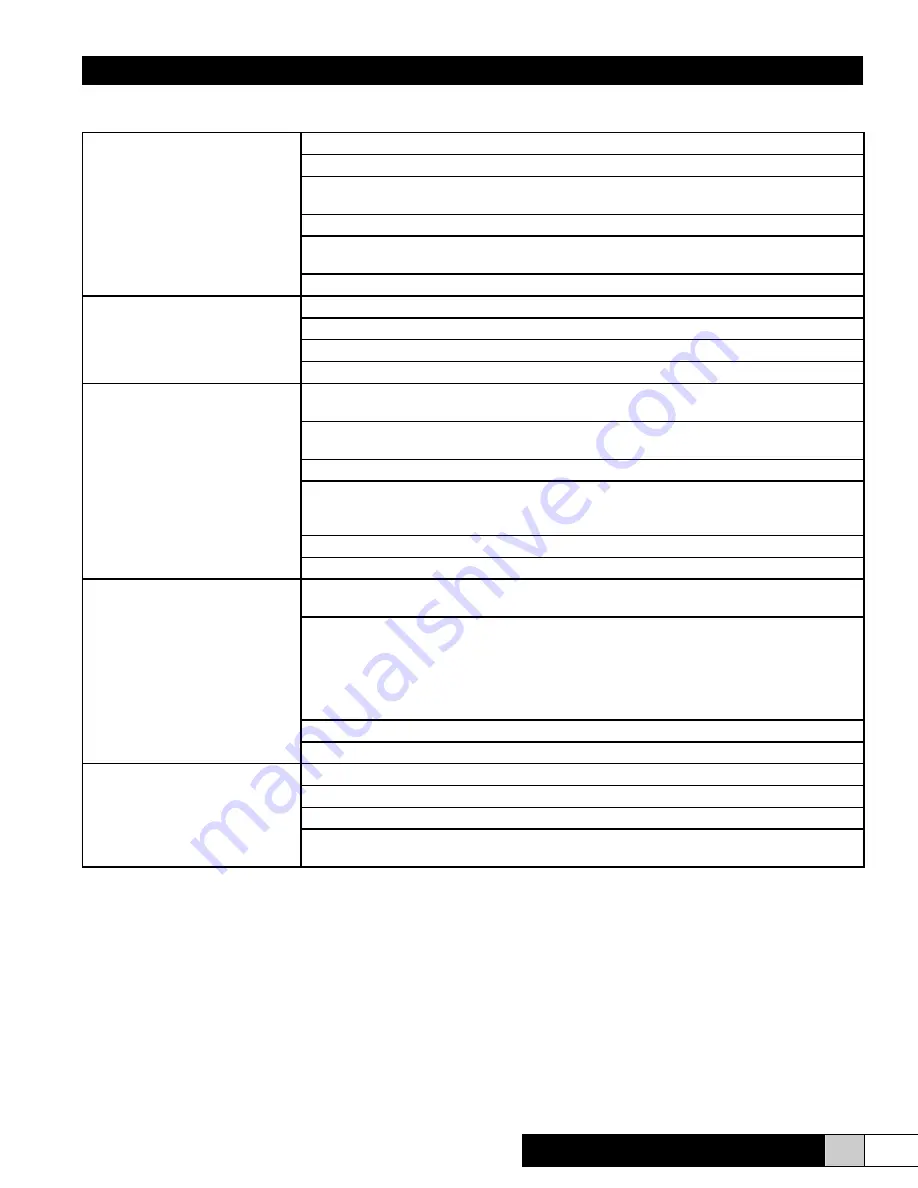

Non-Fault Activated Problems

Humidifier turned ON but will not

operate

Check power supply.

Check circuit breaker.

Check connector J1 on the circuit board and ensure that it is plugged into the circuit board

properly and that no wires are loose.

Ensure that there is 24 VAC between pole #9 and #11 connector J1. If not, check wiring.

Place jumper between controls wiring terminal strip #3 and #4. If unit operates, check controls

settings and wiring (control stat and high limit humidistat).

Check door interlock.

Unit turned ON. Contactor pulled

in, but no water is entering the

cylinder.

Check external shutoff valves and open if closed.

Check strainer and fill valve for clogs. Turn adjusting screw.

Check fill valve coil to determine if it is receiving 24 VAC. If so, replace the valve.

Check for break in wiring.

Excessive arcing in cylinder

Check drain valve and ensure that when it activates it drains freely. Clean if necessary.

Replace valve if defective.

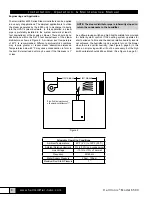

Check water supply. If it is softened, increase the Low Drain Threshold Pot (POT 2) up to

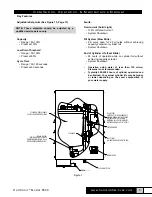

XX%. (See Figure 13.)

Use high conductivity settings if water supply is very hard, >750 micromho.

Unit filling slower or at the same rate as the water is boiling, causing over concentration and

foaming. Check restriction in fill line. Adjust the metering fill valve to allow greater flow of

water. (See Figure 11.)

Have water analyzed. If iron content is greater than .1 mg/liter, a filter will have to be used.

Consult factory with water analysis.

Unit fills to the cylinder full condition

and remains cold

Check between Test Point #3 and ground with a multimeter set on VDC scale. Confirm the

circuit board is seeing low current flow (<3.5 VDC). Proceed to next step.

If on initial fill, unit reaches less than 70% of rated capacity (3.5 VDC on Test Point #3), adjust

the drain threshold pot, POT 2, down 2-3%. Manually drain the unit down completely and add

½ Alka Seltzer tablet via the fill tee (GT-120). Restart the unit while monitoring the amp draw.

Fill unit ¼ full and turn “off” for several minutes to allow tablets to dissolve. Restart unit. If

amperage rises rapidly, it may be necessary to dilute the water. If amperage rises slowly, add

another Alka-Seltzer tablet.

Check that drain valve is sealing properly.

Check the water conductivity and consult the factory.

Unit turned ON and cycles for a

short period of time. Then it stops

in the middle of a fill cycle and will

not reset until boiling stops.

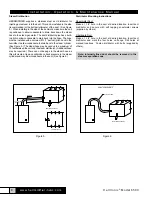

Check cylinder fill interface connections.

Check cylinder connections. (See Figure 12B.)

Check items in next troubleshooting tip concerning foaming.

Check amperage between cylinder full electrode and cylinder full interface terminal #1. If it is

greater than 7.0 mA AC, take a fill water sample and consult the factory.