English

34

5. When driving wood screws (

Fig. 10 on page 33

)

(1) Selecting a suitable driver bit

Employ plus-head screws, if possible, since the driver bit easily slips o

ff

the heads of

minus-head screws.

Screw heads or bits will be damaged unless a bit appropriate for the screw diameter is

employed to drive in the screws.

(2) Driving in wood screws.

○

Prior to driving in wood screws, make pilot holes suitable for them in the wooden board.

Apply the bit to the screw head grooves and gently drive the screws into the holes.

○

After rotating the rotary hammer at low speed for a while until the wood screw is partly

driven into the wood, squeeze the trigger more strongly to obtain the optimum driving force.

CAUTION

Exercise care in preparing a pilot hole

suitable for the wood screw taking the

hardness of the wood into consideration.

Should the hole be excessively small or

shallow, requiring much power to drive

the screw into it, the thread of the wood

screw may sometimes be damaged.

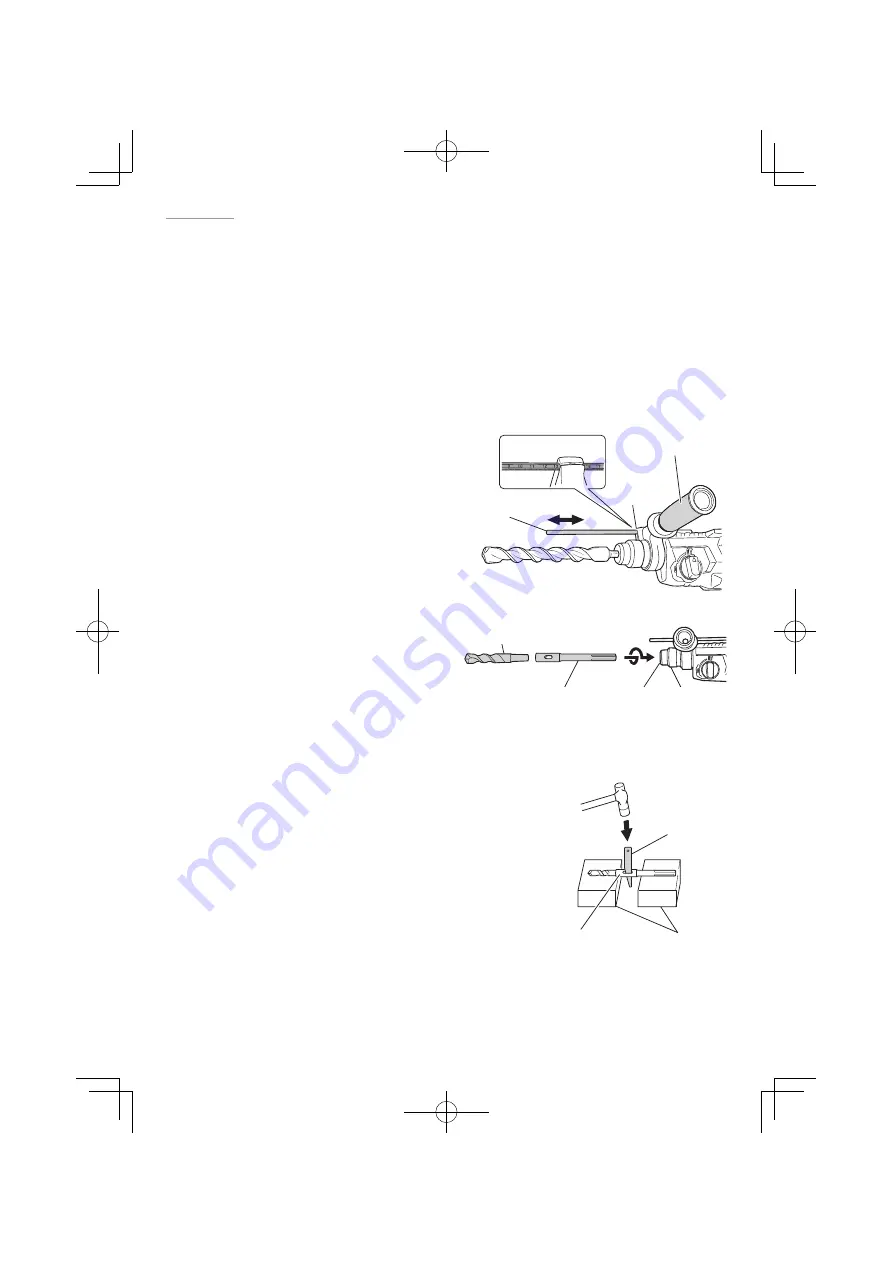

6. Using depth gauge (

Fig. 11

)

(1) Loosen the side handle, and insert the

depth gauge into the mounting hole on the

side handle.

(2) Adjust the depth gauge position according

to the depth of the hole and tighten the side

handle securely.

7. How to use the drill bit (taper shank) and

the taper shank adapter

(1) Mount the taper shank adapter to the rotary

hammer (

Fig. 12

).

(2) Mount the drill bit (taper shank) to the taper shank

adapter (

Fig. 12

).

(3) Turn the switch ON, and drill a hole in prescribed depth.

(4) To remove the drill bit (taper shank), insert the cotter

into the slot of the taper shank adapter and strike the

head of the cotter with a hammer supporting on a rests

(

Fig. 13

).

Fig. 11

Side handle

Mounting

hole

Depth gauge

Fig. 12

Drill bit

Front cap Grip

Taper

shank

adapter

Cotter

Taper shank adapter Rest

000Book̲DH24PG2̲ChS.indb 34

000Book̲DH24PG2̲ChS.indb 34

2019/02/07 14:45:18

2019/02/07 14:45:18