4

English

1. Switch operation (Fig. 4)

○ When the switch trigger (4) is depressed, the tool

rotates. When the trigger is released, the tool stops.

○ The rotational speed can be controlled by varying the

amount that the switch trigger (4) is pulled. Speed is low

when the switch trigger is pulled slightly and increases

as the switch trigger is pulled more.

2. Switching tightening mode (see Fig. 2)

Each press of mode switch (2) will change the impact

rate. Switch (4) must be switched OFF when conducting

this operation. Use A or B for light tasks, and C or D for

heavy tasks.

3. The protection function

To protect the tool, the protection function will be

activated, automatically shutting down the unit in the

event of any problems. (

Table 1

)

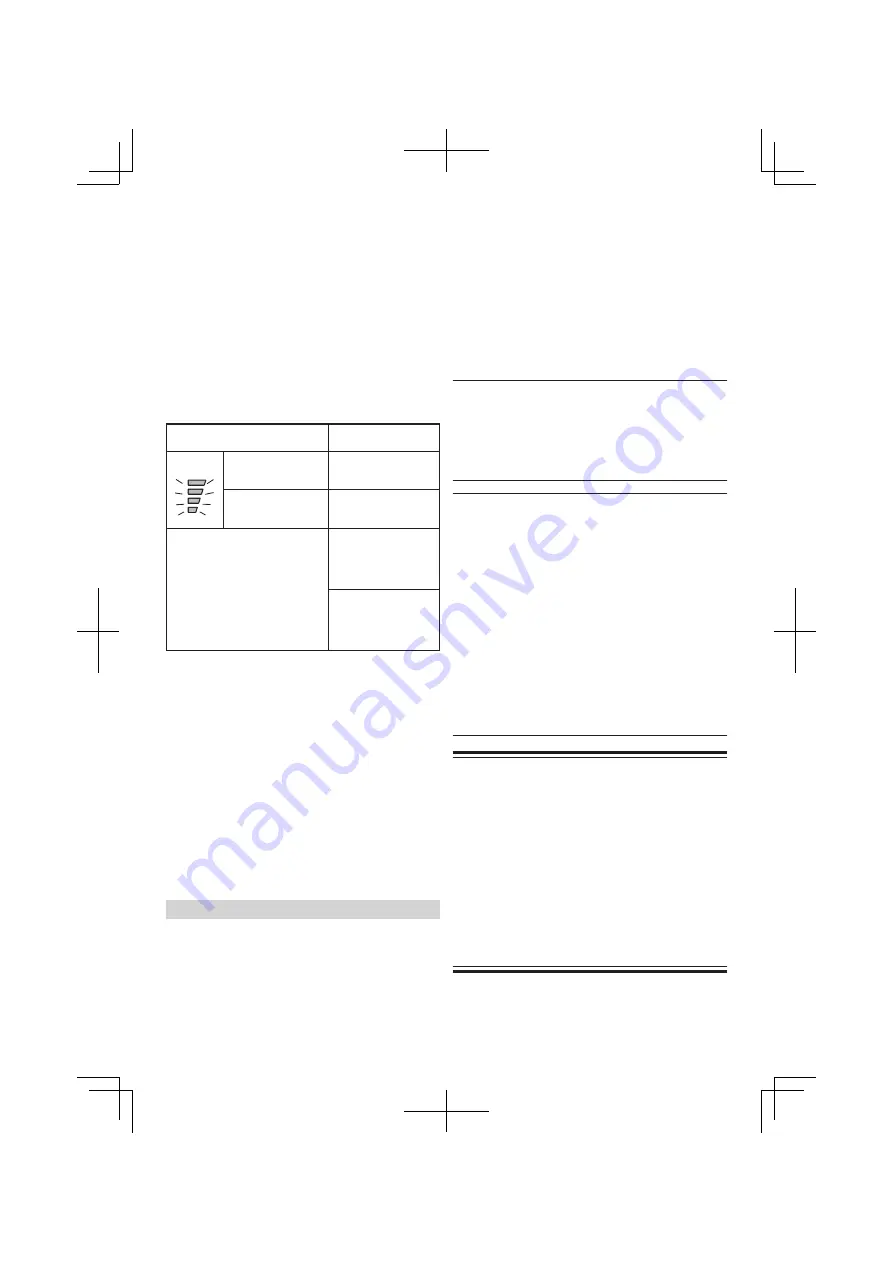

Table 1

Mode Indicator Lamp (3)

