Part Number 3085006.001, Rev. A

2

SYSTEM OVERVIEW

The K200-622 wired cabinet lock (K200) extends access control to a cabinet or drawer. The K200 lock is capable

of reading radio-frequency identification (RFID) credentials and providing that credential data to an electronic

access control (EAC) system via Wiegand data signaling. The EAC is responsible for determining whether user

access should be granted or denied. When the EAC provides an active-high unlock signal to the lock in the access

granted case, the K200 drives a motor to complete the unlock/lock cycle. EAC indication of user access/denial is

provided to the user by way of LED control inputs on each lock. Additional lock monitoring features (e.g., door

position, tamper) are monitored within the lock and status of each is provided to the EAC.

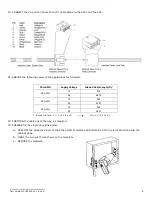

External Interface Signals Summary:

Lock Signal

Name

Lock Signal

Direction and Wire

Color

Electrical Interface

Logic

Vin

Input,

Red/24 AWG

Power to Reader

Input Power

Unlock

Input,

Orange/24 AWG

Wetted Relay Contact

Closure

(0–35 VDC)

Active High

Tamper / Door

Po

Output,

Yellow/24 AWG

Dry Contact

(0–35 VDC, <100mA)

Open = Unlocked

Closed = Locked

Tamper / Door

Position –

Output,

Blue/24 AWG

Dry Contact

(0–35 VDC, <100mA)

Open = Unlocked

Closed = Locked

Wiegand Data 0

Output,

Green/24 AWG

0–5 VDC

Active Low

Wiegand Data 1

Output,

White/24 AWG

0–5 VDC

Active Low

Green LED

Input,

Brown/24 AWG

0–5 VDC

Active Low

Red LED

Input,

White/Brown/24 AWG 0–5 VDC

Active Low

Ground/Return

Input,

Black/24 AWG

– –

LED Function:

LED states are controlled and defined by the User’s EAC. Enabling the red and green LEDs on

the K200 occurs via an active low (ground) signal.

Output Type:

SIAAC-01-1996 Wiegand Output Compliant.

FCC Part 15, Compliant, Industry Canada Compliant

BHMA: A156.3, A156.36, A156.25 Compliant

Credentials Supported:

125kHz Proximity or 13.56MHz iCLASS, iCLASS SEOS, iCLASS SE, ISO 15693

ICLASS, ISO 14443A Mifare, Mifare Plus, Desfire SE, Desfire EV1, and NFC over HCE.