18

▲

Do not lower the outrigger legs on the edge of an embankment,

soft shoulder, slope etc. Lower the outrigger legs only on a flat

surface.

▲

Slide the outrigger extension beams on both sides of the vehicle out

completely. Then lower the outrigger legs for support.

▲

If outrigger extension beams are not slide out completely,

then the crane can tip over.

▲

WARNING

Place the outrigger legs with low force on the ground.

Only for cranes with 2 outrigger legs :

Do not raise the vehicle! If you raise the vehicle with the outrigger legs

this can damage the outrigger legs.

▲

DANGER

Never operate the outrigger legs if the crane has a load.

▲

DANGER

Unfold the crane according to the

directions in the operation and

maintenance for your crane.

▲

Never unfold the loader from the

position shown in fig. 5

Summary of Contents for 160TM

Page 1: ...Ver HIAB160TM 201504 160TM OPERATING MANUAL SPARE PARTS LIST EN Cargotec Korea Ltd ...

Page 2: ...160TM OPERATING MANUAL EN Cargotec Korea Ltd ...

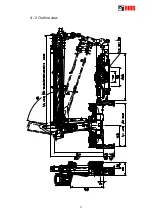

Page 31: ...31 4 2 Outline view ...

Page 33: ...33 4 4 Hydraulic diagram ...

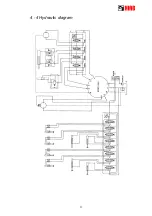

Page 67: ...160TM SPARE PARTS LIST EN Cargotec Korea Ltd ...

Page 71: ...HIAB160TM TOTAL ASS Y 2015 04 SPARE PARTS LIST 크레인 총 결합체 HIAB160TM 6 1 1 1 ...

Page 73: ...크레인 총 결합체 무선과권 HIAB160TM 6 1 2 1 HIAB160TM TOTAL ASS Y TRANSMITTER 2015 04 SPARE PARTS LIST ...

Page 75: ...BASE COLUMN ASS Y 2015 04 SPARE PARTS LIST 베이스 및 칼럼 결합체 HIAB160TM 6 2 1 ...

Page 77: ...BASE COLUMN ASS Y 2015 04 SPARE PARTS LIST 베이스 및 칼럼 결합체 HIAB160TM 6 2 1 ...

Page 79: ...BASE COLUMN ASS Y 2015 04 HIAB160TM 6 2 1 SPARE PARTS LIST 베이스 및 칼럼 결합체 ...

Page 81: ...베이스 배관도 HIAB160TM 6 3 1 BASE HOSE PIPING 2015 04 SPARE PARTS LIST ...

Page 83: ...SPARE PARTS LIST 베이스 배관도 HIAB160TM 6 3 1 BASE HOSE PIPING 2015 04 ...

Page 85: ...BASE HOSE PIPING 2015 04 SPARE PARTS LIST 베이스 배관도 HIAB160TM 6 3 1 ...

Page 87: ...2015 04 SPARE PARTS LIST 아우트리거 제어 장치 HIAB160TM 6 4 1 OUTRIGGER CONTROL SYSTEM ...

Page 89: ...SPARE PARTS LIST 아우트리거 제어 장치 HIAB160TM 6 4 1 OUTRIGGER CONTROL SYSTEM 2015 04 ...

Page 91: ...SPARE PARTS LIST 아우트리거 제어 밸브 HIAB160TM 6 5 1 OUTRIGGER CONTROL VALVE 2015 04 ...

Page 93: ...아우트리거 제어 밸브 HIAB160TM 6 5 1 OUTRIGGER CONTROL VALVE 2015 04 SPARE PARTS LIST ...

Page 95: ...HIAB160TM 6 6 1 BOOM SYSTEM 2015 04 붐 시스템 SPARE PARTS LIST ...

Page 97: ...붐 시스템 HIAB160TM 6 6 1 BOOM SYSTEM 2015 04 SPARE PARTS LIST ...