(see

Fig. 2

)

Cause of Shutdown

Flashing

Fast repeated flashes

Flashes on and off with

0.1-second intervals

Automatic shutdown

initiated by excessive

load (*1)

Slow repeated flashes

Flashes on and off with

1-second intervals

Automatic shutdown

initiated due to sensor

detection trouble (*2)

Flashing during mode operation

Automatic shutdown

initiated due to the tool’s

internal temperature

exceeding the specified

temperature level (*3)

Automatic shutdown

initiated due to

approximately 5 minutes

of continuous no-load

operation (*4)

*1 Excessive load protection function

For excessive load conditions, the tool will shutdown to

prevent damage.

Discontinue the heavy load task and press mode switch

(2) to reset the tool.

*2 Control monitoring function

Press mode switch (2) to reset the tool.

Continual occurrences of this situation may be the result

of damage to the tool.

*3 Increased temperature protection function

Automatic shutdown is activated to prevent damage

from high temperatures.

The tool’s internal temperature will increase for tasks

involving the use of large currents of electricity, or when

used in high temperature environments.

Please allow the tool to rest for 10 to 15 minutes before

continuing a task.

*4 Continuous operation prevention function

Shutdown will occur in the event of continuous operation

while the switch remains ON.

MAINTENANCE AND INSPECTION

1. Inspecting the socket

A worn or deformed hex or a square-holed socket will

not give an adequate tightness to the fitting between the

nut or anvil, consequently resulting in loss of tightening

torque. Pay attention to wear of socket holes periodically,

and replace with a new one if needed.

2. Inspecting the mounting screws

Regularly inspect all mounting screws and ensure that

they are properly tightened. Should any of the screws be

loose, retighten them immediately. Failure to do so could

result in serious hazard.

3. Maintenance of the motor

The motor unit winding is the very “heart” of the power tool.

Exercise due care to ensure the winding does not

become damaged and/or wet with oil or water.

4. Replacing supply cord

If the replacement of the supply cord is necessary, this

has to be done by the manufacturer of this agent in order

to avoid a safety hazard.

CAUTION

In the operation and maintenance of power tools, the

safety regulations and standards prescribed in each

country must be observed.

GUARANTEE

We guarantee HiKOKI Power Tools in accordance with

statutory/country specific regulation. This guarantee does

not cover defects or damage due to misuse, abuse, or

normal wear and tear. In case of complaint, please send

the Power Tool, undismantled, with the GUARANTEE

CERTIFICATE found at the end of this Handling instruction,

to a HiKOKI Authorized Service Center.

IMPORTANT

Correct connection of the plug

The wires of the main lead are coloured in accordance

with the following code:

Blue: — Neutral

Brown: — Live

As the colours of the wires in the main lead of this tool may

not correspond with the coloured markings identifying the

terminals in your plug proceed as follows:

The wire coloured blue must be connected to the terminal

marked with the letter N or coloured black. The wire

coloured brown must be connected to the terminal marked

with the letter L or coloured red. Neither core must be

connected to the earth terminal.

NOTE:

This requirement is provided according to BRITISH

STANDARD 2769: 1984.

Therefore, the letter code and colour code may not be

applicable to other markets except The United Kingdom.

Information concerning airborne noise and vibration

The measured values were determined according to

EN62841 and declared in accordance with ISO 4871.

Measured A-weighted sound power level: 98 dB (A)

Measured A-weighted sound pressure level: 111 dB (A)

Uncertainty K: 3 dB (A).

Wear hearing protection.

Vibration total values (triax vector sum) determined

according to EN62841.

Impact tightening of fasteners of the maximum capacitiy of

the tool:

Vibration emission value

a

h

= 13.2 m/s

2

Uncertainty K = 1.5 m/s

2

The declared vibration total value has been measured in

accordance with a standard test method and may be used

for comparing one tool with another.

It may also be used in a preliminary assessment of exposure.

0000Book_WR14VE.indb 4

2019/03/05 16:45:10