91

Maintenance and Service

Operator's Manual GB

9.5.5

Lubricant must be changed the first time within

and not later than 50/60 hours from running in. In

normal environmental conditions, lubricant can

be renewed every 500 hours of work. For

recommended lubricants see 1.3 Specifications of

consumables.

For topping up and renewing, use the special

plugs provided. Replace seals under the pluga

every time you unscrew them for inspections.

It is recommended to replace the lubricant when

it is warm to prevent sludge forming.

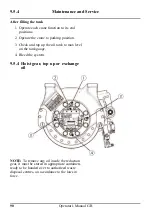

Drain oil

a. Make sure the gear oil is warm. If necessary,

heat up by reeling in and out a number of times.

b. Stop the crane with the boom system in

horizontal posotion, and switch off.

c. Place an oil container under the hoist and

remove plug

④

.

d. Drain all oil. Discard according to local

procedures.

e. Mount plug

④

again.

Fill / top up

a. Get access to the fill-opening on top and

remove the plug

①

. Remove the filling/level

plugs

③

.

b. If the winch contains a small amount of

protective oil, place an oil container under the

drum and remove plug

④

. Then close the drain

plug

④

.

c. Fill the drum with oil by a pump trough one of

the two plugs

③

until it starts leaking out of the

opening plug

③

at the opposite side. (content

approx. 0,8 liters).

d. Remowe the pump and mount all the plugs

again.

9.5.5 Bleeding air from the hydraulic

system

Bleed the air from the hydraulic system:

• after changing the hydraulic oil