Page 99: ...붐 시스템 HIAB160TM 6 6 1 BOOM SYSTEM 2015 04 SPARE PARTS LIST ...

Page 101: ...붐 시스템 HIAB160TM 6 6 1 BOOM SYSTEM 2015 04 SPARE PARTS LIST ...

Page 103: ...붐 시스템 HIAB160TM 6 6 1 BOOM SYSTEM 2015 04 SPARE PARTS LIST ...

Page 105: ...신축 실린더 결합체 HIAB160TM 6 7 0 EXTENSION CYLINDER ASS Y 2013 05 SPARE PARTS LIST ...

Page 107: ...1단 신축 실린더 HIAB160TM 6 8 0 1st EXTENSION CYLINDER 2013 05 SPARE PARTS LIST ...

Page 109: ...1단 신축 실린더 HIAB160TM 6 8 0 1st EXTENSION CYLINDER 2013 05 SPARE PARTS LIST ...

Page 111: ...1단 신축 실린더 HIAB160TM 6 8 0 1st EXTENSION CYLINDER 2013 05 SPARE PARTS LIST ...

Page 113: ...2단 신축 실린더 HIAB160TM 6 9 0 2nd EXTENSION CYLINDER 2013 05 SPARE PARTS LIST ...

Page 115: ...2단 신축 실린더 HIAB160TM 6 9 0 2nd EXTENSION CYLINDER 2013 05 SPARE PARTS LIST ...

Page 117: ...2단 신축 실린더 HIAB160TM 6 9 0 2nd EXTENSION CYLINDER 2013 05 SPARE PARTS LIST ...

Page 119: ...3단 신축 실린더 HIAB160TM 6 10 0 3rd EXTENSION CYLINDER 2013 05 SPARE PARTS LIST ...

Page 121: ...3단 신축 실린더 HIAB160TM 6 10 0 3rd EXTENSION CYLINDER 2013 05 SPARE PARTS LIST ...

Page 123: ...HIAB160TM 6 11 0 SPARE PARTS LIST SHEAVE ASS Y 2013 05 쉬브 결합체 ...

Page 125: ...윈치 장치 HIAB160TM 6 12 1 WINCH SYSTEM 2015 04 SPARE PARTS LIST ...

Page 127: ...윈치 감속기 결합체 HIAB160TM 6 13 0 WINCH REDUCER ASS Y 2015 04 SPARE PARTS LIST ...

Page 129: ...SPARE PARTS LIST 윈치 감속기 결합체 HIAB160TM 6 13 0 WINCH REDUCER ASS Y 2015 04 ...

Page 131: ...선회 감속기 HIAB160TM 6 14 0 SLEWING REDUCER 2013 05 SPARE PARTS LIST ...

Page 133: ...선회 감속기 HIAB160TM 6 14 0 SLEWING REDUCER 2013 05 SPARE PARTS LIST ...

Page 135: ...HIAB160TM 6 14 0 SLEWING REDUCER 2013 05 SPARE PARTS LIST 선회 감속기 ...

Page 137: ...선회 모터 HIAB160TM 6 15 0 SLEWING MOTOR 2013 05 SPARE PARTS LIST ...

Page 139: ...COUNTER BALANCE VALVE D 2013 05 카운터 발란스 밸브 SPARE PARTS LIST HIAB160TM 6 16 0 ...

Page 141: ...SPARE PARTS LIST 데릭 실린더 HIAB160TM 6 17 0 DERRICK CYLINDER 2013 05 ...

Page 143: ...SPARE PARTS LIST 로타리 조인트 결합체 HIAB160TM 6 18 1 ROTARY JOINT ASS Y 2015 04 ...

Page 145: ...운전석 결합체 HIAB160TM 6 19 1 TOP SEAT ASS Y 2015 04 SPARE PARTS LIST ...

Page 147: ...운전석 결합체 HIAB160TM 6 19 1 TOP SEAT ASS Y 2015 04 SPARE PARTS LIST ...

Page 149: ...운전석 배관도 HIAB160TM 6 20 1 TOP SEAT HOSES 2015 04 SPARE PARTS LIST ...

