52

Safety Inspection

1.

Check all thermostats and high limit settings.

2.

During the following safety checks leave manome-

ters hooked up, check and record.

3.

If other gas-fired appliances in the room are on the

same gas main, check all pressures on the Hi

Delta with all other equipment running.

4.

Check thermostats for ON-OFF operation.

5.

Check high limits for ON-OFF operation.

6.

While in operation, check flow switch operation.

7.

Check the low gas pressure switch. (For proper

adjustment, use the attached manometers, if

available, to set pressure. The scales on the

switch are approximate only.) Low gas pressure

switch must be set at 5.0 in. WC for natural gas

and 10.0 in. WC for propane gas.

8.

Make sure that the high gas pressure switch (op-

tional) is set to 1.0 in. WC above manifold pres-

sure.

Follow-Up

Safety checks must be recorded as performed.

Turn heater on. After main burner ignition:

1.

Check manometer for proper reading.

2.

Cycle heater several times and re-check readings.

3.

Remove all manometers and replace caps and

screws.

4.

Replace all gas pressure caps.

5.

Check for gas leaks one more time.

Pilot Turn-Down Test

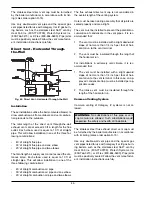

The Hi Delta heaters, depending on their size, have

one to three burner sections. Each burner section is

supplied gas by gas valves incorporated into a single

valve body. A maximum of three burner sections may

be controlled by a single hot surface ignition system.

The middle of the three burner sections is ignited

directly with a hot surface ignition system.

The burner section that is ignited directly by the hot

surface ignition system serves as a supervised pilot to

light the burner sections on either side of it. The burn-

er sections on either side of the supervised section

(pilot) are electrically interlocked with the supervised

ignition system so as they are not energized unless

flame is proven on the center section which is acting

as a pilot to light the right and left-hand sections.

The pilot turn-down test is conducted as follows:

1.

Turn off manual valves on non-supervised burner

sections.

2.

Turn on electrical power and adjust thermostat to

call for heat.

3.

Wait for completion of ignition sequence to light

burner section being utilized as a pilot for those

turned off in step 1 above.

4.

Gradually reduce manifold pressure (flame) on

supervised burner section by slowly closing man-

ual gas valve. Watch for shut-down due to loss of

supervised flame signal as pressure is being re-

duced. Flame signal should be lost before mani-

fold pressure goes below 2.0 in. WC for natural

gas and 6.0 in. WC for propane gas.

Leak Test Procedure: Dual-Seat Gas

Valves

Proper leak testing requires three pressure test points

in the gas train.

Test point A is upstream of the automatic gas valve. On

the first automatic valve, this is a bleedle valve. On the

other valves, this is a plugged port. The bleedle valve

on the first valve may be used for all the other valves

as well.

Test point B is a bleedle valve located between the two

automatic gas valve seats.

Test point C is located downstream of both automatic

gas valve seats and upstream of the manual valve. On

the manual valve, this is a bleedle valve. Identical

readings will be found at the plugged port labeled as

Alternate C.

Refer to Fig. 44. The numbers on the diagram refer to

the steps below:

These tests are to be conducted with the electrical

power to the heater turned off.