2

13

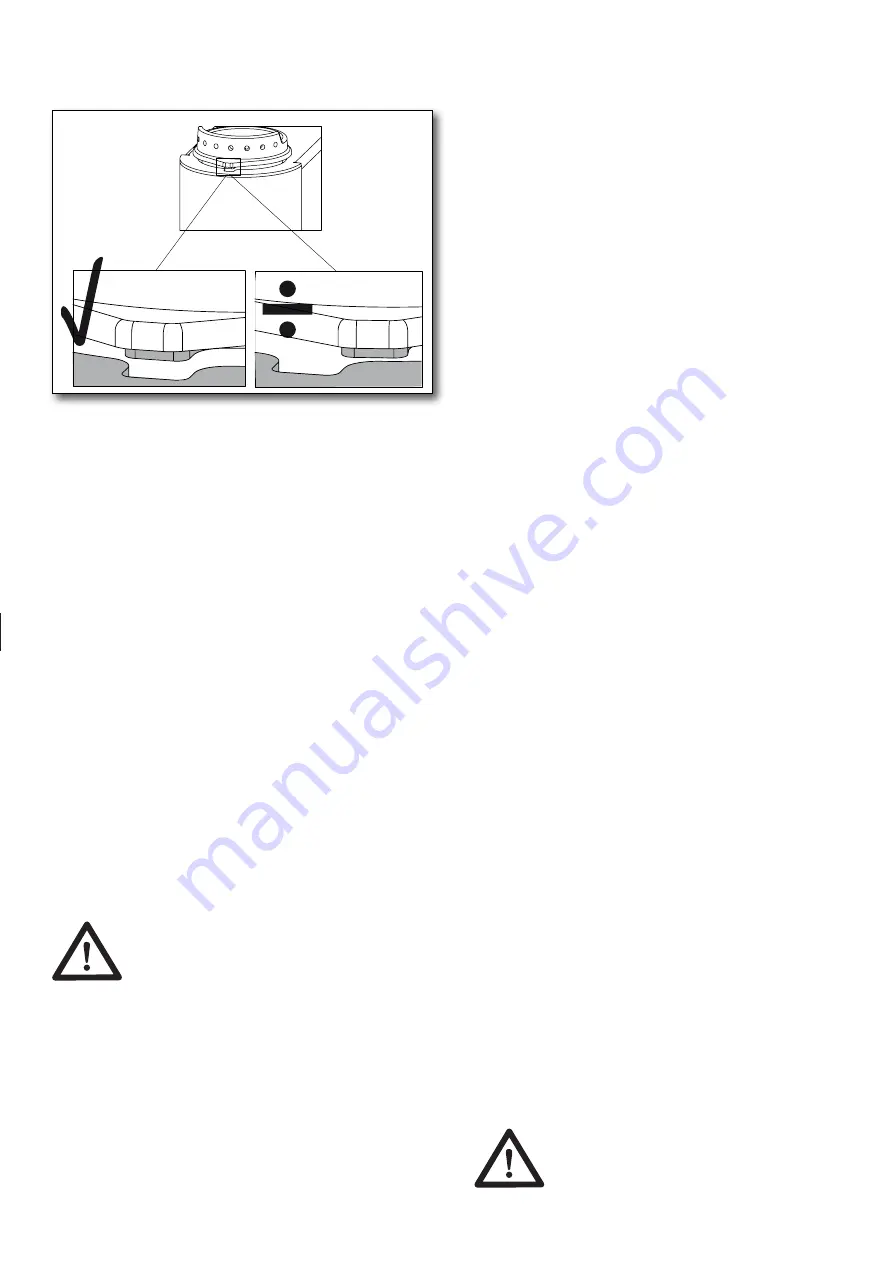

Inserting the burn pot after cleaning.

Fig. 2

Cleaning the glass

Clean the glass whenever necessary. Depen-

ding on the pellet quality and heat level used

(a low heat level leads to more dirt/deposits),

deposits will eventually form on the glass. The-

se can be removed using paper or a cloth and

glass cleaning agent.

Cleaning the display

The display can be cleaned gently using a dry

cloth. Grease stains are removed by drying the

unit with a cloth and a mild detergent.

Monthly cleaning

Emptying the combustion chamber

The combustion chamber must be vacuumed

approximately once a month depending on how

often the stove is in operation and the quality of

the pellets. The stove requires light but regular

cleaning to ensure stable operation.

Note: This is done when both the

stove and the ashes are cold.

Glass door seal and gaskets

It is important that the glass door seal, the ash

pan gasket and pellet tank cover seals tightly,

as the stove requires underpressure in the

combustion chamber for correct operation.

The glass seals must be replaced if worn, or

glued in place using ceramic glue if loose.

Ask your dealer if you need assistance.

Emptying/Cleaning of the pellet tank (*)

Pellettank should be emptied and vacuumed for

dust and pellet remains at least monthly.

Semi annually / Annually

Internal flue pipe and chimney fan (*)

The stove’s internal flue pipe must be kept free

from ash and soot. Clean the pipe with a clea-

ning brush and vacuum the ash room. Remove

the chimney fan and clean any ash or soot off

the housing and blades.

Cleaning the Pressostat: (*)

The pressostat is connected to the chimney fan

by a silicone hose. Clean the silicone hose if

dirty using water and soap (ensure it is complet-

ely dry before reinstalling). Apply suction to the

pressostat inlet and listen to hear if it clicks.

Cleaning the convection fan (*)

Check that the convection fan turns easily by

turning it with your fingers. Clean off dust and

any other dirt, for example using a soft brush.

Cleaning the flue gas channel (*)

Clean the flue with a cleaning brush. Vacuum

and clean any soot and ash from the inspection

hole, which is located behind the ash pan.

Items marked (*)

should only be made by an authorized dealer,

however, there may be special circumstances

that cause the frequency of cleaning these com-

ponents to be more frequent than indicated here

if the environment where the oven is installed re-

quires this. This can be done by the customer by

agreement.

Service interval

There is a built-in service counter.

The status of this SERVICE COUNTER can be

found in the information menu.

This SERVICE COUNTER counts down from

1,800 hours. An alarm will sound when this time

has expired. This alarm will continue to flash un-

til an authorised service technician has serviced

the stove and reset the service counter.

The stove can still be used in this period.

Service interval 1800 operating

hours or at least once a year.