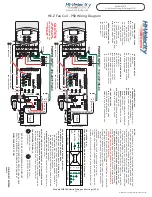

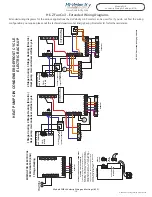

www.hi-velocity.com

© 1995-2017 Energy Saving Products Ltd.

Caution must to be used when not using the flexible duct,

the air velocity from the drilled outlet may create noise. Drilled

Outlets CANNOT be installed in a residential structure; too much

noise may be generated from the outlets. In commercial areas

with large ceilings the sound can be absorbed by the room or is

not a concern because of the ambient noises.

Drilled outlets are commonly used to supply a large area with

heating and cooling. Drilled outlets can also be used to create

a pressurized air curtain for bay doors, or large openings to the

outside environment. When drilled outlets are used with the

Hi-Velocity System a few points to remember:

•

When multiple 1

1

/4” (32mm) or 2” (51mm) holes are used,

they need to be a minimum of 6” (152mm) apart on center

(Fig. 37).

• One 1

1/4” (32mm) drilled hole is equivalent to a single 2”x10’

AFD kit (2”/51mm Rough-In Boot attached to a 10’/3.05m

piece of flex duct). With the 11/4” (32mm) drilled outlet the

throw from the outlet is up to 18’ (5.49m).

•

One 2” (51mm) drilled outlet is equivalent to two - 2”x10’ AFD

kits (2”/51mm Rough-In Boot attached to a 10’/3.05m piece

of flex duct). With the 2” (51mm) drilled outlet the throw from

the outlet is up to 30’ (9.14m) in distance.

•

Using drilled outlets larger than 2” (51mm) is not

recommended; with too large of an opening in the main

plenum the static pressure may drop to an unacceptable

level.

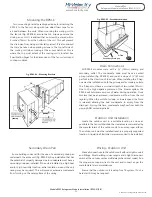

Fig. DUC-37 - 6” (152mm) Apart on center

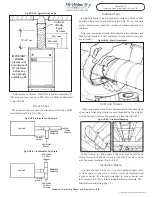

When drilled outlets are used in a ceiling install, drill the outlets

at a 45° angle to properly circulate the room air (Fig. DUC-38).

Plenum Runs on Ceiling

Fig. DUC-38 - Airflow 45° angle to floor

Fig. DUC-39 - 6” (152mm) Airflow parallel to floor

If there is an air velocity noise coming from the drilled outlets,

a static pressure reading from the plenum duct should be taken.

This reading is to be taken no closer than 18” (457mm) from supply

air outlet of fan coil. Static pressure readings are taken from the

inside edge of the plenum; do not insert pitot tube deeper than

1/4”(6.7mm) from the inside surface of the plenum.

If the static pressure is high, drilling more holes into the main

plenum will lower the static pressure and the noise level of the

system. The standard supply pressures for the Hi-Velocity System

runs between 0.7”H

2

O (174 pa) and 1.2”H

2

O (299 pa). Do not

allow the static pressure to drop below 0.7”

H

2

O

(174 pa) as this

can cause a low airflow.

For sidewall installations the outlets are drilled parallel to the

floor (Horizontal airflow). When the vents are in this configuration,

they can be used to create a pressurized air curtain.

Plenum Runs on Sidewall

Drilled Outlets

Module DUC

Installing Plenum and Branch Duct (9/9)

Module DUC Installing Plenum and Branch Duct (9/9)

-18-