I n s t a l l a t i o n , O p e r a t i o n , & M a i n t e n a n c e M a n u a l

4

www.herrmidifier-hvac.com

Herrtronic

®

Model 6500

SECTION II UNIT OPERATION

Basic Operation Overview

Controlled humidification requires a very precise control

system. The Herrtronic 6500 utilizes a microprocessor

based control system to monitor performance and maintain

capacity. The humidifier evaluates the operation and alerts

the operator to problem conditions and prevents undesirable

operation. (Refer to points on table below.)

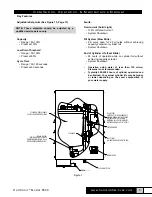

1.

On initial start-up or a call for humidity, the humidifier will

attempt to fill to its full load amp rating. The unit will not

necessarily have a full cylinder of water when capacity is

reached. Water level depends on the conductivity of the

water. The more conductive the water, the more current

that can be passed through and will result in a lower water

level during operation. If the water is not conductive enough

to allow the unit to reach full load amps (full capacity) on

the initial fill, the cylinder full module will stop the fill valve

until the water conductivity increases. The unit will operate

in this mode with repetitive fill and boil cycles until the

unit has concentrated enough minerals in the water to

reach the rated amp level. Once full load amp (FLA) has

been reached, the fill valve will shut off. The unit will now

compare the rate of change of amp draw to a time cycle.

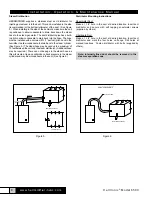

2. Once the water in the cylinder is mineral laden and hence

very conductive, a drain cycle will be initiated. Some or

all of the water in the cylinder will be drained to flush away

the minerals. After the drain cycle and/or the time cycle is

completed, the unit will refill and start the process over.

These cycles will repeat until:

•

The call for humidity is satisfied.

• The cylinder is used up.

• A fault condition occurs.

3.

Over a very long time, as the electrodes in the cylinder are

coated with minerals, the water level will slowly increase

to the cylinder full level. Concentration will no longer allow

the unit to reach FLA. The unit will eventually display an

“end of cylinder life” fault by blinking the LED on the front

of the unit at ½ second intervals. Replacement of the

cylinder is required at this point in order for the unit to

continue operating at its rated capacity.

Part No.

Qty.

Description

267460-001

1

Herrtronic 6500-1

267460-002

Herrtronic 6500-2

265160-001

1

Humidistat

265160-001

1

Humidistat (Use as High Limit)

AH-297

1

Air Proving Switch

EST-1138

2

Screw, Lag 5/16 x 2” Long

EST-1563

2

Clamp, Hose, 3/4” - 1 1/2”

EST-206

12”

Tubing, Clear PVC Vinyl, 1” OD

EST-207

1

Clamp, Hose SST

267949-001

1

Installation & Operation Manual

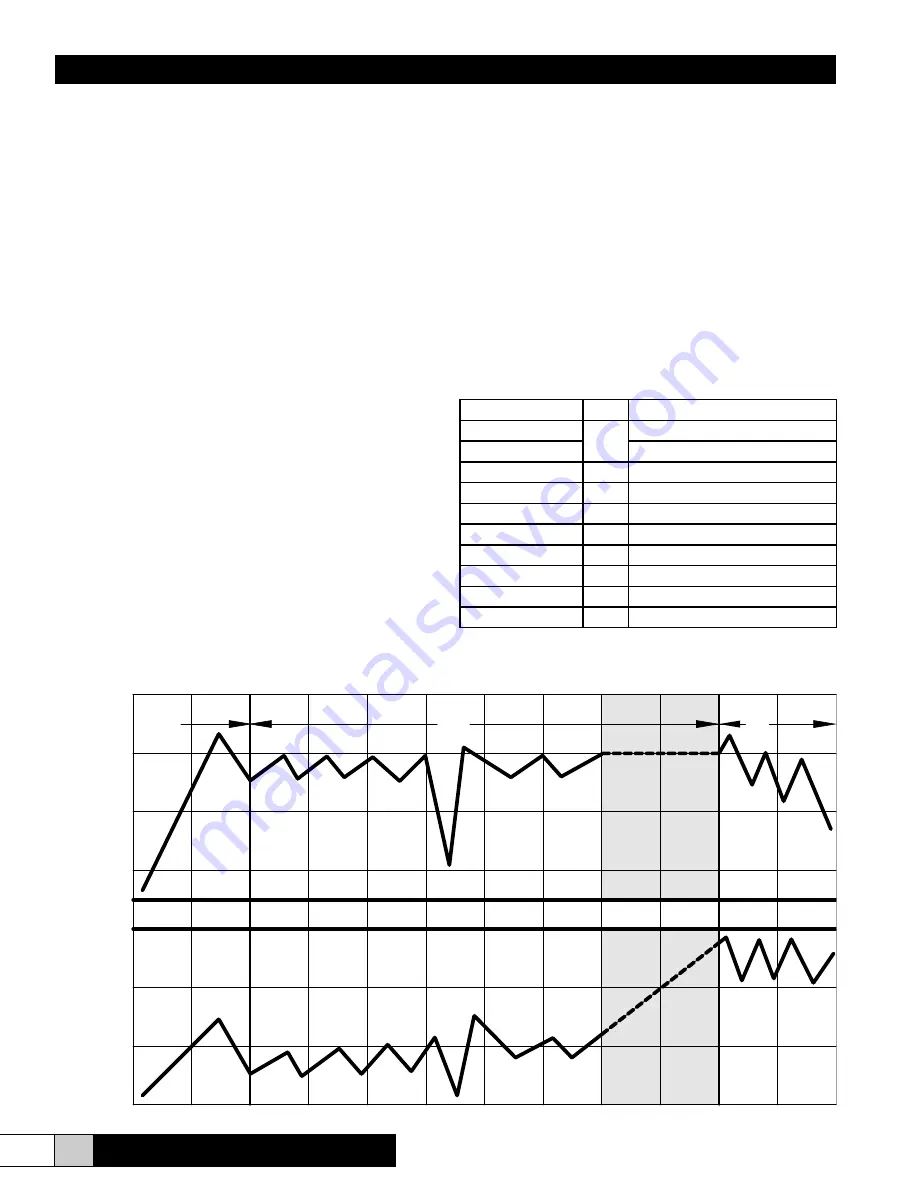

General Time of Operation

1.

2.

3.

High Drain

Threshold

Capacity

Set Point

Low Drain

Threshold

Cylinder

Full

Steadily Increase

Water Level

W

at

er L

ev

el

Output