Installing the Wire Rope

• Ensure the wire rope spools correctly and is attached firmly to the winch drum to prevent release of the load.

• Wear protective clothing when working with the wire rope.

• Prevent damage to the rope by keeping it clean and not allowing it to pass through dirt or debris.

Consider the following information when choosing

the proper wire rope.

• Lay of the rope should match the winding direction of the drum.

• Breaking strength should be at least 3 times greater than the largest load when pulling on a horizontal

surface. 5 times that if loads are lifted or pulled at inclines.

• OZBLOK advises a 7 x 19 galvanized aircraft cable be used for diameters up to 5/16 inch.

• Contact a wire rope supplier for further assistance.

Installation

1. Use a flange clip or quick disconnect anchor to anchor the rope to the drum.

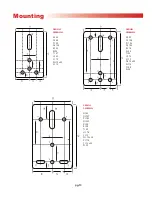

a. Flange Clip Anchor

i. Thread the end of the wire rope through the flange hole.

ii. Connect the carriage bolt and wrap the wire rope around it.

iii. Fit the clip on so that it holds the wire rope with its curves.

iv. Tighten the jam nut on until it flattens the wire rope against the drum flange.

b. Quick Disconnect Anchor

i. Insert the End Stop through the center hole in the drum flange.

ii. Pull the wire rope and the end stop into the slot.

2. Spool the rope onto the drum by turning the handle clockwise.

a. If the rope unwinds it needs to be re-installed correctly before continuing.

3. Keep the rope under tension, and using the winch, spool four full wraps of rope onto the drum.

pg.7

Drum End View

Drum End View