6

English

STANDARD ACCESSORIES

In addition to the main unit (1 unit), the package

contains the accessories listed in the below.

○

Plastic case ................................................................ 1

○

Side handle ................................................................. 1

○

Depth gauge .............................................................. 1

○

Drill chuck holder ....................................................... 1

Standard accessories are subject to change without notice.

APPLICATIONS

Rotation and hammering function

○

Drilling anchor holes

○

Drilling holes in concrete

○

Drilling holes in tile

Rotation only function

○

Drilling in steel or wood

○

Tightening machine screws, wood screws

Hammering only function

○

Light-duty chiselling of concrete, groove digging and

edging.

SPECIFICATIONS

The speci

fi

cations of this machine are listed in the Table on

page 92.

NOTE

Due to HiKOKI’s continuing program of research and

development, the speci

fi

cations herein are subject to

change without prior notice.

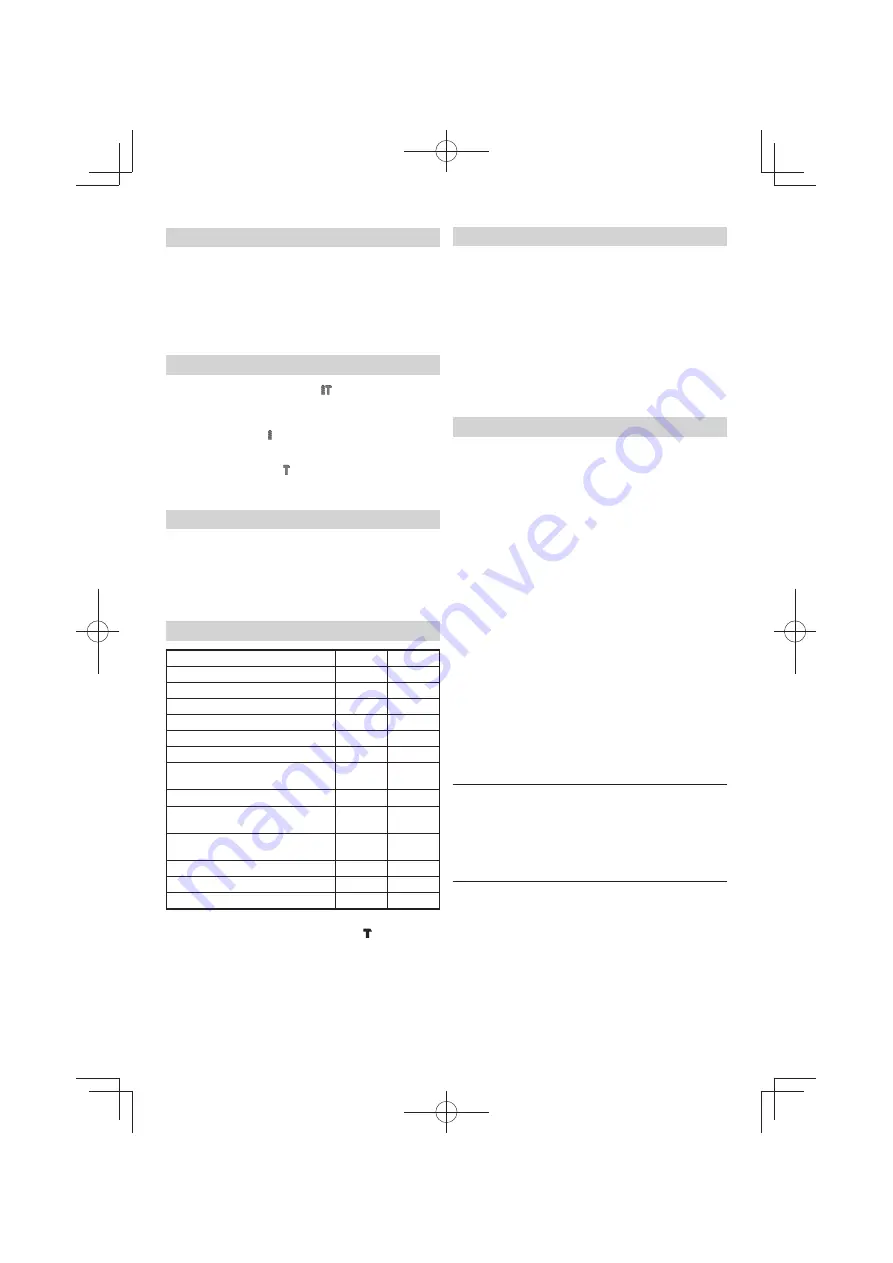

MOUNTING AND OPERATION

Action

Figure

Page

Inserting SDS-plus tools

1

2

Removing SDS-plus tools

2

2

Selecting rotation direction

3

2

Selecting the operating mode

4

2

Adjusting the drilling depth

5

2

Changing the chisel position

6

2

Removing the quick release

chuck*

1

7

3

Inserting the quick release chuck

8

3

Inserting round shank applications

tools

9

3

Switching on and o

ff

and setting

the speed

10

3

Locking-on the On / O

ff

switch

11

3

Releasing the On / O

ff

switch

12

3

Selecting accessories*

2

–

93

*1 If it is hard to pull out the drill chuck holder or the drill bit

holder, align the change lever with the mark and turn

the lock grip.

*2 For detailed information regarding each tool, contact a

HiKOKI authorized service center.

LUBRICATION

This Rotary Hammer is of full air-tight construction to protect

against dust and to prevent lubricant leakage.

Therefore, this Rotary Hammer can be used without

lubrication for long periods. Replace the grease whenever

you change the carbon brush to maintain the service life.

Further use of the rotary hammer with lock o

ff

grease will

cause the machine to seize up reduce the service life.

CAUTION

A special grease is used with this machine, therefore,

the normal performance of the machine may be badly

a

ff

ected by use of other grease. Please be sure to let

one of our service agents undertake replacement of the

grease.

MAINTENANCE AND INSPECTION

1. Inspecting the tools

Since use of a dull tool will cause motor malfunctioning

and degraded e

ffi

ciency, replace the tool with new ones

or resharpen them without delay when abrasion is noted.

2. Inspecting the mounting screws

Regularly inspect all mounting screws and ensure that

they are properly tightened. Should any of the screws be

loose, retighten them immediately. Failure to do so could

result in serious hazard.

3. Maintenance of the motor

The motor unit winding is the very “heart” of the power

tool.

Exercise due care to ensure the winding does not

become damaged and/or wet with oil or water.

4. Inspecting the carbon brushes

For your continued safety and electrical shock

protection, carbon brush inspection and replacement on

this machine should ONLY be performed by a HiKOKI

Authorized Service Center.

5. Replacing supply cord

If the replacement of the supply cord is necessary, this

has to be done by the manufacturer of this agent in order

to avoid a safety hazard.

CAUTION

In the operation and maintenance of power tools, the

safety regulations and standards prescribed in each

country must be observed.

GUARANTEE

We guarantee HiKOKI Power Tools in accordance with

statutory/country speci

fi

c regulation. This guarantee does

not cover defects or damage due to misuse, abuse, or

normal wear and tear. In case of complaint, please send

the Power Tool, undismantled, with the GUARANTEE

CERTIFICATE found at the end of this Handling instruction,

to a HiKOKI Authorized Service Center.

00Book̲DH24PMH.indb 6

00Book̲DH24PMH.indb 6

2021/05/13 16:47:18

2021/05/13 16:47:18