Terminal Box

·

Installation Guide

19

1).

Check to ensure the O-shape ring stays in terminal box.

2).

Align the locating hole of the cover with the locating pin on

box, and gently lower the cover back to the box.

Note:

When lowering the cover, prevent the explosion suppression

surfaces from bump or scratch.

3).

Tighten the screws (torque 1.2 Nm).

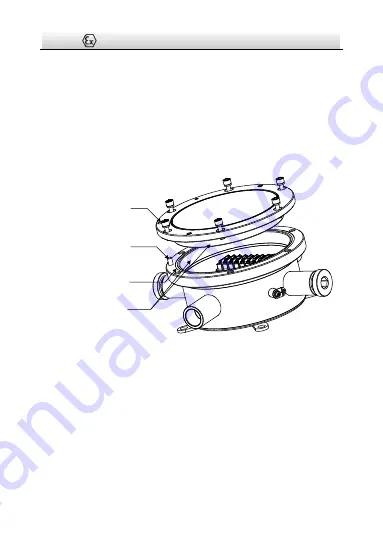

Locating Hole

Locating Pin

O-Shape Ring

Explosion Suppression

Surface

Torque 1.2 Nm

Figure 3-6

Install Cover Back

3.2

DS-2780 and DS-2782 Series Installation

Steps:

1.

Drill four screw holes (Ø8 mm) according to the dimension of the

terminal box (see Figure 2-1), and insert four M8 × 80 expansion

bolts.

2.

Secure the terminal box on mounting place.