Page 151: ...SPARE PARTS LIST 주 제어 밸브 HIAB160TM 6 21 0 MAIN CONTROL VALVE 2013 05 ...

Page 153: ...MAIN CONTROL VALVE 2013 05 SPARE PARTS LIST 주 제어 밸브 HIAB160TM 6 21 0 ...

Page 155: ...주 제어 밸브 HIAB160TM 6 21 0 MAIN CONTROL VALVE 2013 05 SPARE PARTS LIST ...

Page 157: ...SPARE PARTS LIST 아우트리거 결합체 HIAB160TM 6 22 1 OUTRIGGER ASS Y 2015 04 ...

Page 159: ...아우트리거 결합체 2015 04 OUTRIGGER ASS Y SPARE PARTS LIST HIAB160TM 6 22 1 ...

Page 161: ...HIAB160TM 6 23 1 OUTRIGGER CYLINDER 2015 04 SPARE PARTS LIST 아우트리거 실린더 ...

Page 163: ...2013 05 사이드 쉬프트 실린더 HIAB160TM 6 24 0 SIDE SHIFT CYLINDER SPARE PARTS LIST ...

Page 165: ...파일로트 체크 밸브 D HIAB160TM 6 25 0 PILOT CHECK VALVE D 2013 05 SPARE PARTS LIST ...

Page 167: ...후방 아우트리거 시스템 옵션 HIAB160TM 6 26 1 REAR OUTRIGGER SYSTEM OPTION 2015 04 SPARE PARTS LIST ...

Page 169: ...후방 아우트리거 시스템 옵션 HIAB160TM 6 26 1 REAR OUTRIGGER SYSTEM OPTION 2015 04 SPARE PARTS LIST ...

Page 171: ...후방 아우트리거 실린더 옵션 HIAB160TM 6 27 0 REAR OUTRIGGER CYLINDER OPTION 2013 05 SPARE PARTS LIST ...

Page 173: ...후방 사이드 쉬프트 실린더 옵션 HIAB160TM 6 28 0 REAR SIDE SHIFT CYLINDER OPTION 2013 05 SPARE PARTS LIST ...

Page 175: ...PILOT CHECK VALVE D OPTION 2015 04 HIAB160TM 6 29 1 SPARE PARTS LIST 파일럿 체크 밸브 옵션 ...

Page 177: ...SPARE PARTS LIST 스티커 배열 HIAB160TM 6 30 0 STICKER ARRANGEMENT 2013 05 ...

Page 179: ...스티커 배열 HIAB160TM 6 30 0 2013 05 SPARE PARTS LIST STICKER ARRANGEMENT ...

Page 181: ...전기 배선도 HIAB160TM 6 31 1 1 ELECTRIC WIRING DIAGRAM 2015 04 SPARE PARTS LIST ...

Page 183: ...전기 배선도 무선과권 HIAB160TM 6 31 2 1 ELECTRIC WIRING DIAGRAM TRANSMITTER 2015 04 SPARE PARTS LIST ...

Page 185: ...전기 와이어 결합체 HIAB160TM 6 32 1 ELECTRIC WIRE ASS Y 2015 04 SPARE PARTS LIST ...

Page 187: ...전기 결합체 HIAB160TM 6 33 1 1 ELECTRIC ASS Y 2015 04 SPARE PARTS LIST ...

Page 189: ...전기 결합체 무선과권 HIAB160TM 6 33 2 1 ELECTRIC ASS Y TRANSMITTER 2015 04 SPARE PARTS LIST ...

Page 191: ...오일 탱크 HIAB160TM 6 34 0 OIL TANK 2013 05 SPARE PARTS LIST ...

Page 193: ...오일 탱크 HIAB160TM 6 34 0 OIL TANK 2013 05 SPARE PARTS LIST ...

Page 195: ...리턴 필터 HIAB160TM 6 35 0 FILTER RETURN 2015 04 SPARE PARTS LIST ...