I n s t a l l a t i o n , O p e r a t i o n , & M a i n t e n a n c e M a n u a l

7

www.herrmidifier-hvac.com

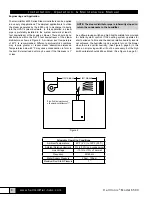

Plumbing

To make the necessary connections for water fill and drain, the

following steps are required. (Refer to Figure 4 for locations)

1. Install external shutoff valve between the water supply and

the humidifier for ease in servicing the unit.

2.

Connect water supply to the 1/4” compression fitting on the

bottom of the cabinet.

3. Connect the 3/4” tube from the accessory pack to the drain

reservoir. Cut the tube to the length necessary to reach the

drain.

4. Insert the other end of the tube into a minimum 6” vertical

length of the 1-1/4” minimum I.D. drain line. The balance of

the drain line should be 1” I.D. minimum with a minimum

1/8” per foot slope. (See Figure 4.)

SECTION III INSTALLATION INSTRUCTIONS

Mounting

The cabinet is designed to safely contain the working components

of the HERRMIDIFIER 6500 series humidifier and dissipate

heat to protect the electronics. Locate humidifier, steam pipe

and accessories in a manner to allow routine inspection and any

necessary maintenance. DO NOT install the unit above false

ceilings or around valuable property, where a malfunction could

cause damage. Correct positioning of the humidifier is important

to allow for proper operation and easy maintenance. Minimum

clearance around the cabinet should be maintained as follows:

Minimum Clearances

Around Cabinet

Left

6”

Right

12”

Top

6”

Bottom

12”

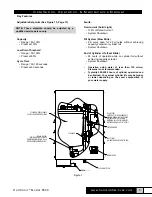

1. Remove cover by removing four side screws.

2. Remove foam packing from top of cylinder.

3. Two 5/16” lag bolts are supplied with the CFS20/22 unit.

Install the lag bolts according to the dimensions in Figure 3.

4. Hang the unit on the wall and secure the bolts. Be sure the

unit is level and mounted directly to the wall into wood studs

at least 2” thick (or equivalent). Operating weight is 27 lbs.

5. Replace cover and four screws.

Figure 3 (Back View)

WARNING!

Do not mount any controls inside the unit or tap power

from any location in the unit, except as stated in these

instructions. Do not place objects near the cabinet. Do

not attach to dry wall without studs. At least one of the

5/16” bolts must be located on a stud.

FIGURE #3

(BACK VIEW)

9.00

.91

1.31

Ø .625 X .313"

KEYHOLE MTG. SLOT

TYP. 2

CAUTION!

Do not use reverse osmosis or demineralized water

treatment without first consulting the factory. This

water may not be sufficiently conductive to allow proper

operation. Consult factory if water is outside the range

of allowable conductivities (125-1250 micro-Siemens).

Do not use hot water.

Herrtronic

®

Model 6500

WARNING!

If the drain line is exposed, it is recommended that it be

insulated for safety. Do not use PVC drain line unless

“Drain Tempering” is enabled.

NOTE: Inlet water pressure must be in the range of

20-100 psig. Consult the factory if you are outside this

range. Softened water may be used but requires that

the low drain threshold be adjusted.

DRAIN LINE TO BE 1" MIN. I.D. TERMINATING

AT THE UNIT WITH 6" OF 1 1/4" I.D. VERTICAL

PLUMBING.

THIS ALLOWS AN AIR GAP BETWEEN THE 1" O.D.

DRAIN TUBE FROM THE UNIT AND THE DRAIN.

1/4" O.D. COPPER OR

POLY TUBE WATER FILL LINE

3/4" MIN. I.D./1" MAX O.D.

FLEXIBLE DRAIN CONNECTION

6" MIN. LENGTH OF 1-1/4" MIN. I.D.

COPPER LINE. IF PVC IS USED OR LOCAL

CODES REQUIRE A LOWER TEMPERATURE

BALANCE OF DRAIN LINE TO BE 1" MIN. I.D.

WITH A MINIMUM PITCH OF 1/8" PER 12" OF RUN

DRAIN RESEVOIR

DRAIN WATER, ENABLE DRAIN TEMPERING.

4" RECOMMENDED

8"

RECOMMENDED

Figure 4