23

1

2

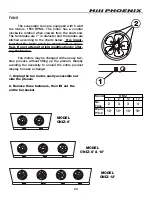

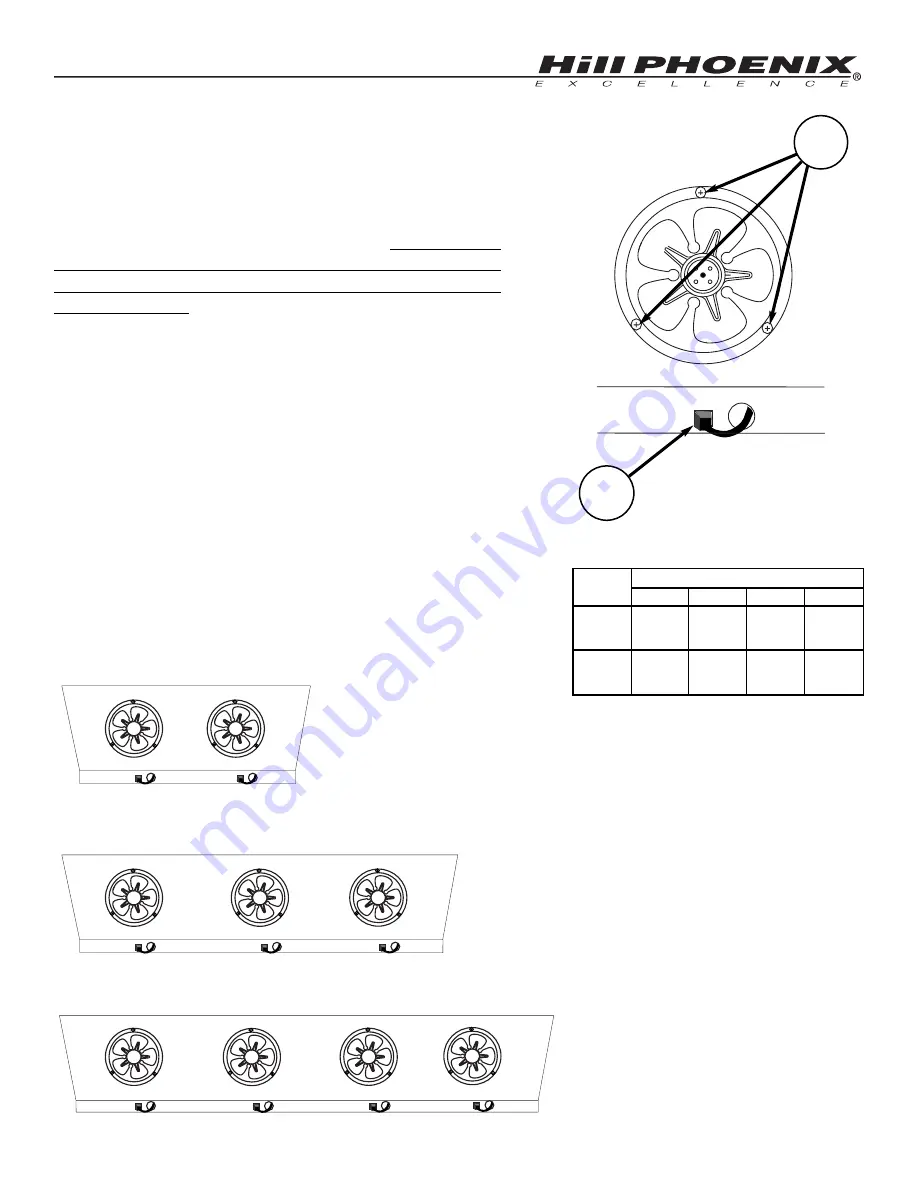

MODEL

ONIZ-8’ & 10’

MODEL

ONIZ-12’

FANS

The evaporator fans are equipped with 5 watt

fan motors, 1550 RPM’s. The motor has a counter

clockwise rotation when viewed from the shaft end.

The fan blades are 7” in diameter and the blades are

pitched according to the charts below.

It is impor-

tant that the blade pitch be maintained as speci-

fied. Do not attempt a field modification by alter-

ing the blades.

Fan motors may be changed with an easy two-

step process without lifting up the plenum, thereby

avoiding the necessity to unload the entire product

display to make a change:

1. Unplug the fan motor, easily accessible out

side the plenum

2. Remove three fasteners, then lift out the

entire fan basket

Model ONIZ

No.

Fans

Blade

Pitch

8’

3

10

o

6’

2

10

o

10’

3

10

o

12’

4

10

o

MODEL

ONIZ-6’

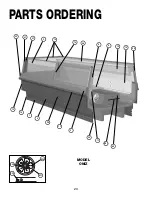

Summary of Contents for ORIGIN2 ONIZ

Page 2: ......

Page 4: ......

Page 6: ...2...

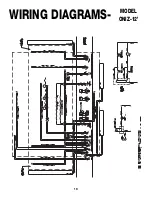

Page 19: ...15 WIRING DIAGRAMS MODEL ONIZ 6...

Page 20: ...16 WIRING DIAGRAMS MODEL ONIZ 8...

Page 21: ...17 WIRING DIAGRAMS MODEL ONIZ 10...