8.4.2. Greasing the upper column bearing and three-point bridge

DANGER

The upper column bearing must be grease while the crane is slewed.

NOTE

The lubrication points can be fitted differently than showed in the image.

Grease through the nipples in the greasing manifold,

located on the crane base, according to the greasing signs.

If the manifold does not exist, grease directly through the

nipples, located on the upper column bearing.

If you are greasing the upper column bearing without

help:

1. Grease the upper bearing with a little grease.

2. Slew the crane a little.

3. Grease it again and repeat until the column has

completed one turn.

If you are greasing the upper column bearing with help:

One person greases the upper column bearing, while another carefully slews the crane.

DANGER

Be very careful that the person greasing the bearing does not come into contact or

get crushed by the crane!

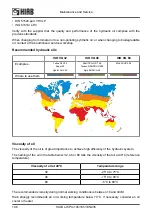

Greases:

Use lithium-based grease containing EP additives (consistencies 2 and 3 are

recommended, depending on the climate).

Do not use grease with graphite or molybdenum-disulphide additives.

8.4.3. Lubrication of the hooks

Hooks with plane bearing

If the hook cannot rotate easily without load:

• Put grease on the plane bearing surfaces (1).

• Use a heavy duty penetrating spray grease, type "ZEP

2000" or equivalent quality.

Hooks with swivel

Put grease if the swivel cannot rotate easily:

1

4

2

3

Maintenance and Service

HIAB L-HiPro 145/165/195/235

103