5

English

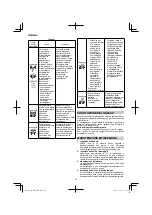

Flash

1

Tool fails to

startup or has

shut down due

to the unit being

connected to a

power source

whose voltage is

either too high or

too low.

2

Tool has shut

down due to a

voltage signal

read error that

occurred from

the unit’s power

cord being

plugged in and

out at short

intervals.

(Circuit protection

function)

1

Connect the unit

to a power supply

matching the input

voltage speci

fi

ed

on the nameplate.

Press the rotation

speed selector

switch to recover.

2

Allow for an interval

of 3 seconds or

more when plugging

the power cord

in and out. Press

the rotation speed

selector switch to

recover.

Flash

Sensor signal read

error.

(Control monitoring

function)

Press the rotation

speed selector switch

to recover. Repair may

be required if this error

continuously occurs.

GREASE REPLACEMENT

This Rotary Hammer is of full air-tight construction to protect

against dust and to prevent lubricant leakage.

Therefore, this Rotary Hammer can be used without

lubrication for long periods. Replace the grease as described

below.

Grease Replacement Period

After purchase, replace grease after every 6 months of

usage. Ask for grease replacement at the nearest authorized

Service Center.

MAINTENANCE AND INSPECTION

1. Inspecting the drill bits

Since use of a dull tool will cause motor malfunctioning

and degraded e

ffi

ciency, replace the drill bit with new

ones or resharpen them without delay when abrasion is

noted.

2. Inspecting the mounting screws

Regularly inspect all mounting screws and ensure that

they are properly tightened. Should any of the screws be

loose, retighten them immediately. Failure to do so could

result in serious hazard.

3. Maintenance of the motor

The motor unit winding is the very “heart” of the power

tool.

Exercise due care to ensure the winding does not

become damaged and/or wet with oil or water.

4. Replacing supply cord

If the replacement of the supply cord is necessary, this

has to be done by the manufacturer of this agent in order

to avoid a safety hazard.

CAUTION

In the operation and maintenance of power tools, the

safety regulations and standards prescribed in each

country must be observed.

GUARANTEE

We guarantee HiKOKI Power Tools in accordance with

statutory/country speci

fi

c regulation. This guarantee does

not cover defects or damage due to misuse, abuse, or

normal wear and tear. In case of complaint, please send

the Power Tool, undismantled, with the GUARANTEE

CERTIFICATE found at the end of this Handling instruction,

to a HiKOKI Authorized Service Center.

IMPORTANT

Correct connection of the plug

The wires of the main lead are coloured in accordance

with the following code:

Blue: — Neutral

Brown: — Live

As the colours of the wires in the main lead of this tool may

not correspond with the coloured markings identifying the

terminals in your plug proceed as follows:

The wire coloured blue must be connected to the terminal

marked with the letter N or coloured black. The wire

coloured brown must be connected to the terminal marked

with the letter L or coloured red. Neither core must be

connected to the earth terminal.

NOTE:

This requirement is provided according to BRITISH

STANDARD 2769: 1984.

Therefore, the letter code and colour code may not be

applicable to other markets except The United Kingdom.

Information concerning airborne noise and vibration

The measured values were determined according to

EN60745 and declared in accordance with ISO 4871.

Measured A-weighted sound power level:

106 dB (A) (DH45ME)

107 dB (A) (DH45MEY)

Measured A-weighted sound pressure level:

95 dB (A) (DH45ME)

96 dB (A) (DH45MEY)

Uncertainty K: 3 dB (A).

Wear hearing protection.

Vibration total values (triax vector sum) determined

according to EN60745.

Hammer drilling into concrete:

Vibration emission value

ah

,

HD

= 13.5 m/s

2

(DH45ME)

8.8 m/s

2

(DH45MEY)

Uncertainty K = 1.5 m/s

2

Equivalent chiselling value:

Vibration emission value

a

h

,

CHeq

= 14.2 m/s

2

(DH45ME)

9.2 m/s

2

(DH45MEY)

Uncertainty K = 1.5 m/s

2

0000Book̲DH45ME.indb 5

0000Book̲DH45ME.indb 5

2017/11/30 15:39:39

2017/11/30 15:39:39