10

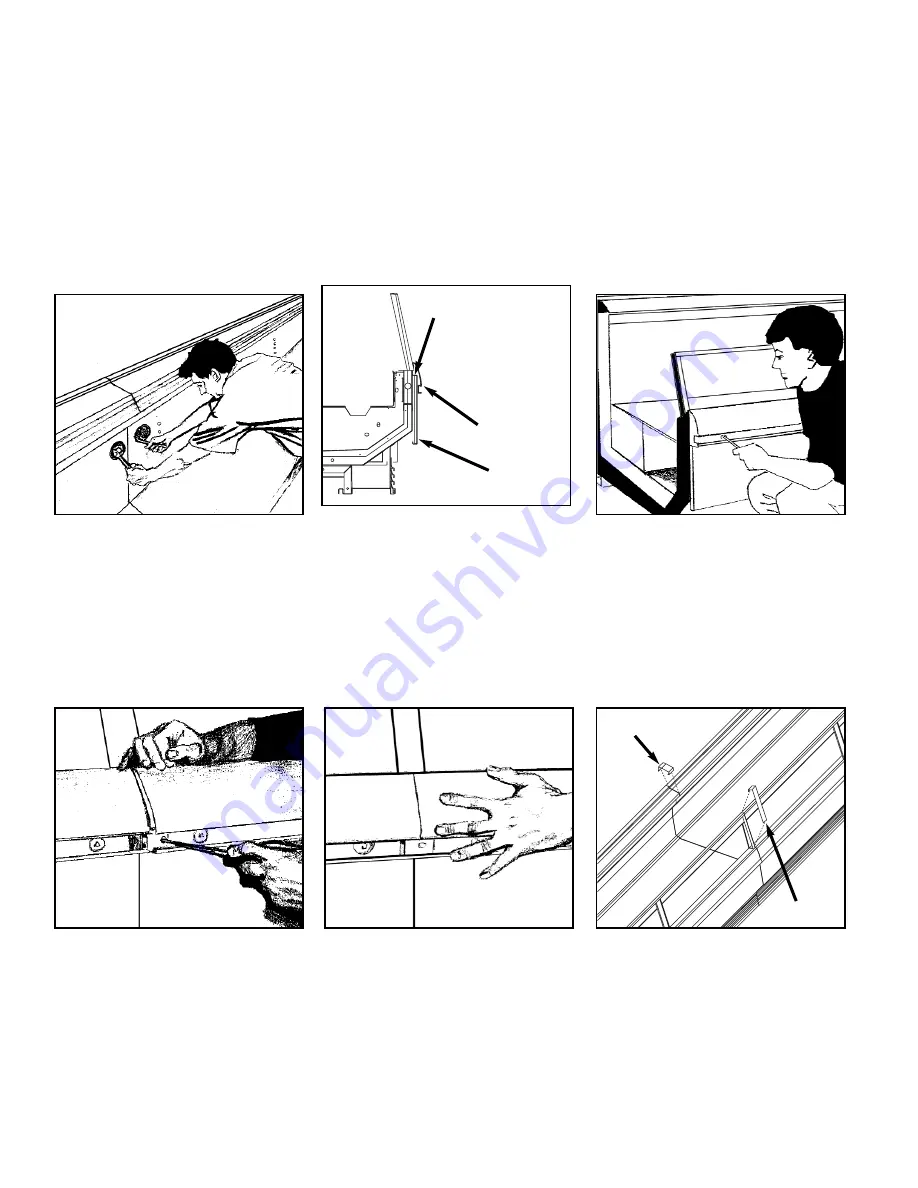

TRIM OUT

Now that cases have been positioned and leveled, you may proceed to trim-out

case lineup. Trim parts have been designed to be applied easily with only a small

number of fasteners required. Most external parts are adjustable to achieve almost

invisible, snug-fitting joints and a high level of excellence in fit and finish.

6

Install joint covers over case-to-case

joint seams, as needed. All case joint

pieces are shipped loose with the case.

Secure with fasteners provided.

;;;

;;;

;;;

;;;

;;;

;;;

;;;

;;;

;;;

;;;

5

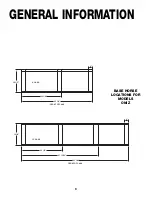

Slide bumper left or right to close

seam as required. Bumper joint neat-

ly finishes any gap that may remain.

4

Slide bumper joint to center of joint

between the two cases. Use screw

driver in hole provided.

3

Adjust polymer master bumper joints,

if required. First loosen bumper

screws located in recessed trough.

2

If a gap is present in the front panels,

the master bumper must be removed

to gain access to the adjustment

screws. Loosen the screws located

on top of the front panel underneath

the master bumper, and adjust left or

right as required.

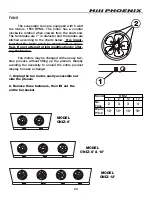

1

Tighten all joint bolts. Draw up tight-

ly, but do not over tighten.

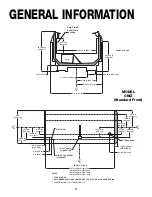

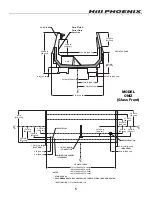

COLOR BAND ADJUSTMENT

SCREWS LOCATED UNDER

MASTER BUMPER

MASTER BUMPER

FRONT PANEL

REAR SILL

JOINT

GLASS

JOINT

Summary of Contents for ORIGIN2 ONIZ

Page 2: ......

Page 4: ......

Page 6: ...2...

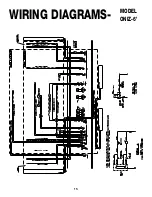

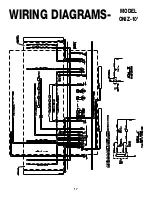

Page 19: ...15 WIRING DIAGRAMS MODEL ONIZ 6...

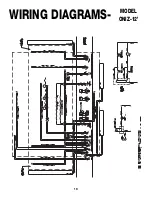

Page 20: ...16 WIRING DIAGRAMS MODEL ONIZ 8...

Page 21: ...17 WIRING DIAGRAMS MODEL ONIZ 10...