3

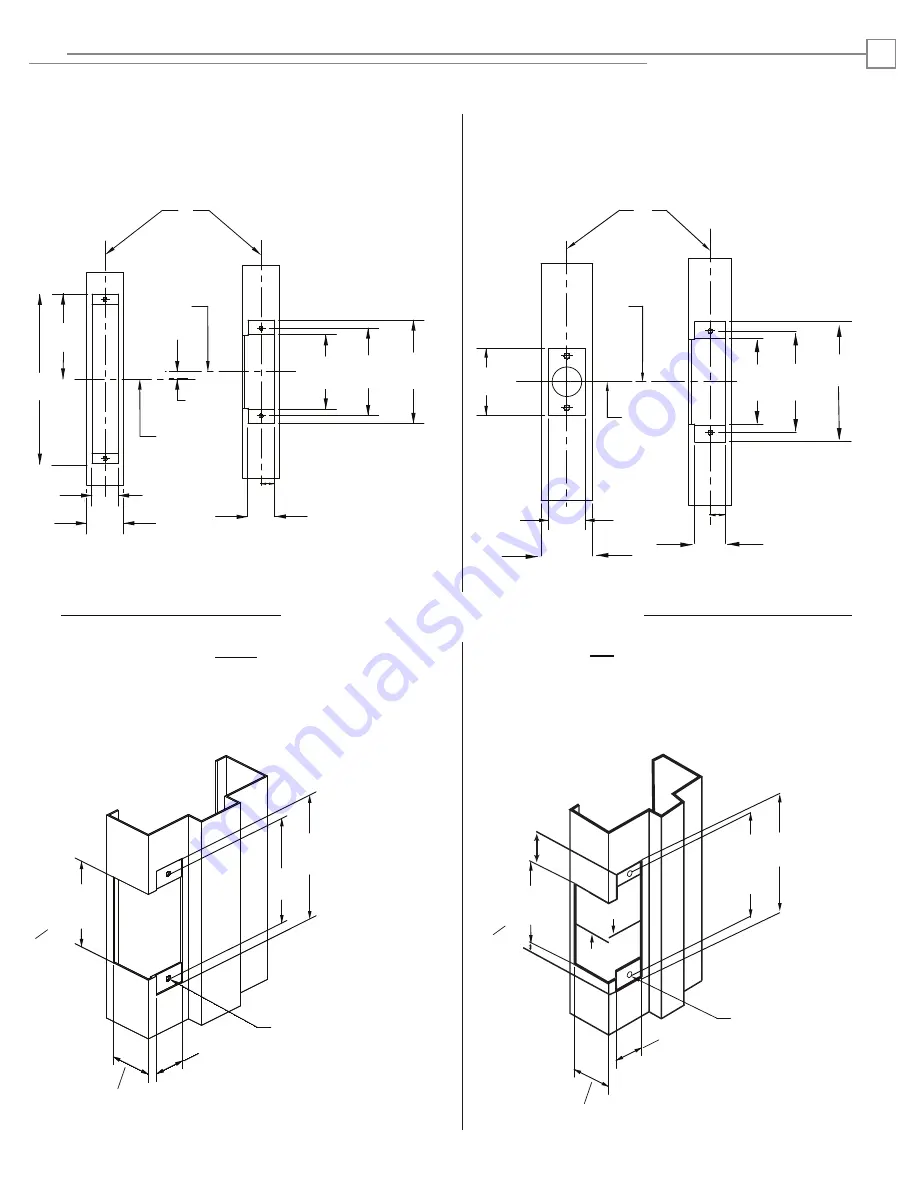

METAL JAMB DIMENSIONS FOR FACEPLATES

2 X 12-24

UNC THREADS

2 X 12-24

UNC THREADS

1-1/4"

1

-1/4"

5/32”

4-7/8"

[123.83 mm]

4-1/8"

[104.77 mm]

[85.72 mm]

3-3/8"

[31.8 mm]

[85.72 mm]

3-3/8"

[31.8 mm]

4-1/8"

[104.77 mm]

4-7/8"

[123.83 mm]

CL

CL

29/32”

[23.01 mm]

19/32”

[15.08 mm]

Normally Used With Mortise Locks Without Deadbolt

NOTE1:

Cannot be used with Schlage L9000 or Yale 8700 series.

NOTE2: Add 1/4” [6 mm] to this dimension when using a lip extension.

Cutout dimenstions for option faceplates (metal jamb): 1J, 1KM, 1NM

Normally Used With Mortise Locks With Deadbolt

NOTE1:

Can be used with Schlage L9000 or Yale 8700 series.

NOTE2: Add 1/4” [6 mm] to this dimension when using a lip extension.

Cutout dimenstions for option faceplates (metal jamb): 1KD, 1ND, 1NTD

Inches [mm]

CYLINDRICAL LOCKSETS

MORTISE LOCKSETS

Inches [mm]

CL

Strike

Prep

3/8"

*

4"

8"

1-1/4"

1-3/4"

Vertical

Centerline

CL

Lock

4-7/8"

4-1/8"

3-1/2"

5/8"

1-1/4"

Mortise

Lockset

CL

Strike

CL

Strike

Prep

5/8"

1-1/4"

Cylindrical

Lock

CL

CL

STRIKE

LOCK

Vertical

Centerline

2-1/4"

1-1/4"

1-3/4"

Please note the horizontal centerline of the electric strike in relation to

the centerline of the mortise lockset.

Please note the horizontal centerline of the electric strike in relation to

the centerline of the cylindrical lockset.

[203.2 mm]

[101.6 mm]

[44.45 mm]

[31.8 mm]

[9.53 mm]

[15.88 mm]

[31.8 mm]

[88.9 mm] [104.77 mm] [123.83 mm]

[57.15 mm]

[31.8 mm]

[44.45 mm]

[15.88 mm]

[31.8 mm]

3-1/2"

[88.9 mm]

4-1/8"

[104.77 mm]

4-7/8"

[123.83 mm]

Preparing the Frame

1500 – 1-1/8” [28.58 mm]

1600 – 1-3/8” [34.93 mm]

1500 – 1-1/8” [28.58 mm]

1600 – 1-3/8” [34.93 mm]

*

Can be Mortise lock and option specific. See figures below if

using a Schlage L9000 or Yale 8700 series.

Inches [mm]

Inches [mm]

See Note 2

See Note 2

NOTE3: Add 3/8” [9.5 mm] to this dimension when using a lip extension.

NOTE3: Add 3/8” [9.5 mm] to this dimension when using a lip extension.

See Note 3

}

}

See Note 3

3086006.001 Rev 3

Please see Notes 2 & 3 for dimensions when using Lip Extensions

*

**

*

**

*

**

*

**