Rev. B 07-2013

20

10

-3.2

0.985

1

1.02

1.08

20

-7.8

0.98

0.99

1.05

1.12

30

-14.1

0.97

0.98

1.09

1.22

40

-22.3

0.965

0.97

1.14

1.25

50

-33.8

0.955

0.965

1.2

1.33

3

5

8

CCCP

0.99

1

1.02

IPCF

0.99

1

1.01

0.00005

0.0001

0.0002

CCCP

1

0.98

0.94

IPCF

1

0.98

0.95

MTEC.3800.GB-B-1 Operation and maintenance WSA series English

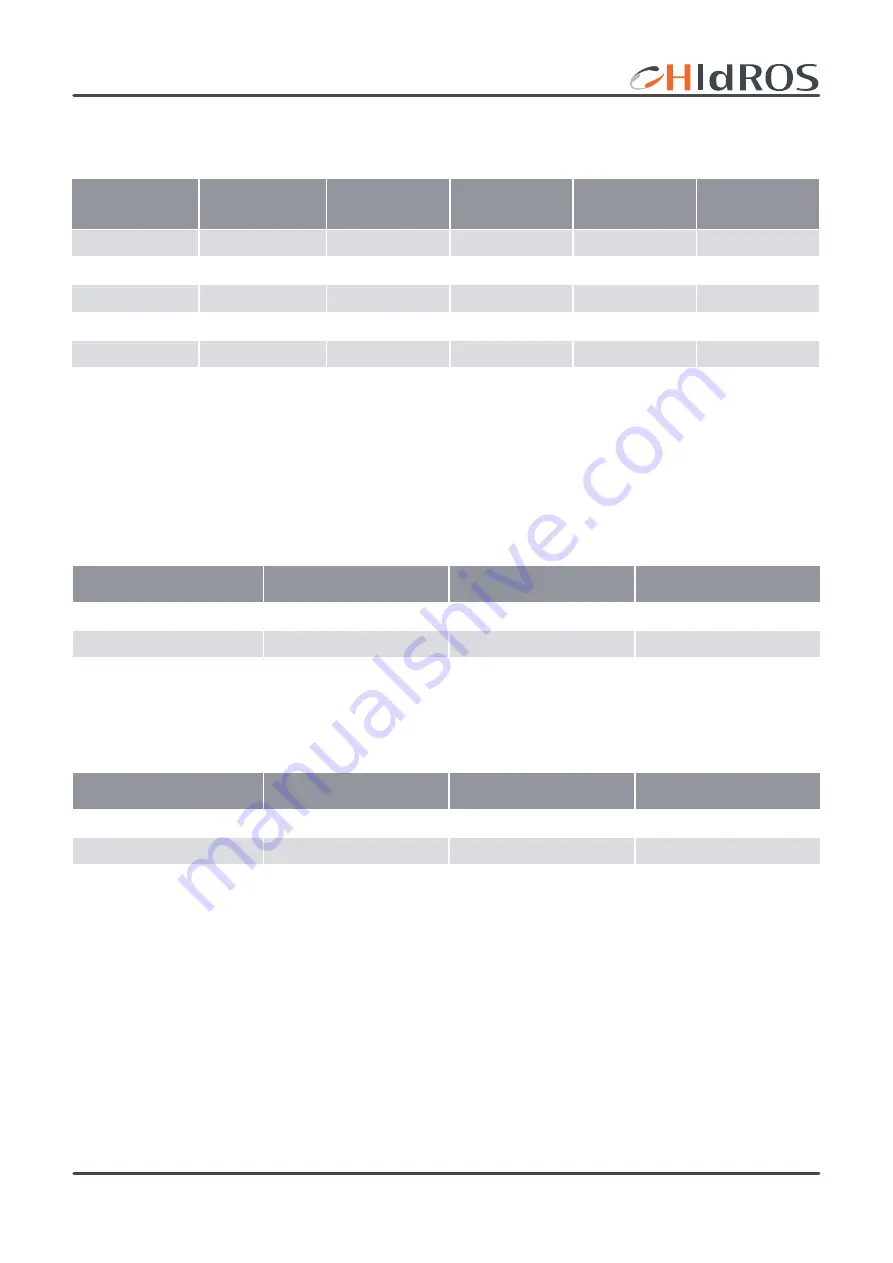

WSA

Water chiller

Glycol percentage

Freezing point (°C)

CCF

IPCF

WFCF

PDCF

Water temperature diff.(°C)

CCCP = Cooling capacity correction factor

IPCF = Input power correction factor

Fouling facto

CCCP = Cooling capacity correction factor

IPCF = Input power correction factor

3.6.1 Operation with glycol

3.6.2 Correction tables different ∆T

3.6.3 Correction tables different Fouling factors

CCF: Capacity correction factor

IPCF: Input power correction factor

WFCF: Water flow correction factor

PDCF: Pressure drops correction factor

The water flow rate and pressure drop correction factors are to be applied directly to the values given without Glycol. The water flow rate

correction factor is used to calculate the flow rate with the same temperature difference as that which would be obtained without Glycol. The

pressure drop correction factor takes into account the different flow rate obtained from the application of the flow rate correction factor.

3.6 Correction tables