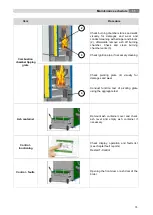

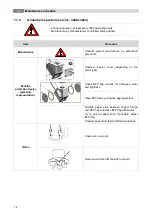

Fault reports and their corrections

10

71

No. Fault report

Cause of fault

Fault correction

088

BACK FLOW SET PWM

CAN communication to the PWM-

module was interrupted or the

module was not found

Check module CAN connection

Check module

✆

- contracting party

090

COMBUSTION

CHAMBER DOOR

Burning chamber door end switch

active; burning chamber door is

open

Close burning chamber door

091

WARNING ASH

DISCHARGE

Ash discharge has not cleaned or is

not rotating

Ash container full

Foreign matter is blocking the screw

Motor defective

Ash container empty

Remove debris

092

ERROR ASH

DISCHARGE

Ash removal could not be carried

out 3 times

Ash container full

Foreign matter is blocking the screw

Motor defective

Ash container empty

Remove debris

093

ENDSWITCH ROOM

DISCHARGE

Digital input Room discharge

system end switch active

Check discharge system (screw, ... )

to debris / blockage

095

CHECK ASH BOX

Set up ash container maintenance

interval exceeded

Check ash container

096

BURNER STOP

Digital input burner stop has

responded

Boiler is in the state "Boiler Stop"

contact open

097

Backup config

Fault when loading backup

✆

- contracting party

104

Boiler spreading

Boiler spread too low at nominal

load (less than 8K)

Reduce pump speed (step) to get

more spread

125

EXT.POWER MAX

The signal for external power

limitation has fallen below 1.3V

used CAN-ID (station number) must

not be used

adapt signal

✆

- contracting party

129

Suction turbine-HOURS

max. pellet sucker operating hours

have been exceeded

execute maintenance

check pellet sucker

130

ignition fan - hours

max. ignition fan operating hours

have been exceeded

execute maintenance

Check ignition fan

138

Suction hopper

CAN communication to the suction

container module was interrupted or

the module was not found

Check module CANBus connection

Check module

✆

- contracting party

139

Door Storage room

Digital input storage room door has

responded

Close storage room door

140

MP EXT. AS

Digital input motor protection

discharge has responded

motor protection acknowledge

Check discharge system (motor,

screw,...)

Remove debris

141

ES EXT.AS

Digital input end switch discharge

screw has responded

Check discharge system (motor,

screw,...)

Remove debris

142

point suction system

CAN communication to the point

suction module was interrupted or

the module was not found

Check module CANBus connection

Check module

✆

- contracting party

143

Position sensor

Error at position sensor / motor:

▪

Motor defective

▪

Position switch adjust / defective

check position switch or renew

check motor or renew

Summary of Contents for firematic CONDENSATION 30

Page 1: ...OPERATING INSTRUCTIONS Wood chips pellets heating system firematic CONDENSATION 30 40 ...

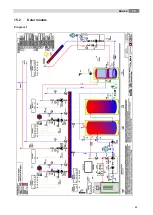

Page 83: ...Annex 15 83 15 ANNEX 15 1 Additional boiler module Hydraulic recommendation 1 ...

Page 84: ...15 Annex 84 Hydraulic recommendation 2 ...

Page 85: ...Annex 15 85 15 2 Solar module Program 1 ...

Page 86: ...15 Annex 86 Program 2 ...

Page 87: ...Annex 15 87 Program 3 ...

Page 88: ...15 Annex 88 Program 4 ...

Page 89: ...Annex 15 89 Program 5 ...

Page 90: ...15 Annex 90 Program 6 ...

Page 91: ...Notes 16 91 16 NOTES ...