(2) Move the driving knife shaft 6 up or down to adjust the position of the driving knife 1.

16

—

—

(3) Tighten the screws 2 and 5 on the setting collars again.

30)

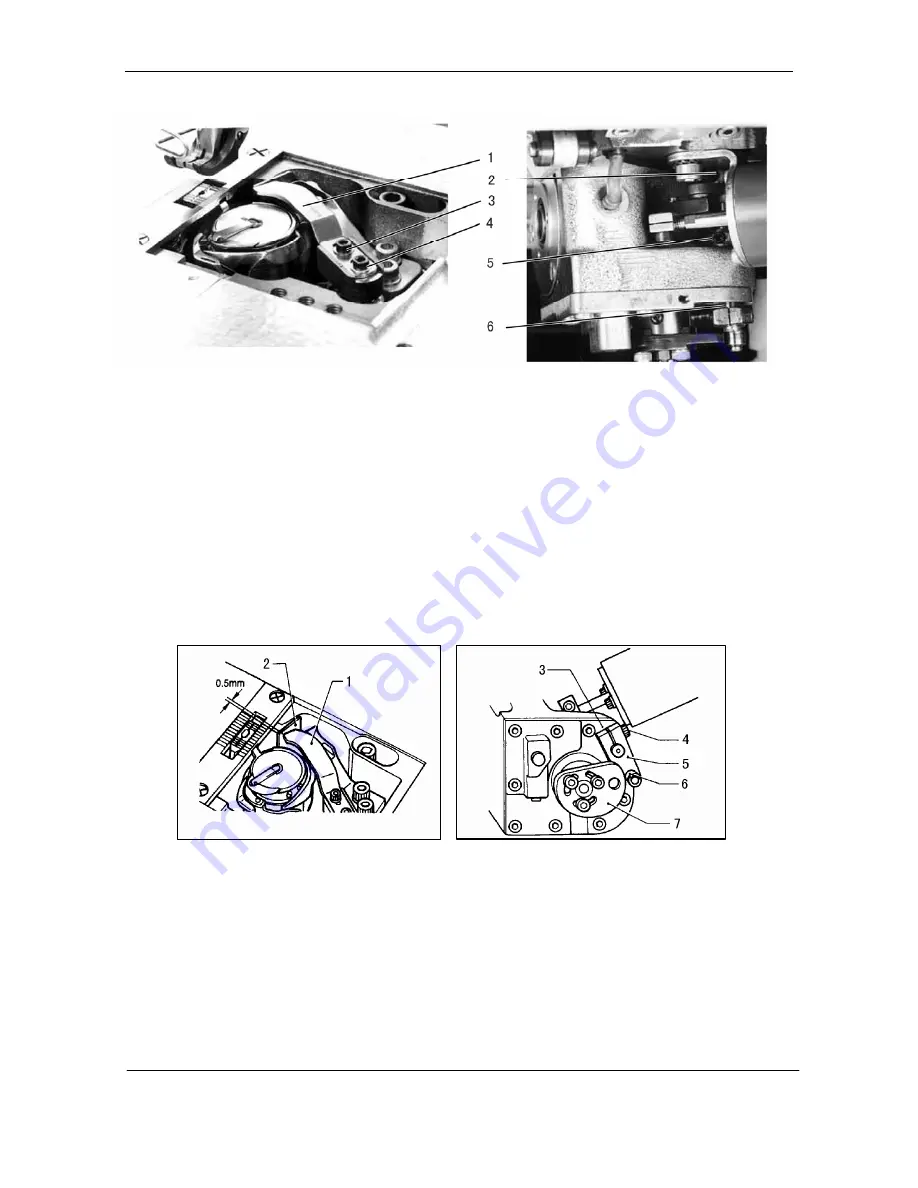

Adjusting the driving knife stop position

The distance from the blade of the fixed knife 2 to the end of the driving knife 1 should be 0.5mm when

the driving knife 1 has moved as far as possible toward the fixed knife 2.

(1) Tilt back the machine head.

(2) Turn the machine pulley to move the roller 6 of the driving knife arm 5 to the outermost side (right side)

of the thread trimmer cam 7.

(3) Loosen the bolt 4.

(4) Move the driving knife 1 so that the distance between the blade of the fixed knife 2 to the end of the

driving knife 1 is 0.5 mm, and then tighten the bolt 4.

31)

Adjusting the driving knife operating position

The standard distance from the left side of driving knife arm 1 to the screw tip on the plunger 2 of the

thread trimming solenoid is 1 mm. The clearance between the outermost side (right side) of the thread trimmer

cam 5 and the roller 6 of the driving knife arm should be 0.1 mm.

(1) Overturn the arm.

(2) Loosen the bolt 3

(3) Turn the plunger 2 of the thread trimming solen

ving knife

arm 1 to the screw tip on the plunger 2 of the thread tri

bolt 3.

oid so that the distance from the left side of dri

mming solenoid is 1 mm, and then tighten the

Summary of Contents for GC20688-BDC

Page 24: ...A ARM BED MECHANISM 21...

Page 28: ...B THREAD TENSION REGULATOR MECHANISM 25...

Page 31: ...C NEEDLE BAR AND THREAD TAKE UP MECHANISM 28...

Page 34: ...D PRESSER FOOT MECHANISM 31...

Page 37: ...E UPPER FEED LIFTING ROCK SHAFT MECHANISM 34...

Page 40: ...F STITCH REGULATOR MECHANISM 37...

Page 43: ...G FEEDING AND FEED LIFTING HOOK SHAFT MECHANISM 40...

Page 46: ...H HOOK SADDLE MECHANISM 43...

Page 50: ...I OIL LUBRICATION MECHANISM 47...

Page 53: ...J ACCESSORIES 50...

Page 55: ...K PNEUMATIC CONTROL MECHANISM 52...

Page 57: ...L KNIFFE MECHANISM 54...