© 1995-2009 Energy Saving Products Ltd.

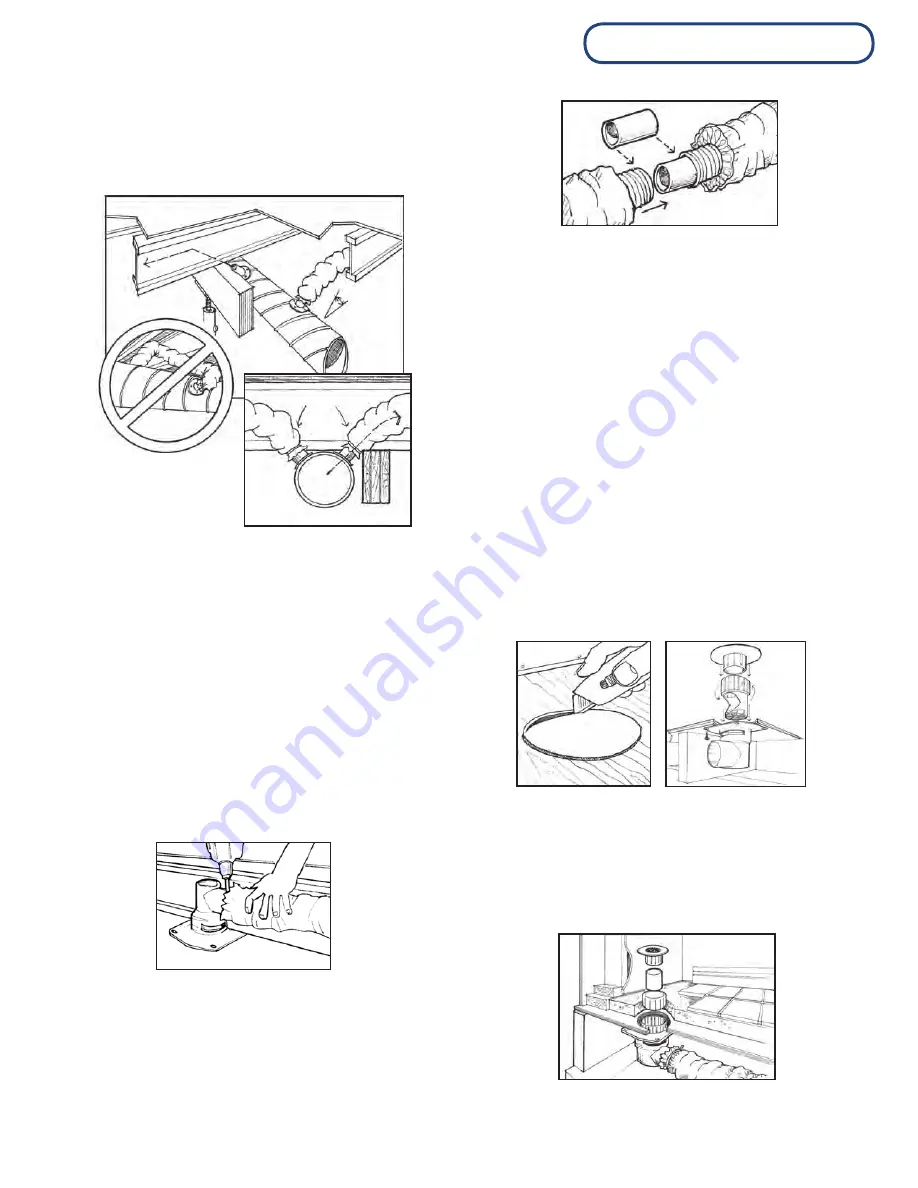

The Flexible Duct coupling is connected to the branch

Take-Off, then mechanically fastened with at least one ¼”

(6.7mm)

self tapping screw. The connection then should be

sealed with foil duct tape or an approved sealant.

Fig. 18 - Secure to plenum with gentle bends

SLIGHT

ANGLE

SLIGHT ANGLE

The Flexible Duct coupling is connected to the Rough-

In Boot, then mechanically fastened with at least one ¼”

(6.7mm)

self tapping screw

(Fig. 19)

. The connection then

should be sealed with foil duct tape or an approved sealant.

Hard angles should never be used when connecting

to the main plenum or Rough-In Boot, keep the bends as

gentle as possible

(Fig. 18)

. A hard bend should never be

created in the flexible duct as this will restrict airflow to the

outlet.

Connecting to Rough-In Boot

Fig. 19 - Mechanically Fasten

When connecting the

UFD to the AFD, attach the

branch coupling into the inner core of the UFD with foil

duct tape, connect the two branch couplings with the

branch connector tube

(Fig. 20)

. Now pull the insulation

and vapour barrier over the inner core and secure around

the outside of the vapour barrier with a cable tie. Tighten

the cable tie securely around the branch connector, inner

core, insulation, and vapour barrier.

Fig. 20 - Fasten with tie straps

Extending the AFD with a UFD kit

To complete the installation, cut out the Rough-In Cap

(Fig. 21)

and install the vent plate by sliding the vent plate

into the end of the damper tube

(Fig. 22)

. Ensure the vent

is in the

fully open position

.

If the flexible duct is in an unconditioned space, then all

connections must be taped to ensure a continuous vapour

seal. This includes the Branch Take-Off and the vent

Rough-In Boot. Try not to damage the vapour barrier on

the flexible duct. If it is damaged, holes must be taped. If

possible, try to run the flexible duct between the insulation

and the vapour barrier.

Flexible duct is not to be used in concrete applications.

Caution should be used when running metal or PVC pipe

under concrete, to ensure pipe is not crushed. For certain

applications in which hard pipe is needed, certain guidelines

must be followed. All metal ducts run in a concrete slab

must be sealed with an approved duct sealer. For vertical

runs out of the floor, it may be necessary to extend the

damper tube or vent plate collar

(Fig. 23)

, to connect to

the AFD Kit.

Unconditioned Spaces

Two Inch Metal Duct

Flexible Duct Termination

Fig. 21

Fig. 22

When the sub floor and floor finishing is too thick for

the connection of the vent plate, it may be necessary to

use an extension kit. Connect the vent plate extension

to the branch connector tube and vent plate. The branch

connector tube can be cut at different lengths so the vent

plate sits flush with the floor finishing.

Fig. 23 - Extension kit

Vent Plate Extensions

Module DUC

Installing Plenum and Branch Duct (6/9)

Module DUC Installing Plenum and Branch Duct (6/9)

Connecting to the Main Plenum

TEST SYSTEM FOR LEAKS BEFORE

INSTALLATION OF DRYWALL.

The Rough-in Boot can be insulated and vapor barriered

using the insulation and vapor barrier that is around the

flex duct. Cut the cable tie on the flex duct and pull the

insulation and vapor barrier over the flange of the Rough-in

Boot and replace cable tie. Tighten the cable tie securely

around the boot, insulation and vapor barrier.