INSTRUCTION MANUAL – AIR DRIVEN HYDRAULIC PUMPS:

Model Series: AHP1120, AHP1120R, AHP1121, AHP1121R, AHP1122, AHP1122R, AHP1141, AHP1142,

HAP21011, HAP21012, HAP21014, HAP21016, HAP21021, HAP21022, HAP21024, HAP21026, HAP21031,

HAP21032, HAP21034, HAP21036, HAP21041, HAP21042, HAP21044, HAP21046,

Hi-Force Limited – Prospect Way – Daventry – Northants NN11 8PL – United Kingdom

Tel: +44(0) 1327 301000: Fax: +44(0) 1327 706555: Website: www.hi-force.com

7.2 - Cleaning the air filter

There is an air filter inside the air inlet

connection (Fig 12).

Use a slotted tip screwdriver of the

appropriate size to unscrew the filter

from the air inlet connection until it is

extracted.

Clean the filter with compressed air

and then refit and screw it into position.

Do not over-tighten the filter or

damage may ensue.

Reconnect the air-line quick coupler

after binding the thread with Teflon

tape.

If

the

air

filter

is

excessively

contaminated or damaged, it must be

renewed.

Order

a

new

filter

from

the

manufacturer, referring to the list of

spare parts at the end of this manual.

7.3.1 - Checking the hydraulic oil on the 2,5

Litre pump (AHP1120/AHP1120R)

Periodically check that the pump contains the

correct quantity of hydraulic oil by checking

the level on the sight glass (Fig 13). If the oil

level, with cylinder retracted, is below minimum

(E, Fig 13a), refill using the recommended types

of oil.

7.3.2 - Checking the hydraulic oil on the 5/10

Litre pump (AHP1121(R)/ 1122(R)/ 1141/ 1142)

Periodically check the oil level, which must be

between the two notches on the oil cap

dipstick (F in Fig 13b).

7.4 - Hydraulic oil change

Change the oil at intervals of 250 duty hours.

This operation must be performed when the

cylinder is fully retracted: USE ONLY HI-FORCE

HFO46 OIL for your AHP Pump.

If the pump is mounted vertically,

disassemble

it

and

position

it

horizontally.

Use a slotted tip screwdriver to remove

the filler plug (Fig 1).

Empty the pump of oil by turning it

upside down over a suitable container.

Allow all the oil to flow into the

container and then fill the pump with

the quantity and type of new oil

specified above.

Clean the filler opening with a clean

cloth and refit the plug, pressing it fully

down or, if necessary, to the partially

inserted breather position.

