8.3.3. Annual maintenance

Take the crane, at least once a year, to a Hiab authorised service workshop for inspection and

maintenance.

The workshop must carry out the following maintenance tasks at least once a year.

Hydraulic oil

• Change the hydraulic oil.

NOTE

If the workshop is equipped and the personnel prepared to do a test of the oil

quality and think that the oil change is not needed, they can postpone it on their

own responsibility.

Hydraulic system oil tank filler cap

• Change the filler cap.

• Replace filters.

Slewing housing

• Change oil in the slewing housing.

Hooks

• Replace missing or faulty parts on link assembly: shafts, safety pins and nuts.

• Replace the hook for a new one if the hook is damaged.

• Replace the latch assembly if it is damaged, missing or malfunctioning.

•

Hook 8 t and 10 t (without spring/roll pins):

replace the hook for a new one if the clevis/link or

split clevis retaining nuts are missing or damaged.

•

Hook 10 t (with spring/roll pins):

replace the two spring/roll pins and the plane bearing for a

new ones, at least once a year.

8.4. Lubrication

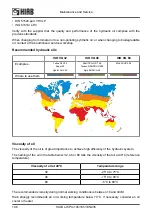

General greasing of the cranes

Incorrect or insufficient lubrication of a crane is the number one cause of premature failure.

WARNING

Before and after a long stop of the crane, lubrication is absolutely necessary. This

is especially important after a winter shutdown.

WARNING

Follow the lubrication schedule exactly. If you do not do so, you can cause serious

damage to the crane and to add-on equipment.

Maintenance and Service

100

HIAB L-HiPro 145/165/195/235