12

English

ABOUT THE PROTECTION

FUNCTION

This tool has a built-in protection circuit for preventing

damage to the unit in the event of an abnormality. Depending

on the following, the display lamp and the indicator lamp will

fl

ash, and the unit will cease to operate. Verify the problem

indicated by the

fl

ashing and take the necessary steps to

correct the problem.

When pressing the changeover switch, do so when the

switch is not being pulled.

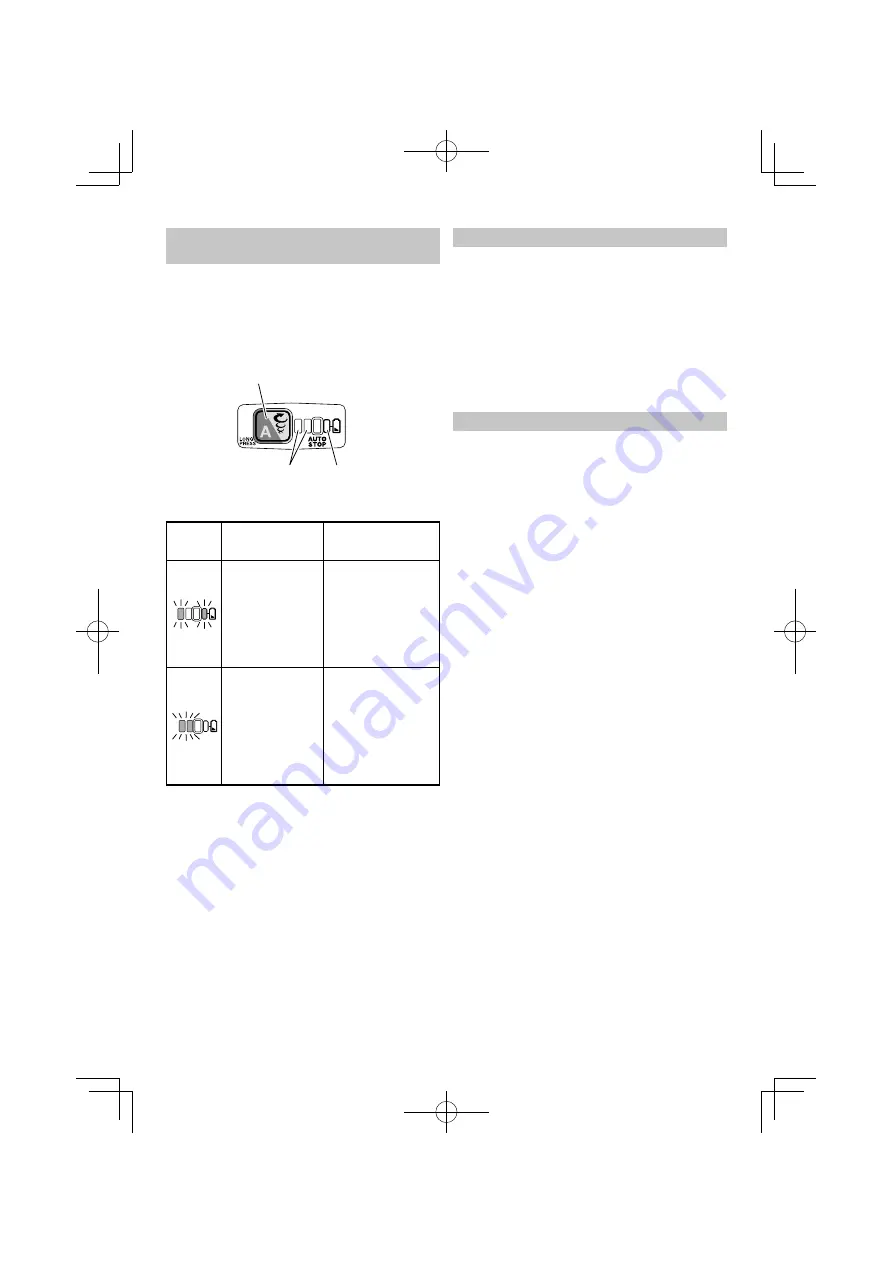

Changeover switch

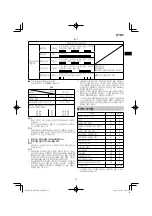

Display lamp Indicator lamp

Fig. 18

Table 3

Display

lamp

fl

ashing

Cause

Solution

Operation has

ceased because the

internal temperature

has exceeded the

temperature limit.

(High temperature

protection function)

Allow the unit to cool

for 15 to 30 minutes.

When the temperature

goes down and the

display lamp and the

indicator lamp blinking

stops, pull the switch

trigger to recover

operation.

Sudden

overburdening of

the tool bit has

activated the RFC,

stopping further

operation of the tool.

RFC (See page 11

“REACTIVE

FORCE

CONTROL”)

Release the switch

trigger and leave it

until the display lamp

blinking stops. Pull the

switch trigger again to

recover operation.

Before continuing

operation, remove

the cause of the

overburden.

NOTE

Despite taking steps to correct a problem, the display

lamp may continue to blink. Should this be the case, the

unit may require repair. If so, please contact the outlet

from which this product was purchased for repairs.

LUBRICATION

Low viscosity grease is applied to this rotary hammer so

that it can be used for a long period without replacing the

grease. Please contact the nearest service center for grease

replacement when any grease is leaking form loosened

screw.

Further use of the rotary hammer despite the grease

shortage causes damage to reduce the service life.

CAUTION

A

speci

fi

c grease is used with this machine, therefore,

the normal performance of the machine may be badly

a

ff

ected by use of di

ff

erent grease. Please be sure to let

one of our service centers to undertake replacement of

the grease.

MAINTENANCE AND INSPECTION

CAUTION

Be sure to turned o

ff

the switch and remove the battery

before maintenance and inspection.

1. Inspecting the tool

Since use of as dull tool will degrade e

ffi

ciency and

cause possible motor malfunction, sharpen or replace

the tool as soon as abrasion is noted.

2. Inspecting the mounting screws

Regularly inspect all mounting screws and ensure that

they are properly tightened. Should any of the screws be

loose, retighten them immediately. Failure to do so could

result in serious hazard.

3. Maintenance of the motor

The motor unit winding is the very “heart” of the power

tool. Exercise due care to ensure the winding does not

become damaged and/or wet with oil or water.

4. Inspection of terminals (tool and battery)

Check to make sure that swarf and dust have not

collected on the terminals.

On occasion check prior, during and after operation.

CAUTION

Remove any swarf or dust which may have collected on

the terminals.

Failure to do so may result in malfunction.

5. Cleaning on the outside

When the power tool is stained, wipe with a soft dry cloth

or a cloth moistened with soapy water. Do not use chloric

solvents, gasoline or paint thinner, for they melt plastics.

6. Cleaning the battery installation compartment and

the battery

After drilling concrete, if concrete dust has accumulated

on the battery installation compartment and the battery,

clean o

ff

the accumulated concrete dust with air gun or a

dry cloth before using the tool. (

Fig. 16

)

Also, after cleaning, ensure that the battery can be

installed and removed smoothly from the tool.

CAUTION

Using the tool when the battery is covered with concrete

dust may lead to accidents such as the battery falling

during use.

Furthermore, such use may cause a malfunction or

contact failure between the battery and the terminals.

0000Book̲DH12DD̲Asia.indb 12

0000Book̲DH12DD̲Asia.indb 12

2020/10/02 19:03:24

2020/10/02 19:03:24