13

Maintenance schedule (Customer inspection)

82

Betriebsanleitung_pelletfire_Touch_Englisch_V1.2

Equipment area

Action

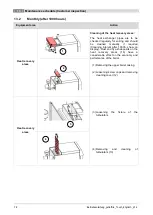

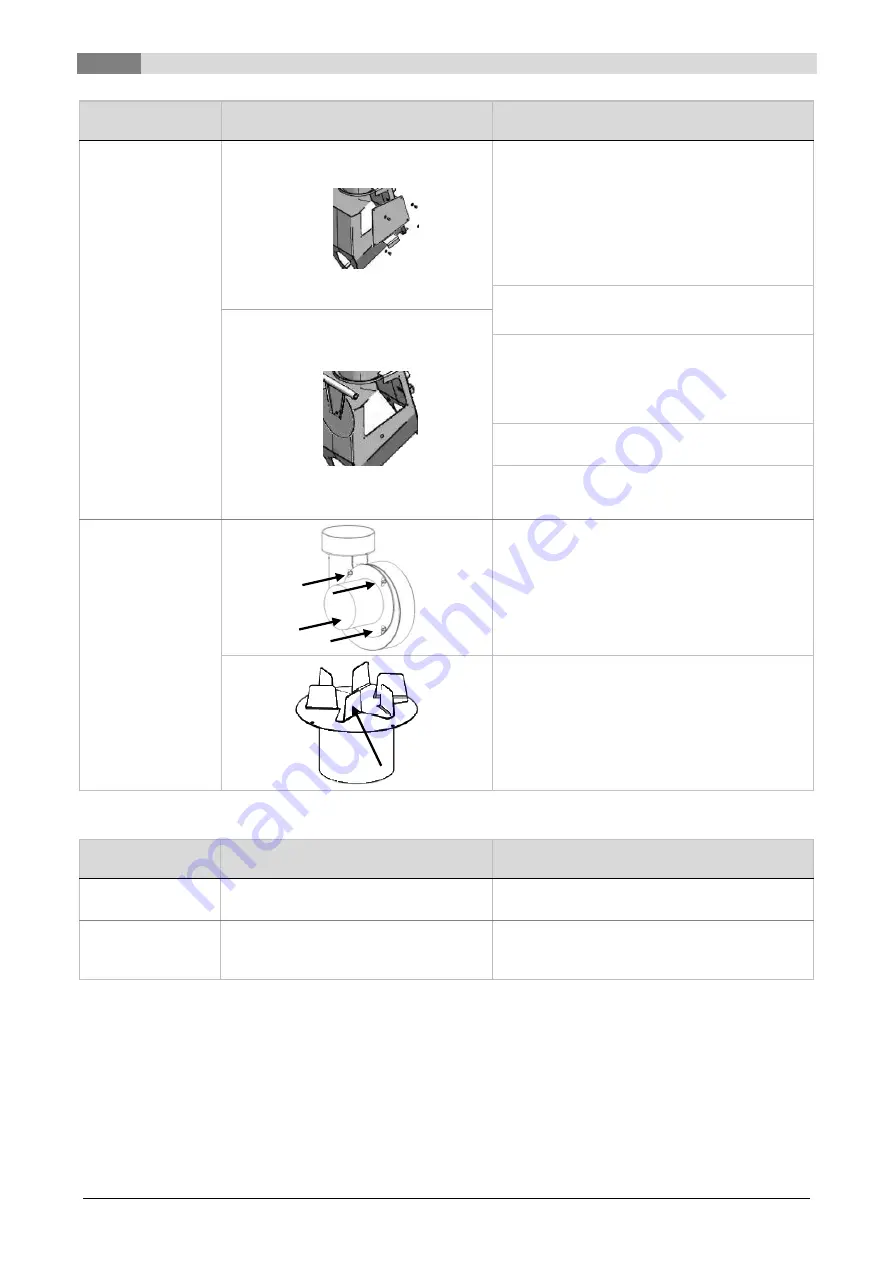

Flange bearing

(Pellet burner)

Unscrew revision cover

Check BFP flap visually for damages, wear

and tightness

Open BFP flap by using the aggregate test.

Position paper strip between hopper flange

and BFP flap and close BFP flap afterwards.

Try to pull out paper strip. If possible, adjust

BFP flap.

Conduct paper strip test at different positions.

ID-fan

Unscrew 4x wing nut

Remove and clean ID-fan witch a brush.

13.4

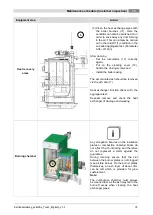

If required

Equipment area

Action

Chimney

Maintenance

respectively

Cleaning

and

inspection according to national standards

Fuel storage

room

Fuel storage room emptying (at least after 3

fillings) and check visually for damages and

wear (e.g.: stones, damaged walls,...)

Summary of Contents for pelletfire

Page 1: ...Operating instructions Log Wood Pellet heatingsystem pelletfire 20 40 ...

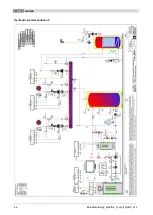

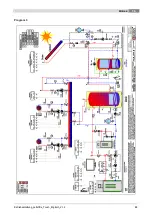

Page 86: ...16 Annex 86 Betriebsanleitung_pelletfire_Touch_Englisch_V1 2 Hydraulic recommendation 2 ...

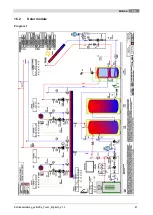

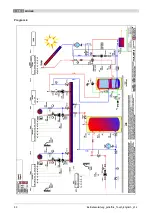

Page 87: ...Annex 16 Betriebsanleitung_pelletfire_Touch_Englisch_V1 2 87 16 2 Solar module Program 1 ...

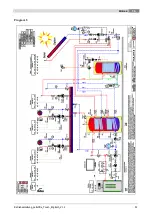

Page 88: ...16 Annex 88 Betriebsanleitung_pelletfire_Touch_Englisch_V1 2 Program 2 ...

Page 89: ...Annex 16 Betriebsanleitung_pelletfire_Touch_Englisch_V1 2 89 Program 3 ...

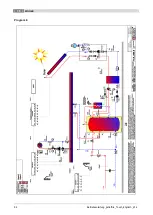

Page 90: ...16 Annex 90 Betriebsanleitung_pelletfire_Touch_Englisch_V1 2 Program 4 ...

Page 91: ...Annex 16 Betriebsanleitung_pelletfire_Touch_Englisch_V1 2 91 Program 5 ...

Page 92: ...16 Annex 92 Betriebsanleitung_pelletfire_Touch_Englisch_V1 2 Program 6 ...

Page 93: ...Notes 17 Betriebsanleitung_pelletfire_Touch_Englisch_V1 2 93 17 NOTES ...

Page 94: ...17 Notes 94 Betriebsanleitung_pelletfire_Touch_Englisch_V1 2 ...

Page 95: ...Notes 17 Betriebsanleitung_pelletfire_Touch_Englisch_V1 2 95 ...