Fault reports and their corrections

10

73

10.1

Not indicated faults

Fault

Cause of fault

Fault correction

Boiler output

gradually decreases

Ash/slag on the grate; fly ash container is

full; heat exchanger heavily clogged /

sooted; inferior quality fuel

Reduce cleaning intervals or clean

manually; empty the fly ash container;

clean heat exchanger.

Desired operating

temperature is not

reached.

Inferior quality fuel;

previous boiler output higher than current

boiler output;

fuel level too low

Replace fuel if necessary, install larger

boiler; increase fuel level

Ash outlet at the

chimney and

connection pipe

Fly ash container full; fuel contains of

excessive finds or super fines; fan speed

too high; chimney draught to high; Ash

outlet at the chimney connection pipe

Remove fly ash; replace fuel if

necessary or retrofit flue gas deduster;

reduce speeds; retrofit chimney draught

regulator;

Deflagrations

Fuel to dry

Fuel to fine

Use fuel according to specifications

soot fire

In the stainless steel connecting line

seals (soot fire) must be check and

replace the seals after a fault!

Flue gas outlet on

the boiler or exhaust

pipe

•

Incorrect layout / double occupancy of

the chimney

•

Leaks (defective seals on doors, ash

box, exhaust pipe ...)

•

Maintenance interval exceeded, soot

build-up, soiling, sooting in the boiler or

exhaust pipe

•

Burning chamber door opened

•

Unfavourable draft conditions, lack of

air, low delivery pressure;

•

Deflagration, unsuitable fuel

•

Design of the chimney according to

the specifications of the assembly /

installation instructions

•

Check seals and have defective /

damaged ones replaced by a

specialist.

•

Perform maintenance, clean boiler or

flue gas line.

•

Only open the combustion chamber

door in the cases recommended

according to the instructions.

•

Check air regulation

•

Use fuel according to specifications

Flue gas outlet on

the boiler or exhaust

pipe

automatically loaded

system

•

Too much fuel in the combustion

chamber

•

Check and adjust timing of the slide

Summary of Contents for firematic CONDENSATION 30

Page 1: ...OPERATING INSTRUCTIONS Wood chips pellets heating system firematic CONDENSATION 30 40 ...

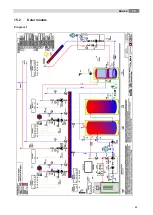

Page 83: ...Annex 15 83 15 ANNEX 15 1 Additional boiler module Hydraulic recommendation 1 ...

Page 84: ...15 Annex 84 Hydraulic recommendation 2 ...

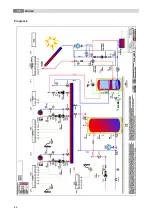

Page 85: ...Annex 15 85 15 2 Solar module Program 1 ...

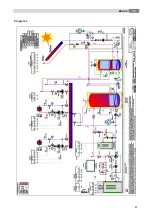

Page 86: ...15 Annex 86 Program 2 ...

Page 87: ...Annex 15 87 Program 3 ...

Page 88: ...15 Annex 88 Program 4 ...

Page 89: ...Annex 15 89 Program 5 ...

Page 90: ...15 Annex 90 Program 6 ...

Page 91: ...Notes 16 91 16 NOTES ...