4

5

MA-EN-OSMOSIS XENA10.1-RO-0220-22-FLC-21-V01.0

MA-EN-OSMOSIS XENA10.1-RO-0220-22-FLC-21-V01.0

•

The installation should be done by professionally qualified personnel and should not be installed

close to a heat source.

• The XENA 10.1 osmosis system needs a mains current of 220 – 240V less than 1 metre away.

• Do not repair or take the system apart on your own. If the system is not working correctly, contact

your distributor. Any tampering of the equipment by unauthorized personnel will result in the

warranty being void.

• Make sure the water passage is closed when a repair or maintenance is being carried out.

•

During the first installation or after changing the cartridges, black powder coming from the carbon

filter will enter the water. This is normal. Run the water until it’s clear.

•

Do not bend the tubes to prevent flow and pressure blockages.

• Use original spare parts to assure the correct performance of the system.

• For installation, maintenance and cartridge change, please follow this manual; otherwise the

warranty will be void.

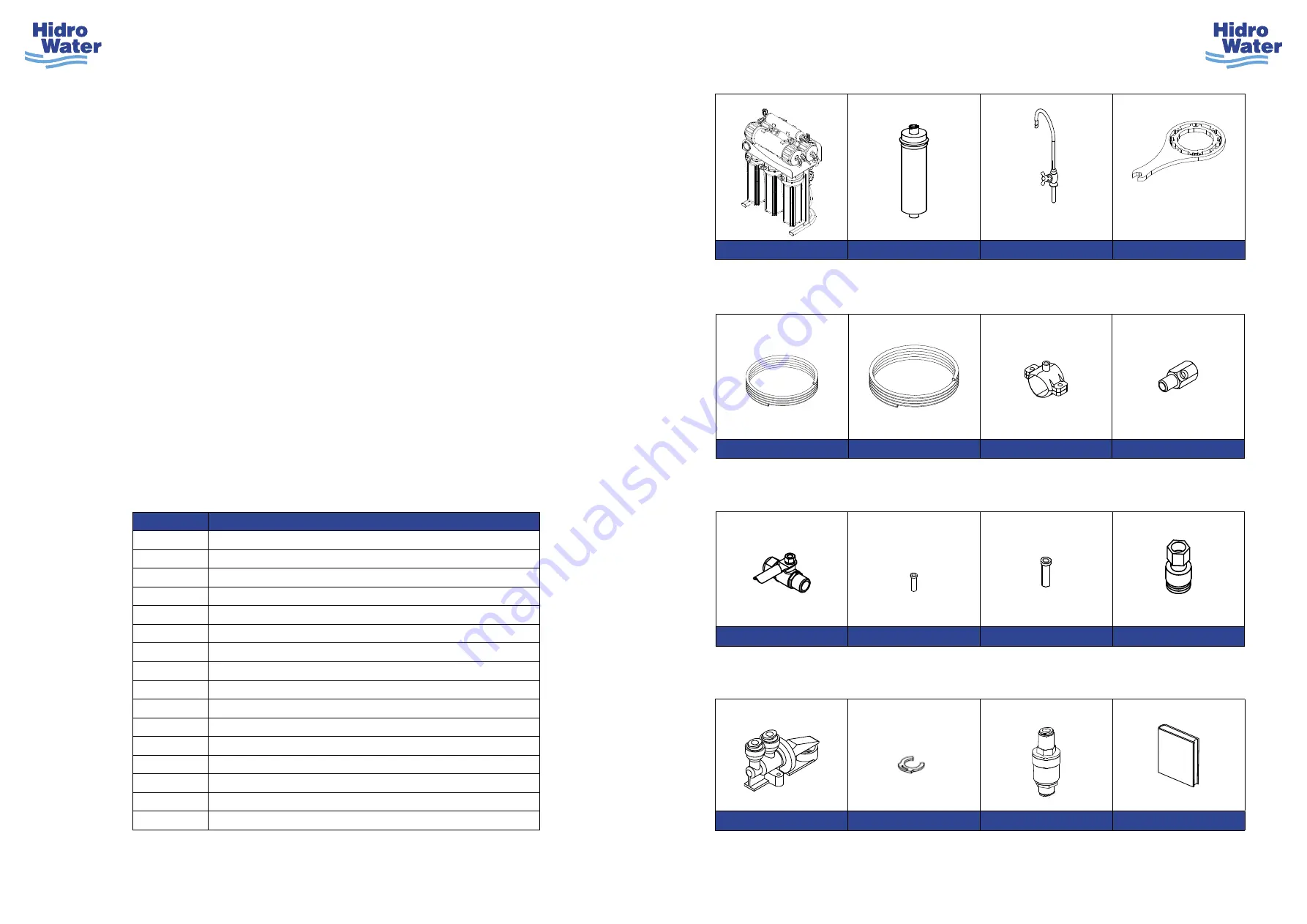

3.- CHECKING THE CONTENTS

Open the packaging and make sure that all of the components are inside, ready for the installation.

FIGURE

DESCRIPTION

1

XENA 10.1 Osmosis system main unit

2

23x12 200 GPD membrane

3

Margarita faucet

4

Filter/membrane housing wrench.

5

¼” PE Tube

6

⅜” PE Tube

7

Waste clamp

8

Feed adaptor

9

¼” M x ¼” T Brass ball valve

10

¼” Plastic insert

11

⅜” Plastic insert

12

⅜” Faucet tube adaptor

13

⅜” WATER STOP Antileak system

14

⅜” security clip

15

⅜” pressure redactor

16

Instruction manual & warranty

X-1

X-2

X-1

X-1

FIGURE 1

FIGURE 2

FIGURE 3

FIGURE 4

X-1

X-1

X-1

X-1

FIGURE 5

FIGURE 6

FIGURE 7

FIGURE 8

X-1

X-2

X-3

X-1

FIGURE 9

FIGURE 10

FIGURE 11

FIGURE 12

X-1

X-1

X-1

X-1

FIGURE 13

FIGURE 14

FIGURE 15

FIGURE 16