18

APPENDICES B & C

A

B

̴

H

V

W

:

Natural

cord wood does not come with a speci

fi

ca on sheet like

the building materials described in Appendix C. Manu-

factured products can be made to strict, repeatable tol-

erances. Natural wood, on the other hand, varies con-

siderably depending on where it grows, the climate, the

mineral composi on of the soil, and more. Even s ll,

considerable research and scien

fi

c data is available on

di

ff

erent varie es of wood. Added to the varia ons in

the wood itself is the fact that

fi

re wood is sold by vol-

ume; most typically by the cord. As discussed in Appen-

dix A, a cord measures 4' wide X 4' high X 8' long or 128

cubic feet. Beyond those facts it begins to get murky.

The amount of burnable wood that will be available in

a given cord can vary greatly on how it is cut, whether

it is split, the sizes of the whole or split logs, and the

skill (or perhaps the integrity) of the person stacking

the wood. An apocryphal story a ributed to a Vermont

wood burner avers that well stacked wood will have spac-

es large enough for a mouse to crawl through but not

large enough for the cat chasing him. Well stacked wood

should be @ 85% wood and 15% air space. The air spac-

es are necessary to ensure proper drying. (FYI there is a

lively debate amongst experienced wood burners wheth-

er the bark side of the split wood should be up or down.)

Bark up or down the wood must be well seasoned (@

20% moisture) to be considered good

fi

rewood. Burning

green wood is ine

ffi

cient and disappoin ng; cu ng the

BTU values given below approximately in half.

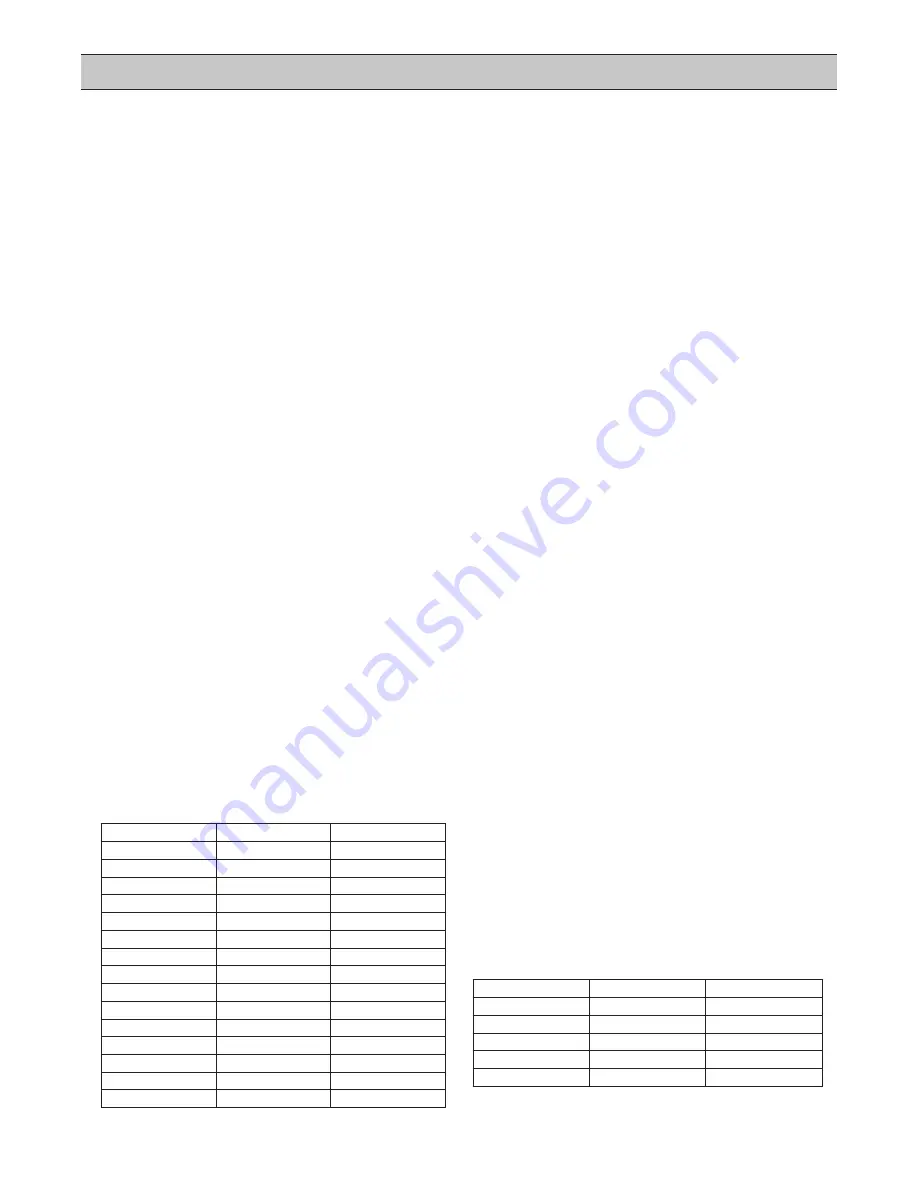

Below is an abbreviated chart that gives some approxi-

mate weight and BTU values for various species of wood.

