6/00

WARRANTY

HEREINAFTER REFERRED TO AS MANUFACTURER

FOURTEEN MONTH WARRANTY. MANUFACTURER’S PRODUCT IS WARRANTED TO BE FREE FROM

DEFECTS IN MATERIAL AND WORKMANSHIP UNDER NORMAL USE AND MAINTENANCE FOR A

PERIOD OF FOURTEEN MONTHS FROM THE DATE OF ORIGINAL SHIPMENT. A NEW OR REBUILT

PART TO REPLACE ANY DEFECTIVE PART WILL BE PROVIDED WITHOUT CHARGE, PROVIDED THE

DEFECTIVE PART IS RETURNED TO MANUFACTURER. THE REPLACEMENT PART ASSUMES THE

UNUSED PORTION OF THE WARRANTY.

This warranty does not include labor or other costs incurred for repairing, removing, installing, shipping,

servicing, or handling of either defective parts or replacement parts.

The fourteen month warranty shall not apply:

1. To any unit or any part thereof which has been subject to accident, alteration, negligence, misuse or

abuse, operation on improper voltage, or which has not been operated in accordance with the

manufacturer’s recommendation, or if the serial number of the unit has been altered, defaced, or removed.

2. When the unit, or any part thereof, is damaged by fire, flood, or other act of God.

3. Outside the continental United States.

4. To labor cost for replacement of parts, or for freight, shipping expenses, sales tax or upgrading.

5. When the operation is impaired due to improper installation.

6. When installation and startup forms are not properly complete or returned within two weeks after startup.

THIS PLAN DOES NOT COVER CONSEQUENTIAL DAMAGES. Manufacturer shall not be liable under any

circumstances for any consequential damages, including loss of profit, additional labor cost, loss of

refrigerant or food products, or injury to personnel or property caused by defective material or parts or for

any delay in its performance hereunder due to causes beyond its control. The foregoing shall constitute

the sole and exclusive remedy of any purchases and the sole and exclusive liability of Manufacturer in

connection with this product.

The Warranties are Expressly in Lieu of All Other Warranties, Express of Implied and All Other

Obligations or Liabilities on Our Part. The Obligation to Repair or Replace Parts or Components

Judged to be Defective in Material or Workmanship States Our Entire Liability Whether Based on Tort,

Contract or Warranty. We Neither Assume Nor Authorize Any Other Person to Assume for Us Any

Other Liability in Connection with Our Product.

MAIL CLAIM TO:

Hill PHOENIX

Display Merchandisers

1925 Ruffin Mill Road

Colonial Heights, VA 23834

804-526-4455

Hill PHOENIX

Refrigeration Systems &

Electrical Distribution Products

709 Sigman Road

Conyers, GA 30013

770-285-3200

Summary of Contents for KRZH

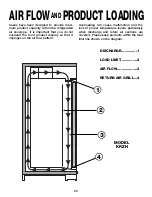

Page 2: ......

Page 4: ......

Page 16: ...12 WIRING DIAGRAMS MODEL KRZH 2 DOOR ...

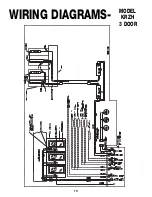

Page 17: ...13 WIRING DIAGRAMS MODEL KRZH 3 DOOR ...

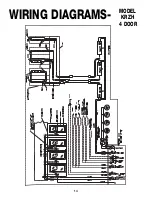

Page 18: ...14 WIRING DIAGRAMS MODEL KRZH 4 DOOR ...

Page 19: ...15 WIRING DIAGRAMS MODEL KRZH 5 DOOR ...

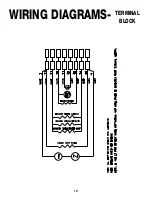

Page 20: ...16 WIRING DIAGRAMS TERMINAL BLOCK ...

Page 21: ...17 WIRING DIAGRAMS GFI ...