Procedure:

1.

Shut down the crane.

2.

Make sure that all the lubrication points are clean before lubricating. Dirt can damage the

parts.

3.

Lubricate all points in each section.

4.

Operate the crane through the full cycle for each section. Moving the lubricated parts is really

important to get the full and correct lubrication of all moving components.

5.

Shut down the crane and repeat the lubrication.

6.

Lubrication is finished when the grease spills out from the ends. Clean the excess grease.

WARNING

Personnel should never attempt to work on a crane that is moving. Serious injury

or death will occur if you try to work on an activated/moving crane.

CAUTION

When you use pressure grease pumps, open the plastic safety guard of the nipple

and close it at the end.

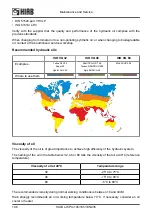

Greases

Use lithium-based grease containing EP additives (consistencies 2 and 3 are recommended,

depending on the climate).

CAUTION

Do NOT grease with graphite or molybdenum-disulphide additives.

Recommended greases:

BP LS EP 2, ESSO UNIWAY EP2 N, AGIP GR MU/EP3, NYNÄS UNIFETT EP.

Alternative:

Use a Teflon grease spray to lubricate the extensions and mobile parts.

Maintenance and Service

HIAB L-HiPro 145/165/195/235

101