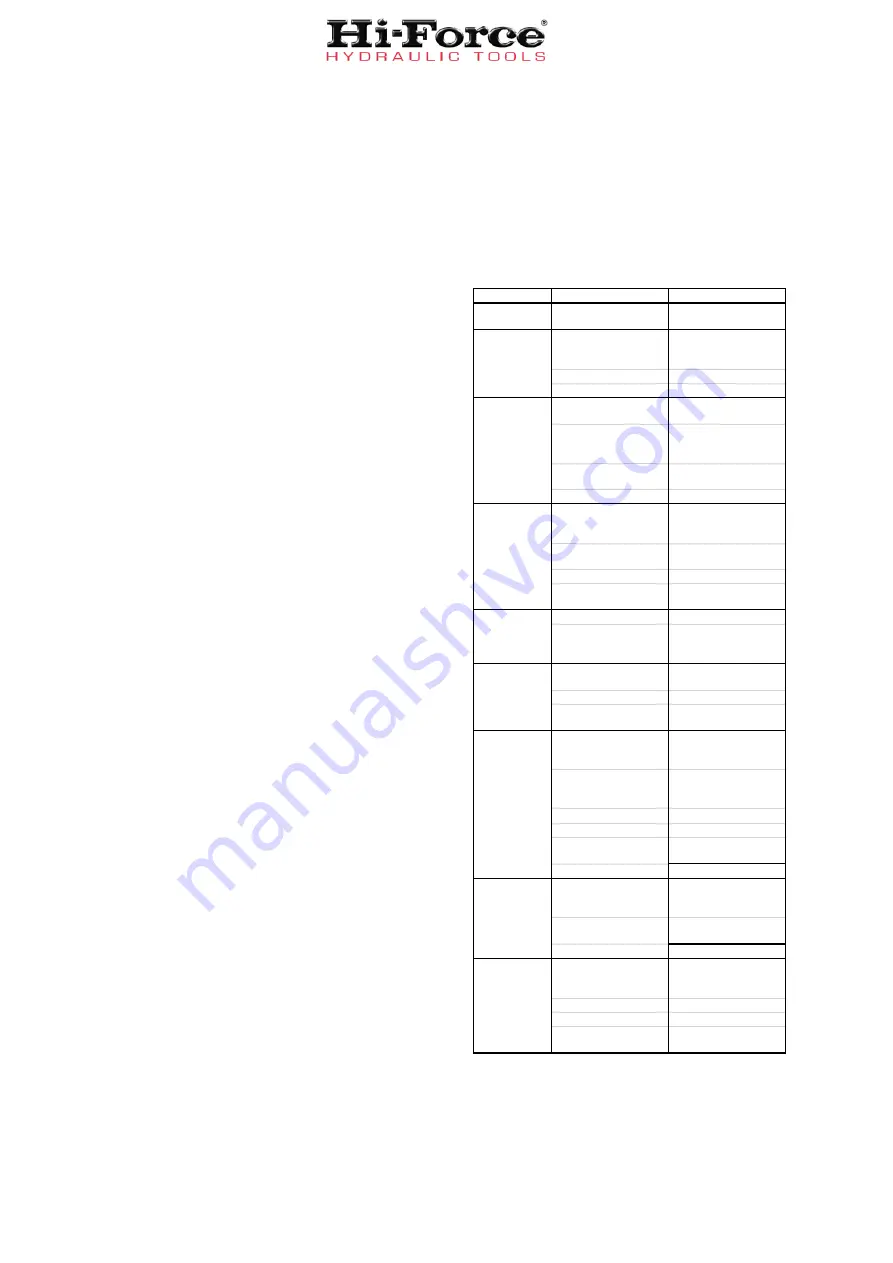

7.5 - Troubleshooting

The chart below describes the possible issues

that could occur during operation of the

pump, together with an indication of the

appropriate corrective action. If the prescribed

action fails to solve the problem, contact the

manufacturer.

PROBLEM

POSSIBLE CAUSE

CORRECTIVE ACTION

Pump cannot be

started

Compressed air line closed or

clogged

Check compressed air supply to

pump

Insufficient air pressure

Check compressed air supply to

pump is between 2.8 and 10Bar

Air filter dirty or clogged

Clean or Renew

Oil leak in the main hydraulic

circuit.

Check the circuit for leaks and

repair as necessary.

Pump internal leak

Check for leaks and return

pump to manufacturer for

repair

Low oil level

Check level and top up as

necessary

Insufficient air pressure

Check compressed air supply to

pump is between 2.8 and 10Bar

Internal relief valve incorrectly

set.

Contact the manufacturer

Oil leak in the main hydraulic

circuit

Check for oil leaks and ask the

manufacturer

Excess load

Reduce

Oil circulation fault

Check if pipelines are

obstructed or if cylinder is

working correctly

Oil leak in the main hydraulic

circuit

Check the circuit for leaks and

repair as necessary.

Pump internal fault

Check for leaks and ask the

manufacturer

Oil pressure line obstructed or

coupling incorrectly connected

Check oil pressure line.

If piston is designed to return

under gravity, ensure load is

sufficient

Increase load on cylinder

Cylinder spring broken

Repair

Cylinder release valve not

working

Repair cylinder

Oil pressure line obstructed or

coupling incorrectly connected

Check oil pressure line.

Cylinder release valve not

working

Repair cylinder

Insufficient air pressure.

Check compressed air supply to

pump is between 2.8 and 10Bar.

Air filter dirty or clogged.

Clean or Renew.

Reservoir breather plug or

screw not opened

Open breather Plug or screw as

described in section 5

Pump operates but

no pressurizes oil is

delivered

Pump fails to reach

maximum pressure

Pump delivers

pressurized oil but

load is not lifting

Piston retracts

although treadle is

not pressed on

RELEASE side

Piston fails to perform

retract stroke (single

acting cylinder)

Piston fails to perform

retract stroke (single

acting cylinder)

Pump

flow

rate

insufficient

Pump stops working

under load