L4000G4

NEW LEADER

HEADER

23

Please Give Part No., Description

& Unit Serial No.

307074-D

Page Rev. A

LUBRICATION AND MAINTENANCE CONTINUED

CONVEYOR BELT MAINTENANCE

Standard belt for the #4 chain is moderate oil resistant that is impervious to moisture, weathering, or normal action

which can be used with chemical impregnated fertilizer or oil based additives.

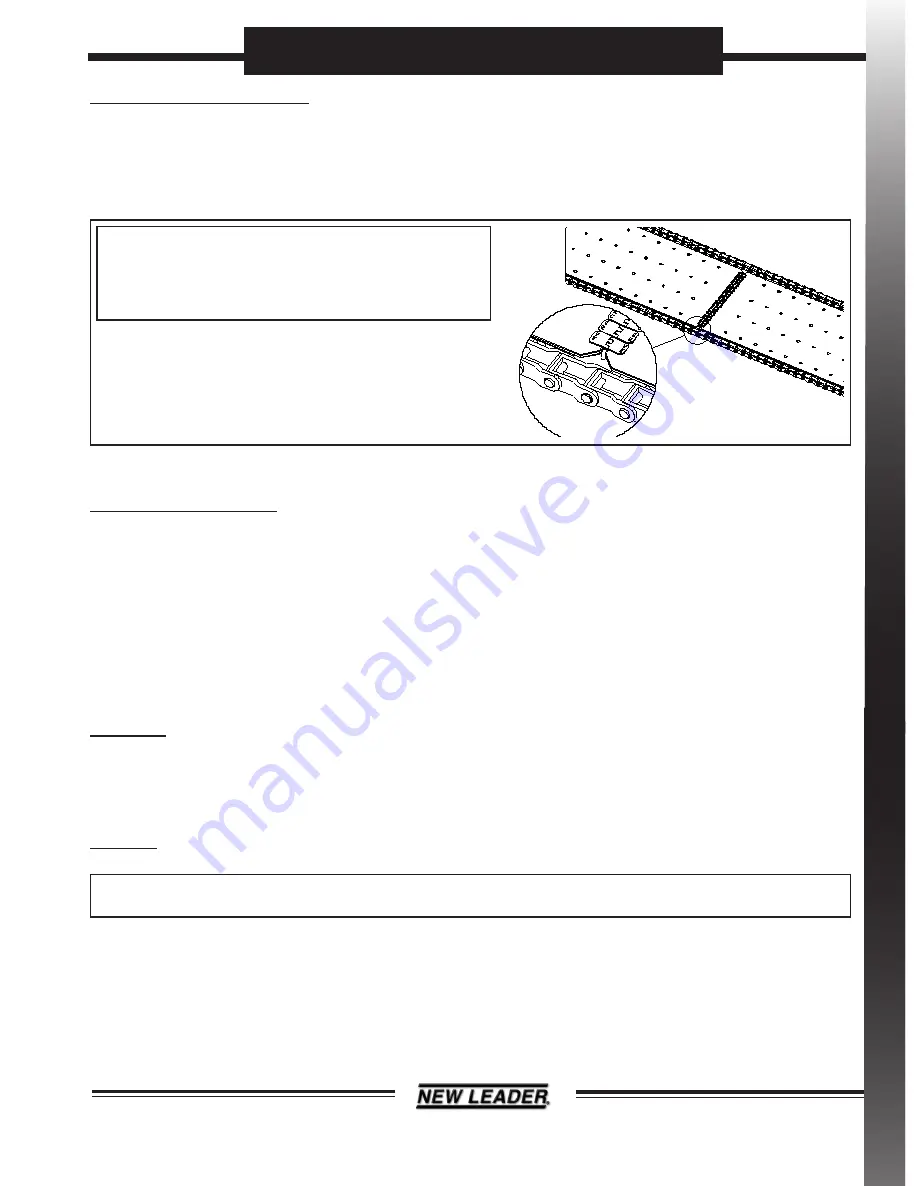

• Inspect belt fastener occasionally for wear or “raveling” of belt grip area.

• Make sure belt connecting pin is positioned correctly as shown in Figure 3.

NOTICE!

Pin must not rotate. If pin ends are not

bent down and tight against lacing, the ends

may cut into the chain shield sealers or belt

wipers.

BOTH PIN ENDS MUST

BE BENT DOWN & TIGHT

AGAINST

ENDS

OF

LACING

Figure 3 - Conveyor Belt Pin Installation

LUBRICATION OF BEARINGS

Grease in a bearing acts to prevent excessive wear of parts, protects ball races, and balls from corrosion and aids in

preventing excessive heat within the bearing. It is very important the grease maintain its proper consistency during

operation. It must not be fluid and it must not channel.

Make sure all fittings are thoroughly cleaned before grease is injected. Points to be lubricated by means of a grease

gun have standard grease fittings.

Lubricate bearings by pumping grease slowly until it forms a slight bead around the seals. This bead indicates

adequate lubrication and also provides additional protection against the entrance of dirt.

FASTENERS

Tighten all screws fasteners to recommended torque’s after first week of operation and annually thereafter. If loose

fasteners are found at anytime, tighten to recommended torque. Replace any lost or damaged fasteners or other

parts immediately. Check body mounting hardware every week.

CLEAN UP

NOTICE!

High pressure wash can inject water and/or fertilizer into control components, causing damage. Use

caution when cleaning these areas.

Thoroughly wash unit every two to three days during the operating season to maintain minimal maintenance

operation. Hose unit down under pressure to free all sticky and frozen material.

It is important the unit be thoroughly cleaned at the end of each operating season. All lubrication and maintenance

instructions should be closely followed. Repaint worn spots to prevent formation of rust.

O

P

E

R

.

&

M

A

I

N

T

.

L

U

B

R

I

C

A

T

I

O

N

&

M

A

I

N

T

E

N

A

N

C

E

All manuals and user guides at all-guides.com