7

oPerational ProBleMs

The chimney must be swept at least once a year,

we recommend the use of a NACS (national as-

sociation of chimney sweeps) registered chim-

ney sweep. In the event of smoke or malodo-

rous fumes being produced, you must first

check to see whether the chimney is blocked.

The chimney must, of course, always provide

the minimum draught necessary to ensure that

it is possible to regulate the fire. Please note,

however, that chimney draft is dependent on the

weather conditions. In high winds, the draft can

become so powerful that it may be necessary

to fit a damper in the flue gas pipe to regulate

the draft. When cleaning the chimney, soot and

other deposits may come to fall on the smoke

turning plate. In cases where the wood burns

too quickly, this may be due to excessive chim-

ney draught. You should also check to make

sure that the door seal is intact and correctly

fitting.

If the stove it generating too little heat, this may

be because you are firing with wet wood. In this

case, much of the heating energy is used to dry

the wood, resulting in poor heating economics

and an increased risk of soot deposits in the

chimney.

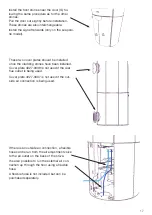

Check whether the air holes in the stones are

blocked with for example ashes etc. Below the

casted shaking grate is it possible to clean the

air channel for the start-up airflow.

MaintenanCe

The surface of the stove has been treated with

heat-resistant paint.

The stove should be cleaned with a damp cloth.

Any damage to the surface in the form of chips

or scratches can be repaired using touch-up

paint, which is available in spray cans.

Cleaning the glass

Incorrect firing, for example using wet wood,

can result in the viewing window becoming co-

vered in soot. This soot can be easily and effec-

tively removed by using proprietary stove glass

cleaner.

Cleaning and repairing

soapstone surfaces

Soapstone is a relatively soft natural product.

It is therefore possible to repair scratches or

other damage to the surface.

Cleaning soapstone surfaces

Clean soot, grease, etc. from surfaces using

water and soft soap or similar.

- Spread the soap on the surface

- Let it stand a few minutes

- Rinse off the surface using hot water

- Once the surface is dry you can sand it gently

if necessary using sandpaper (120 grit)

Minor scratches and impact marks

Gently sand using sandpaper (120 grit) until the

scratches are gone. It is a good idea to use a

sanding block. To maintain a uniform surface on

the stone, the entire surface should be gently

sanded at the end.

Chipped surfaces

This section covers more serious damage, such

as if a piece has chipped off or is missing. If the

chipped off piece is intact, it can be glued in

place using ’waterglass’ (available from Heta

A/S). Apply waterglass to the surfaces, clamp in

place for 24 hours, then sand using sandpaper

(120 grit). If a piece is missing or an impact mark

is deep, you can repair the damage using a mix

of soapstone powder and waterglass (available

from Heta A/S). Mix the powder and waterglass

to an appropriate consistency. Clean off any

dust before applying the mixture. Brush the sur-

face with waterglass to ensure good adhesion.

Apply the soapstone mixture generously, as it

contracts during hardening. Do a repeat appli-

cation if necessary. The hardened surface can

be sanded after 24 hours. Use 60-80 grit sand-

paper initially, and then 120 grit sandpaper to

finish.

Cleaning ceramic surfaces

The ceramics have a glazed surface and can be

wiped with a damp cloth.

Summary of Contents for SCAN-LINE 80

Page 14: ...14...