More comprehensive lists are available on line, but a

word or two of cau on. The sta s cs can vary widely

depending on the source or, more likely, on the point

they are trying to make. The numbers can be easily ma-

nipulated by changing assump ons. If a cord of wood is

assumed to have 30% air space then the es mated avail-

able BTU's will be considerably less. Likewise, assuming

that a pound of wood at 20% moisture contains say 8000

available BTU will net an appealing, inaccurate number.

In researching data we found the varia ons considerable.

Use the numbers below as a point of comparison be-

tween species available to you, not as a score card. The

best advice is to

fi

nd an honest wood vendor and rely on

them to deliver a full cord of the best wood available.

Buy your wood well ahead of the burning season, dry it

and keep it dry, and enjoy clean e

ffi

cient wood heat.

W

S

L .

C

BTU

C

American Elm

@ 3000 lbs.

@ 20,000,000

Apple

@ 3800 lbs.

@ 27,000,000

Cherry

@ 2925 lbs.

@ 20,500,000

Hemlock

@ 2700 lbs.

@ 18,000,000

Hickory

@ 4200 lbs.

@ 27,000,000

Red Oak

@ 3500 lbs.

@ 24,500,000

Shagbark Hickory

@ 4325 lbs.

@ 27,500,000

Sugar Maple

@ 3750 lbs.

@ 24,000,000

Tamarack

@ 3250 lbs.

@ 21,000,000

White Ash

@ 3500 lbs.

@ 24,000,000

White Birch

@ 3200 lbs.

@ 20,000,000

White Cedar

@ 1915 lbs.

@ 12,500,000

White Oak

@ 4200 lbs.

@ 29,000,000

White Pine

@ 2250 lbs.

@ 15,000,000

Willow

@ 2100 lbs.

@ 14,500,000

All values are approximate and for comparison only.

A

C

̴

F

W

P

:

UL Stan-

dard 1618; the Standard for Wall Protectors, Floor Protec-

tors, and Hearth Extensions, was adopted as a standard

in 2011. UL-1618 categorizes

fl

oor and wall protectors as

Type 1 or Type 2 protec on. A seemingly minor change

in UL 1618 calls for the actual thermal proper es of

fl

oor

protec on to be speci

fi

ed in R-value in place of k-value.

In fact, that change makes it one step simpler to calculate

thermal protec on if it becomes necessary.

• Type 1: Ember Protec on = No thermal value

• Type 2: Thermal Protec on = R-value speci

fi

ed

Type 1 Ember Protec on is deemed to be a con nuous

non-combus ble material extending under the appliance

and to the front , sides, and back in the size speci

fi

ed. Any

thermal value a Type 1 protector may have is disregarded

under UL-1618. Type 2 Thermal Protec on provides ther-

mal resistance in addi on to ember protec on. Thermal

value is determined by laboratory test. UL-1618 calls for

thermal requirements to be expressed as R-values rather

than as k-values which were used in the past.

If a hearth or

fl

oor protec on is to be built on-site, or

there is an exis ng hearth already in place, then the ther-

mal resistance must be calculated. This is where having

thermal requirements expressed as an R-value vs. k-value

simpli

fi

es calcula ons. R-values can be added together.

• R-value is a unit of measure of Thermal Resistance. It

is best known as the common measure of insula on.

As with insula on, the higher the number, the be er.

• k-value is a unit of measure of Thermal Conduc vity.

k-value is the opposite (inverse) of R-value in that the

smaller the k-value the greater the resistance.

R-values for di

ff

erent materials can be added together to

determine the total R-value of composite layers of mate-

rials and k-values cannot. Conver ng k-value to R-value

is rela ve simple but it tends to add some confusion. (It

should be noted that there are other units of measure,

such as C-value, Thermal Conductance, but they are not as

commonly used in hearth applica ons.) So, again, if only

the k-value is given, then it must be converted to R-value.

(Keep in mind that the

k-value is given per inch of materi-

al.)

To convert k-value to R-value divide 1 by the k-value of

the material and

divide by the thickness of the material.

C-

values can also be converted to R-values (1 ÷ C-value) and

R-values can also be converted to k-value (inches ÷ R) but

by staying with R-values materials can be added together.

Floor protec on requirements were once commonly ex-

pressed as "3/8" of asbestos millboard k = 0.84" or similar.

The conversion is: 1 ÷ 0.84 = 1.19 X 0.375" = 0.45 R-value.

Today, with the R-value given, consider this example:

A wood heater requires R = 1.19. If 4" common brick is the

material of choice; their R-value is 0.80 (0.20 X 4"). Add

1/2" of Durock (R = 0.26) and the protec on is s ll not ad-

equate (R = 1.06). Add one more layer of 1/2" Durock and

the

fl

oor protec on is now acceptable (R = 1.32). (Brick,

le, etc. must be mortared in place, not loose laid.)

M

R-

-

Common Brick

R = 0.20 per inch k = 5.00 per inch

Durock

R = 0.52 per inch k = 1.92 per inch

Hardibacker

R = 0.51 per inch k = 1.95 per inch

Micore 160

R = 2.86 per inch k = 0.86 per inch

Marble

R = @0.09 per "

k = @11 per inch

More complete lists of material speci

fi

ca ons and more detailed

explana ons of calcula ons can be found online.