10

Maintenance schedule (Customer inspection)

82

Item

Procedure

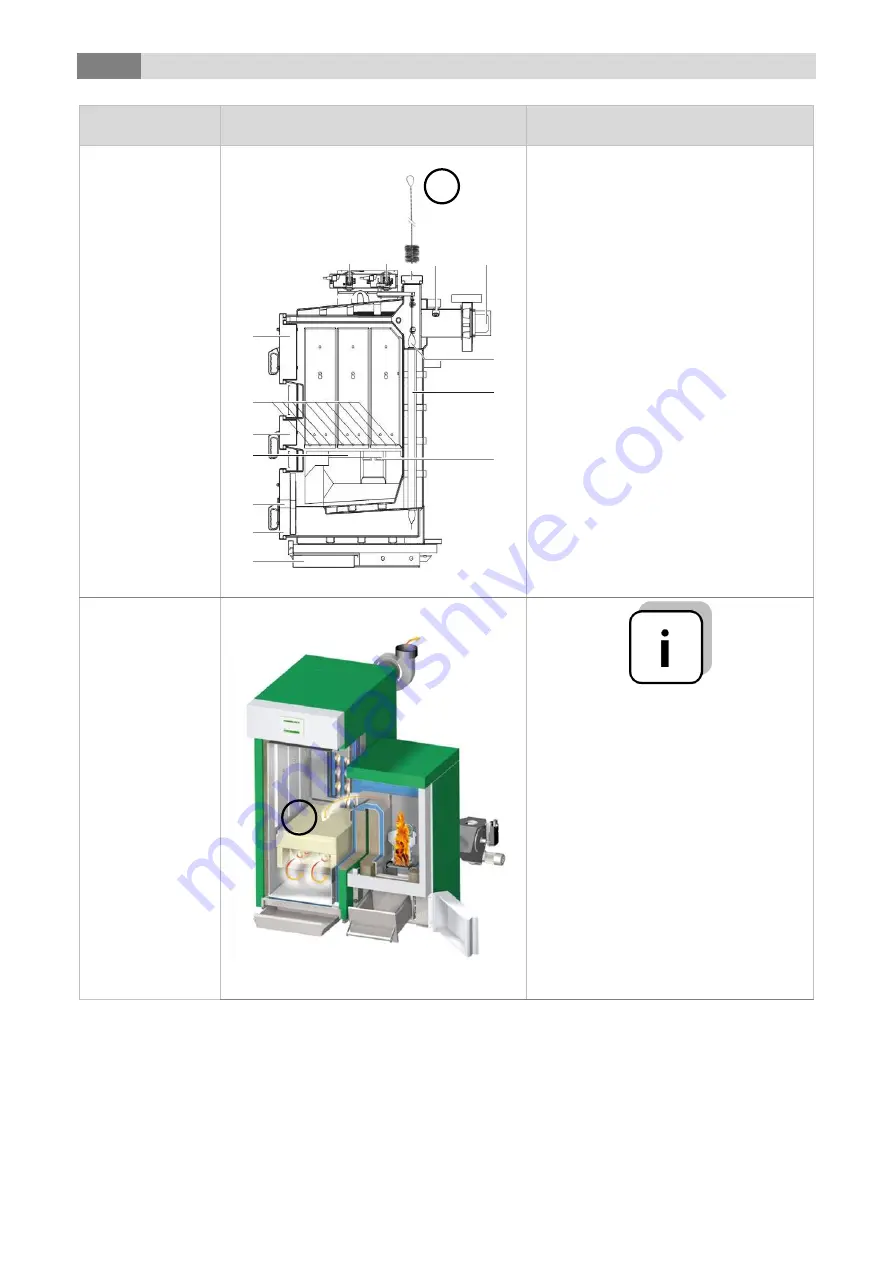

Heat exchanger

Clean the heat exchange pipes with the

boiler brushes. Here the ventilator can

also be switched on in order to suck

away any dust forming in the air. This

can simply be carried out in the Unit Off

condition in the so-called aggregate

test.(Parameter A04

– ID Fan)

After cleaning

Set the turbulators correctly again,

Put on the cleaning cover, tighten the

closing screws and

Install the boiler casing

The accumulated ash should be removed

via the ash door.

Conduct function test of heat exchanger

using the aggregate test

Remove deposit and check heat

exchanger visually for damages and

wear.

Burning chamber

Expansion cracks at insulating plates,

respectively burning chamber stones,

don´t affect their capacities and don´t

represent warranty claim.

During cleaning ensure that the slot

between the burner plates is not clogged

(see picture below). On the burner plates

themselves, an ash layer of about 5 cm

can be left which is provided for glow

sustainment.

Attention:

The combustion chamber must always

be cleaned last, as the ash may fall in the

burn-off areas when cleaning the heat

exchanger pipes.

Check ignition pipe, if necessary cleaning

6

5

Summary of Contents for pelletfire 20/20

Page 1: ...OPERATING INSTRUCTIONS Log wood pellet heating system pelletfire 20 40 ...

Page 90: ...15 Annex 90 15 ANNEX 15 1 Additional boiler module Hydraulic recommendation 1 ...

Page 91: ...Annex 15 91 Hydraulic recommendation 2 ...

Page 92: ...15 Annex 92 15 2 Solar module Program 1 ...

Page 93: ...Annex 15 93 Program 2 ...

Page 94: ...15 Annex 94 Program 3 ...

Page 95: ...Annex 15 95 Program 4 ...

Page 96: ...15 Annex 96 Program 5 ...

Page 97: ...Annex 15 97 Program 6 ...

Page 98: ...16 Notes 98 16 NOTES ...

Page 99: ...Notes 16 99 ...