➀

➁

➂

➃

➄

74

Maintenance and Service

Operator's Manual GB

9.3

Cleaning

Clean your crane and accessories regularly, but:

• Do not use aggressive cleaning agents.

• Never use a high pressure jet cleaner on

electronic parts, plastic components, signs,

bearings, control valves, cylinders or the oil

tank. Only the cranes surface may be cleaned

with a high-pressure jet cleaner.

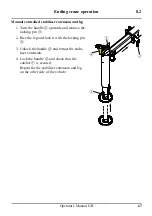

Checking the worm gear

To ensure an efficient worm drive, the shaft must

be axially secured.

Place the first boom in horizontal position and

move the boom manually from side to side while

watching the shaft:

• Demount the screws

①

and the cover

②

to

check the play. The worm shaft

③

must not

show any sign of axial movement.

• If the worm shaft

③

must be tightened, the

safety screw

④

must be loosened before the

nut

⑤

can be tightened.

• Tighten the nut to extinguish the play.

Check the worm drive at regular intervals.

Hoist

• At the regular inspection of the crane a test

load has to be lifted near to the ground and

the energy supply of the hoisting hoist has to

be switched off (switch off drive motor).

Checking time approx. 5 minutes. The load

must not sink in this condition. If the load

sinks, stop the operation and have the fault

rectified by a HIAB service workshop.

• Inspect the braking system.