USER'S GUIDE R18 AXIAL FAN , Iss: 6.05.2021

04

INSTALLATION AND CONNECTION

Mechanical installation:

This unit should only be installed by a qualified technician. Inspect the motor bearings for proper operation prior to installation.

Do not install the fan on an unstable surface. First install the device on the application, than connect the protective earth!

The method of fixing stated is not to depend on the use of adhesives since they are not considered to be a reliable fixing means.

The fan is primarily constructed for installation with rotor on bottom or with shaft in horizontal. For other possibilities please contact for manufacturer's

support.

Ensure that the air-gap between the fan impeller and the stationary housing is constant. Distortion due to an uneven surface of basis may lead to a fan

failure. Air-gap between blade and cone-inlet (housing) should be of min. 3 mm.

Fan must be fixed to stationary housing 4x M10 through 4 holes on 910 x 910mm as indicated on enclosed technical drawing. Use screws with property

class of 8.8. Secure all threaded joints with e.g. Loctite or by using self-locking screws.

The system manufacturer or the machine builder is responsible that the inherent installation and security information are harmonized with the valid

standards and guidelines (ex. EN 13857). To prevent dangerous situation and possible injuries the height and the diameter of inlet cone must be

appropriate dimensions.

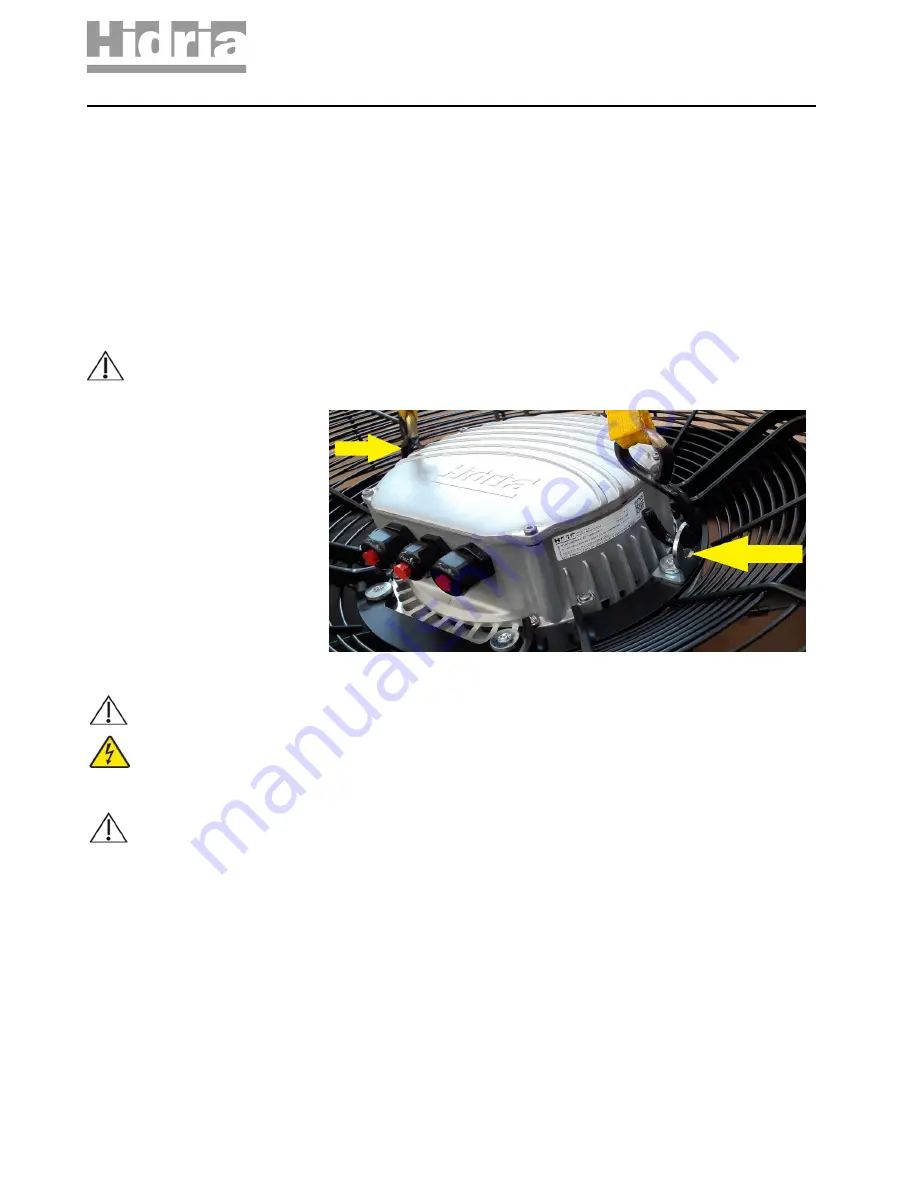

To lift the device with lifting devices, use the hangers provided for this purpose as shown on figure below. Always use suitable lifting equipment and

follow the instructions for safe work with lifting equipment. Failure to follow the instructions for safe work can lead to equipment damage or may

seriously endanger human life.

Electrical installation:

Main electrical installation must be protected against short circuit with e.g. circuit breaker: max.16A, 400Vac, Type B and installation must be

constructed properly according to valid national directives.

First install the device on the application, than connect the protective earth!

Means for disconnection must be incorporated in the fixed wiring in accordance with the wiring rules.

The fan is intended only to be connected to the fixed wiring or application’s circuit. An all-pole separating switch which must be incorporated to wiring

must disconnect also the fan.

This product can cause a d.c. current in the protective earthing conductor. Where a residual current-operated protective device (RCD) or monitoring

(RCM) device is used for protection in case of direct or indirect contact, only an RCD or RCM of Type B+ is allowed on the supply side of this product

and recommended sensitivity is 300mA with short time delayed intervention.

The electrical connection must correspond to the enclosed connection diagram.

© Copyright HIDRIA d.o.o., All rights reserved. Document is subject to change without prior notification.

5 / 10