DEA

114

Maintenance and Service

Operator's Manual GB

8.4.4

Shell Alvania

EP 2

248 K to 403 K

(-25º to +130º)

GREASE

S.8327

253 K to 503 K

(-20º to +230º)

Multifak

EP 2

243 K to 403 K

(-30º to +130º)

Spectron

ZKF-EP 0

253 K to 423 K

(-20º to +150º)

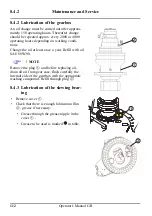

• Lubricate the bearing assemblies approxi-

mately every 100 working hours.

• Lubrication is made by injecting 5 cm3

approximately into each grease nipple around

the bearing.

• Grease to be used is marked

in table.

• Bearing should be rotated during lubrication.

• The grease filling is there to reduce friction,

seal the bearing and provide protection

against corrosion.

• Before and after prolonged stop of the crane,

lubrication is absolutely necessary. This is

especially important after a winter shutdown.