12

Fault reports and their correction

74

Betriebsanleitung_pelletfire_Touch_Englisch_V1.2

Nr. Fault text

Reason

Suggestions for rectifying

065

CONTACTS BFP

Fault of the BFP contacts (both

End-switches are closed at the

same time)

✆

- contracting party

Carry out check BFP by specialist

personnel

066

IGNITION

Heat supplier didn´t ignite fuel within

15 minutes

Check fuel level

Check burning parameters, adjust

as necessary

Check fuel level at firing

067

FIRE OUT

Flame monitoring device indicates

no burning

Check fuel level

Check burning parameters, adjust

as necessary

Clean intermediate hopper level

sensor

068

TEMP. CONTROL

Temperature monitoring in the

storage room has risen above the

maximum permissible temperature.

Sensor in the storage room has

risen above the permissible range

Check boiler system

If fire, alarm fire brigade

069

STL

Boiler temperature has exceeded

the permissible maximum

temperature

Cool down boiler (< 75 °C)

Quit STL

071

LAMBDA FUEL

Lambda probe calibration error

✆

- contracting party

072

CAN FAULT

Fault in CAN Bus

✆

- contracting party

073

LAMBDA CALIBRATION

Failure when calibrate the lambda

probe

✆

- contracting party

076

FUEL

Error „fire out“(067) has occured

within 2h again

Check fuel level

Check burning parameters, adjust

as necessary

Clean intermediate hopper level

sensor

077

ADDITIONAL INPUT

Additional input (for example CO

detector) has been activated.

Check failure at additional input

aggregate

078

NIVEAU LEVEL

Active intermediate hopper level

sensor; low fuel level at

intermediate hopper

Check fuel level

Check discharge system (motor,

screw, springs)

079

BARRIER LEVEL

Active feeding screw channel

sensor; low fuel level in feeding

system

Check fuel level

Check discharge system (motor,

screw, springs)

080

MP ROOM DISCHARGE

Active discharge screw motor

protection

Check discharge system (motor,

screw, springs) to debris

081

SPEED ID-FAN

Fault in the device for monitoring

the speed of the induced-draught

fan

Check connection rotation speed

sensor

Check ID-fan

✆

- contracting party

082

GRATE CLEANING 1

Fault affecting grate cleaning

• Limit switch is always in the same

position

• Drive motor for grate cleaning

defective

• Drive linkage defective or loose

Combustion grate sensor out of

position

Check grate cleaning motor

Check grate linkage

Check grate cleaning end switch

✆

- contracting party

Summary of Contents for pelletfire

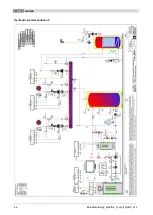

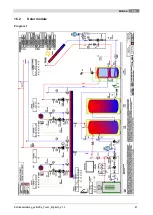

Page 1: ...Operating instructions Log Wood Pellet heatingsystem pelletfire 20 40 ...

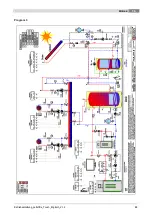

Page 86: ...16 Annex 86 Betriebsanleitung_pelletfire_Touch_Englisch_V1 2 Hydraulic recommendation 2 ...

Page 87: ...Annex 16 Betriebsanleitung_pelletfire_Touch_Englisch_V1 2 87 16 2 Solar module Program 1 ...

Page 88: ...16 Annex 88 Betriebsanleitung_pelletfire_Touch_Englisch_V1 2 Program 2 ...

Page 89: ...Annex 16 Betriebsanleitung_pelletfire_Touch_Englisch_V1 2 89 Program 3 ...

Page 90: ...16 Annex 90 Betriebsanleitung_pelletfire_Touch_Englisch_V1 2 Program 4 ...

Page 91: ...Annex 16 Betriebsanleitung_pelletfire_Touch_Englisch_V1 2 91 Program 5 ...

Page 92: ...16 Annex 92 Betriebsanleitung_pelletfire_Touch_Englisch_V1 2 Program 6 ...

Page 93: ...Notes 17 Betriebsanleitung_pelletfire_Touch_Englisch_V1 2 93 17 NOTES ...

Page 94: ...17 Notes 94 Betriebsanleitung_pelletfire_Touch_Englisch_V1 2 ...

Page 95: ...Notes 17 Betriebsanleitung_pelletfire_Touch_Englisch_V1 2 95 ...