Maintenance and Service

8.3.3

8.3.3 Annual maintenance

Take the crane, at least once a year, to a HIAB

service workshop for inspection and maintenance.

Carry out the following maintenance at least once

a year.

Hydraulic system

• Change the oil tank filler cap.

• Change the hydraulic oil.

• Replace filters.

! NOTE

If the crane is being used in hot climates the oil

might need to be changed more often.

Slewing housing

• Change oil in the slewing housing.

8.4

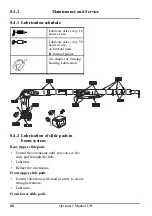

Lubrication

WARNING

Follow the lubrication schedule exactly. If you

not do so, there may be serious damage to the

crane and to add-on equipment.

Type of grease

Use lithium based grease containing EP additives

(consistencies 2 and 3 are recommended, depend-

ing on the climate).

Recommended greases:

BP LS EP 2, ESSO UNIWAY EP2 N, AGIP GR

MU/EP3, NYNÄS UNIFETT EP.

! NOTE

Avoid grease with graphite or molybdenum-

disulphide additives.

Operator's Manual GB

87