108

Maintenance and Service

Operator's Manual GB

8.3.2

Filters

• Check the filter indicator. If red, replace the

cartridge.

8.3.2 Monthly inspection and mainte-

nance

In addition to the daily inspection, carry out the

following each month:

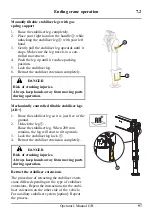

Piston rods

• In cases where the cylinder piston rod is

exposed to pollution due to the parking

location, the chromed surfaces must be

cleaned and oiled to prevent corrosion. This

needs to be done regularly.

Pivot pins and bushes

• Inspect all the pivot pins and bushings for the

crane boom and cylinders for damage, play,

etc.

Bolts and screw fixings

• Check that bolt and screw fixings are not

loose. If loose contact a HIAB service work-

shop

Cables and sensors

• Check that these are in good condition.

Lubrication schedule

• Carry out the lubrication according to the

instructions.

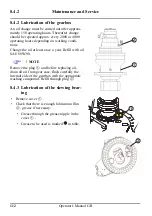

Slewing bearing / Upper column bearing

• Check that the slewing bearing / upper col-

umn bearing is lubricated sufficiently.

Hydraulic system

• Check that the hydraulic pump attachment

screws are tightened.

• Check if the oil in the hydraulic system needs

to be changed.

• Or have the oil tested by a workshop or

specialist.